High-stability Cu-based catalyst and preparation method thereof

A high-stability, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as poor catalyst stability and environmental pollution, and achieve reduction Effects of acidity, increased reduction temperature, and enhanced interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

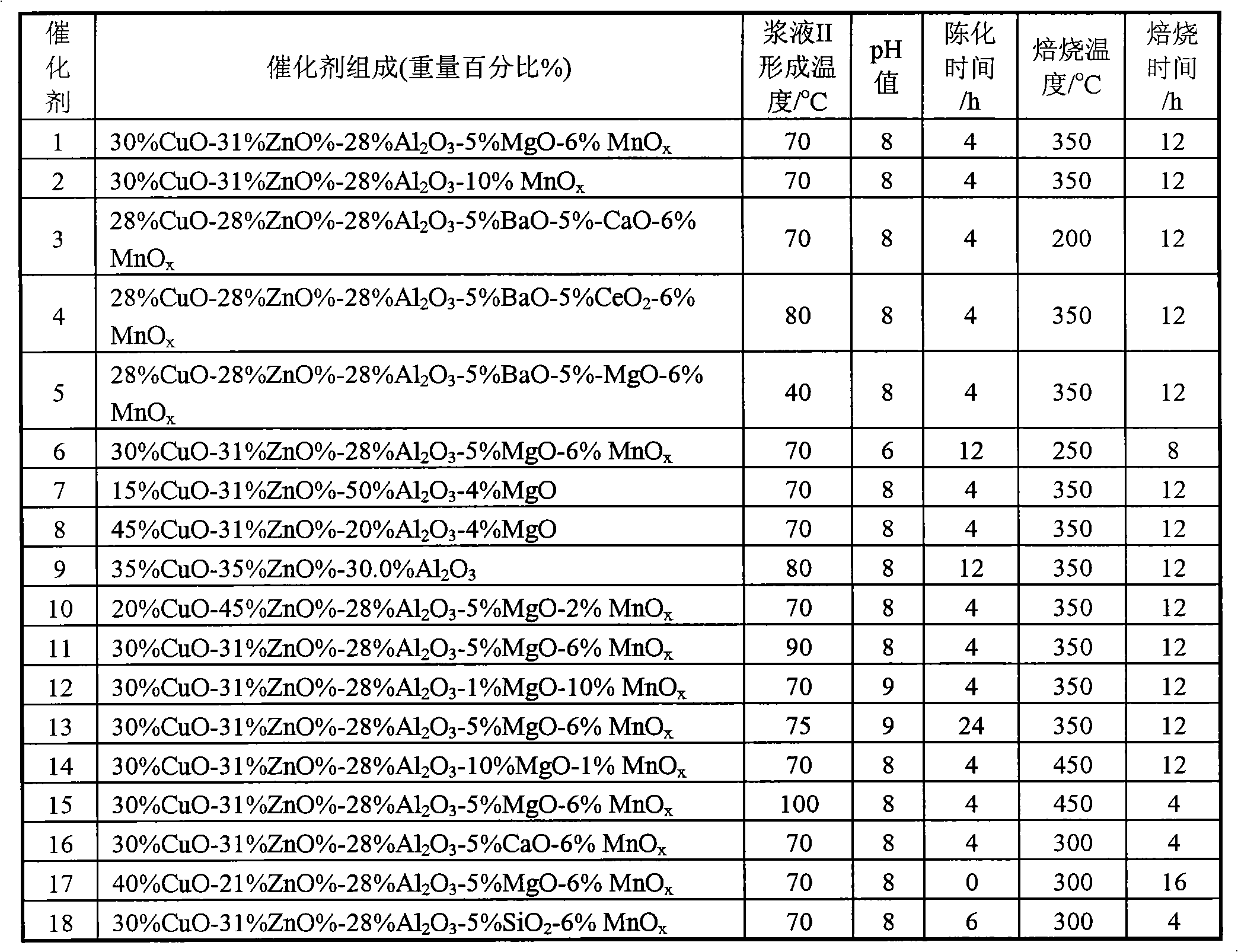

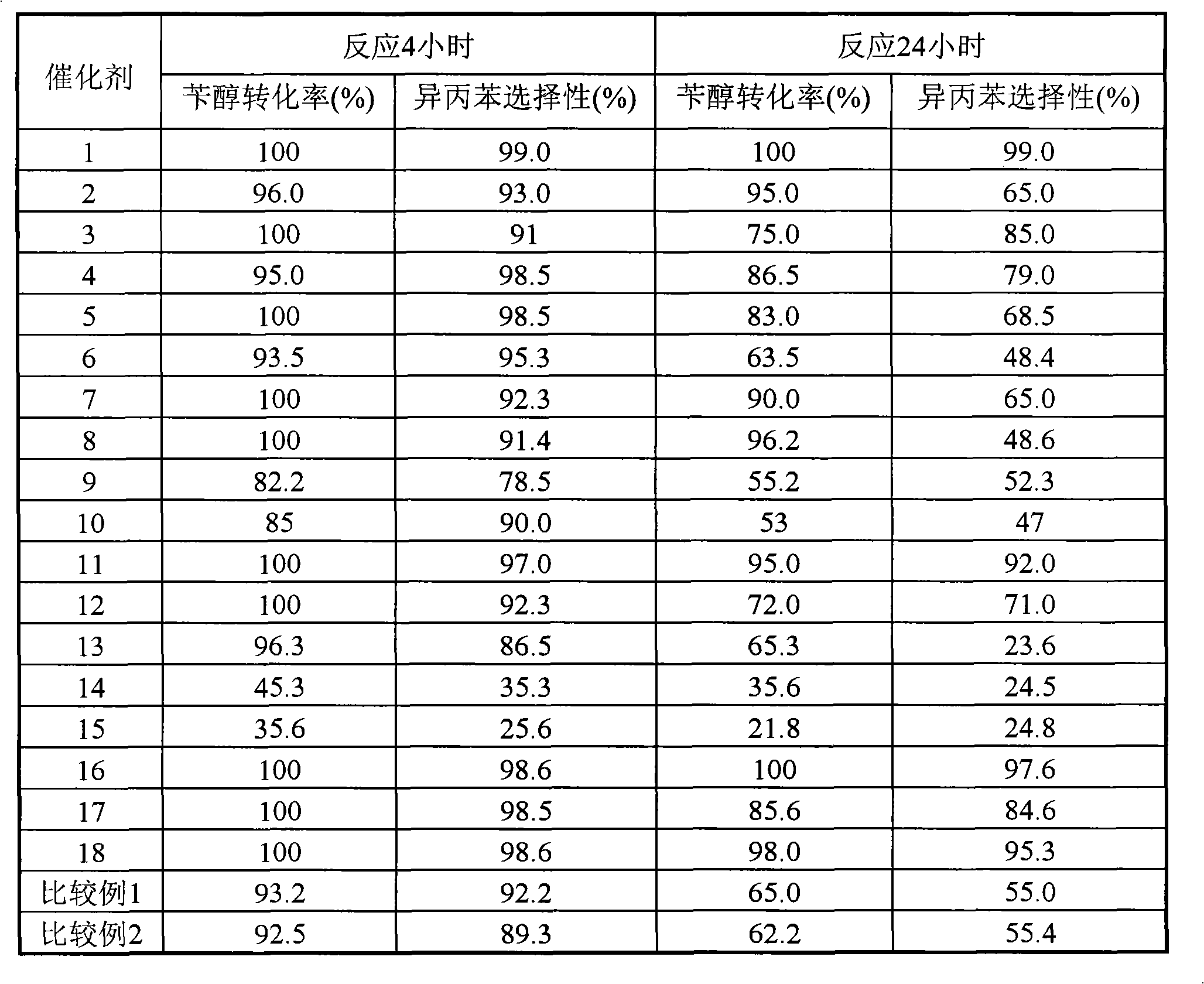

[0014] Catalyst 1 uses an appropriate amount of Mg(NO 3 ) 2 The solution was impregnated with equal volume, dried and calcined at 600 °C to obtain MgO-modified Al 2 o 3 Carrier, after pulverizing the carrier, mix it with water and beating to obtain slurry I, drop the required amount of mixed solution of copper nitrate, zinc nitrate and manganese nitrate and 1.0mol / L sodium carbonate aqueous solution into slurry I at the same time for co-precipitation to form slurry II. The precipitation temperature is 70°C, and the pH value of the solution is controlled to be 8.0. After the solution is added dropwise, it is aged at 70°C for 4 hours, then the precipitate is washed and filtered, dried at 120°C for 12 hours, calcined at 350°C for 4 hours, and pressed into tablets Forming obtains catalyst 1 (the composition of catalyst is by weight percent: 30%CuO-31%ZnO%-28%Al 2 o 3 -5%MgO-6%MnOx) Embodiment 2~15 (corresponding catalyst 2~15), prepare catalyst according to each step among the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com