Semi-aromatic polyamide polyester copolymer and preparation method thereof

A semi-aromatic polyamide and copolymer technology, applied in the field of semi-aromatic polyamide polyester copolymer and its preparation, can solve the problems of low conversion rate, poor water absorption and mechanical properties, achieve less side reactions and improve heat resistance Sex, molecular structure controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

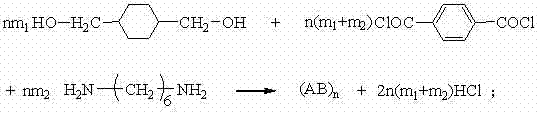

[0022] The present invention also provides a preparation method of the semi-aromatic polyamide polyester copolymer, comprising the following steps:

[0023] 1) Dissolve 1,4-cyclohexanedimethanol and hexamethylenediamine in water at an equimolar ratio to obtain a mixed solution; add an acid absorbent to the mixed solution, and ensure that the temperature of the mixed solution is 5-25°C;

[0024] 2) Dissolve terephthaloyl chloride in dichloromethane to obtain a terephthaloyl chloride solution; under stirring, add the terephthaloyl chloride solution dropwise to the mixed solution in step 1); continue stir;

[0025] 3) The product of step 2) is filtered, washed with water and ammonia water, and dried to obtain the semi-aromatic polyamide polyester copolymer.

[0026] The preparation method provided by the present invention adopts 1,4 cyclohexanedimethanol, hexamethylenediamine and terephthaloyl chloride as monomers, and undergoes esterification and polycondensation reaction of 1,...

Embodiment 1

[0041] In a 1L four-necked flask equipped with a stirrer, a dropping funnel, a thermometer and an inlet, put 7.21g (0.05mol) of 1.4-cyclohexanedimethanol and 5.81g (0.05mol) of hexamethylenediamine and 8g ( 0.2mol) of sodium hydroxide was dissolved in 500ml of water, and the temperature of the solution inside the flask was kept at 15°C.

[0042] Dissolve 20.3g (0.1mol) of terephthaloyl chloride and 0.14g (0.001mol) of benzoyl chloride in 130ml of dichloromethane in a beaker, and add the resulting solution to the dropping funnel of the four-necked flask; stirring Next, the solution in the dropping funnel was added dropwise into the four-necked flask, and the dropwise addition was completed within 2 minutes; after the dropping, continued high-speed stirring for 10 minutes.

[0043] The product in the four-necked flask was filtered, and the filter residue was washed with 500 ml of deionized water for 3 min under stirring; the washing was repeated 3 times. Then wash with 500 ml o...

Embodiment 2

[0046] The semi-aromatic polyamide polyester copolymer S2 of this example was prepared by the same steps as in Example 1, except that the amount of 1,4-cyclohexanedimethanol was 1.442 g (0.01 mol), and the amount of hexamethylenediamine The dosage is 10.458g (0.09mol).

[0047] Through the above steps, the product semi-aromatic polyamide polyester copolymer S2 was obtained; weighing 23.9g, the conversion rate was 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com