Polyester film, laminated film, and solar-cell back sheet and solar cell both including same

A technology of solar cells and polyester films, which is applied in the field of polyester films, can solve problems such as hydrolysis degradation and reduced heat and humidity resistance, and achieve high durability, excellent time and high heat and humidity resistance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

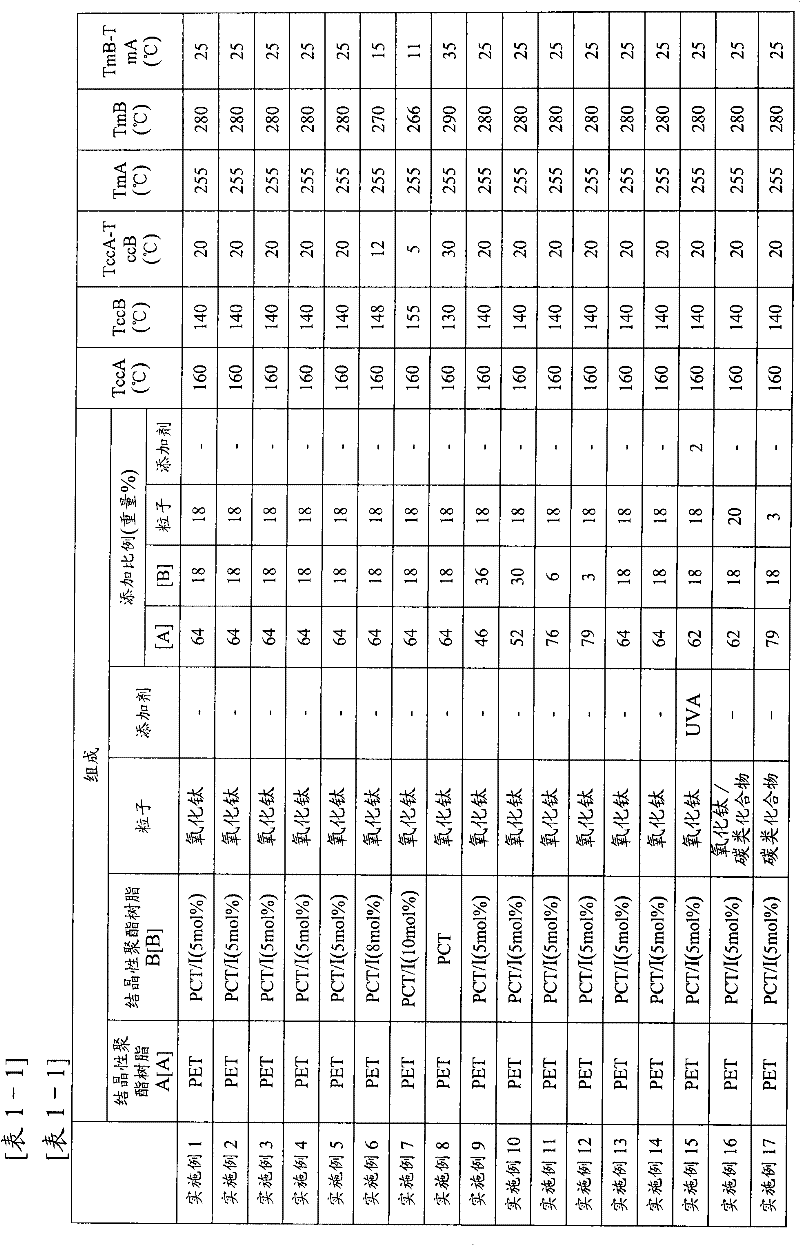

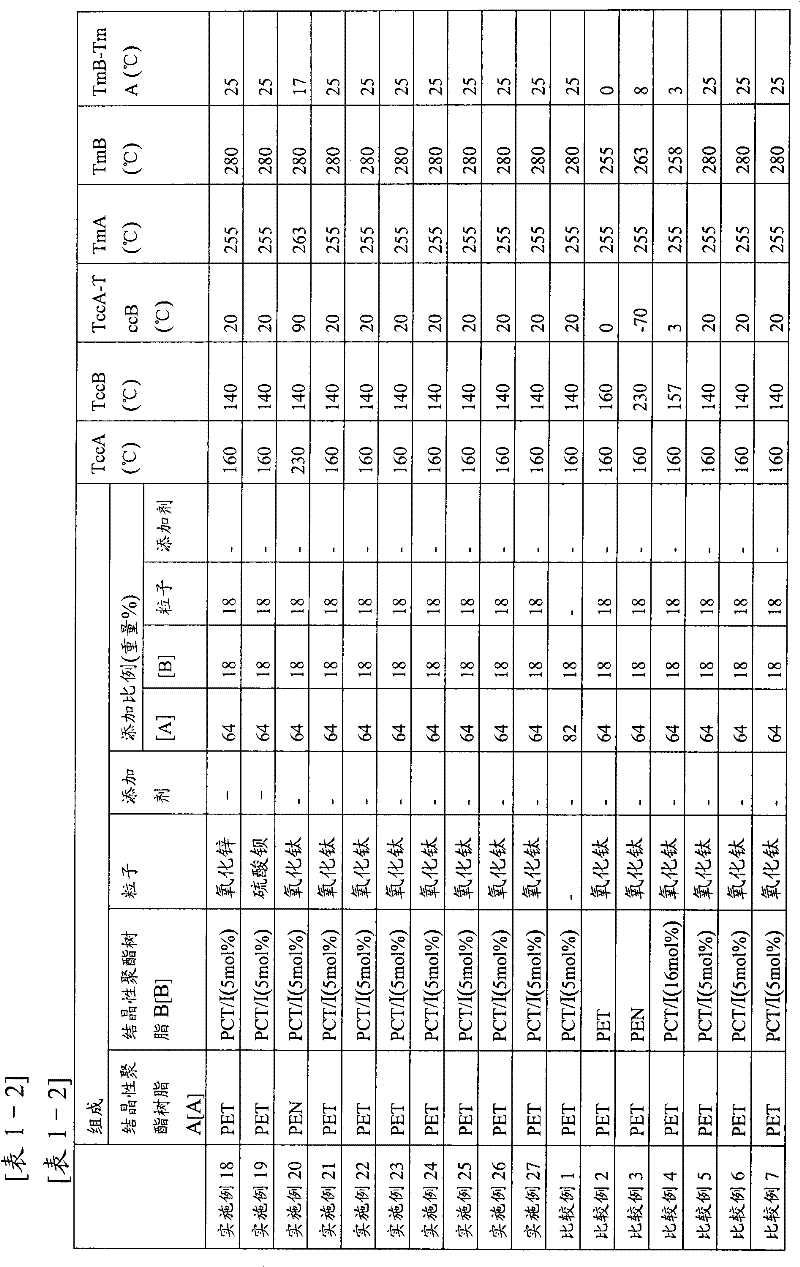

Embodiment 1

[0190] Using 100 mol% of terephthalic acid as a dicarboxylic acid component, 100 mol% of ethylene glycol as a glycol component, and using magnesium acetate, antimony trioxide, and phosphorous acid as a catalyst, the polycondensation reaction was carried out. Then, the obtained polyethylene terephthalate was dried at 160°C for 6 hours to make it crystallized, and then solid-phase polymerized at 220°C and a vacuum of 0.3 Torr for 9 hours to obtain a polyethylene terephthalate with a melting point of 255°C. Ethylene terephthalate (PET) (crystalline polyester resin A). Next, use 95mol% terephthalic acid, 5mol% isophthalic acid as the dicarboxylic acid component, use 100mol% cyclohexanedimethanol as the glycol component, and use magnesium acetate, antimony trioxide, and phosphorous acid as the catalyst to carry out Polycondensation reaction to obtain polycyclohexanedimethylene terephthalate (PCT / I5mol%) (crystalline polyester resin B) containing 5 mol% isophthalic acid having a mel...

Embodiment 2~5、21、22

[0194]A biaxially stretched film was obtained in the same manner as in Example 1, except that the stretch ratio was changed as shown in Table 1 in the film production process. The resulting film was evaluated as follows: the flatness of the dispersed phase of the crystalline polyester resin B, the ratio of titanium oxide particles present in or in contact with the dispersed phase of the crystalline polyester resin B, the average relative reflectance, and the heat and humidity resistance test. Evaluation of mechanical properties and mechanical properties after light resistance test. As a result, as shown in Table 1, it was a film with good heat-and-moisture resistance, light resistance, and light reflectivity, and it was found that the film with higher flatness of crystalline polyester resin B was a film with better heat-and-moisture resistance. In addition, using the above-mentioned film, a solar battery back sheet was produced in the same manner as in Example 1, and the moist...

Embodiment 6

[0196] Use 92mol% terephthalic acid, 8mol% isophthalic acid as the dicarboxylic acid component, use 100mol% cyclohexanedimethanol as the glycol component, and use magnesium acetate, antimony trioxide, and phosphorous acid as the catalyst to carry out the polycondensation reaction, In the same manner as in Example 1, except that polycyclohexanedimethylene terephthalate (PCT / I 8 mol%) containing 8 mol% of isophthalic acid having a melting point of 270° C. was used as the crystalline polyester resin B get the film. The resulting film was evaluated as follows: the flatness of the dispersed phase of the crystalline polyester resin B, the ratio of titanium oxide particles present in or in contact with the dispersed phase of the crystalline polyester resin B, the average relative reflectance, and the ratio after the heat and humidity resistance test. Evaluation of mechanical properties and mechanical properties after the light resistance test. As a result, as shown in Table 1, it wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com