Method for modifying molecular sieve

A molecular sieve, hydrogen-type molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, can solve the problems of complicated operation, intermittent operation, affecting the performance of use, etc., and achieve the effect of improving processing efficiency, avoiding high temperature burning, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of Modified ZSM-5 Molecular Sieve (E-1)

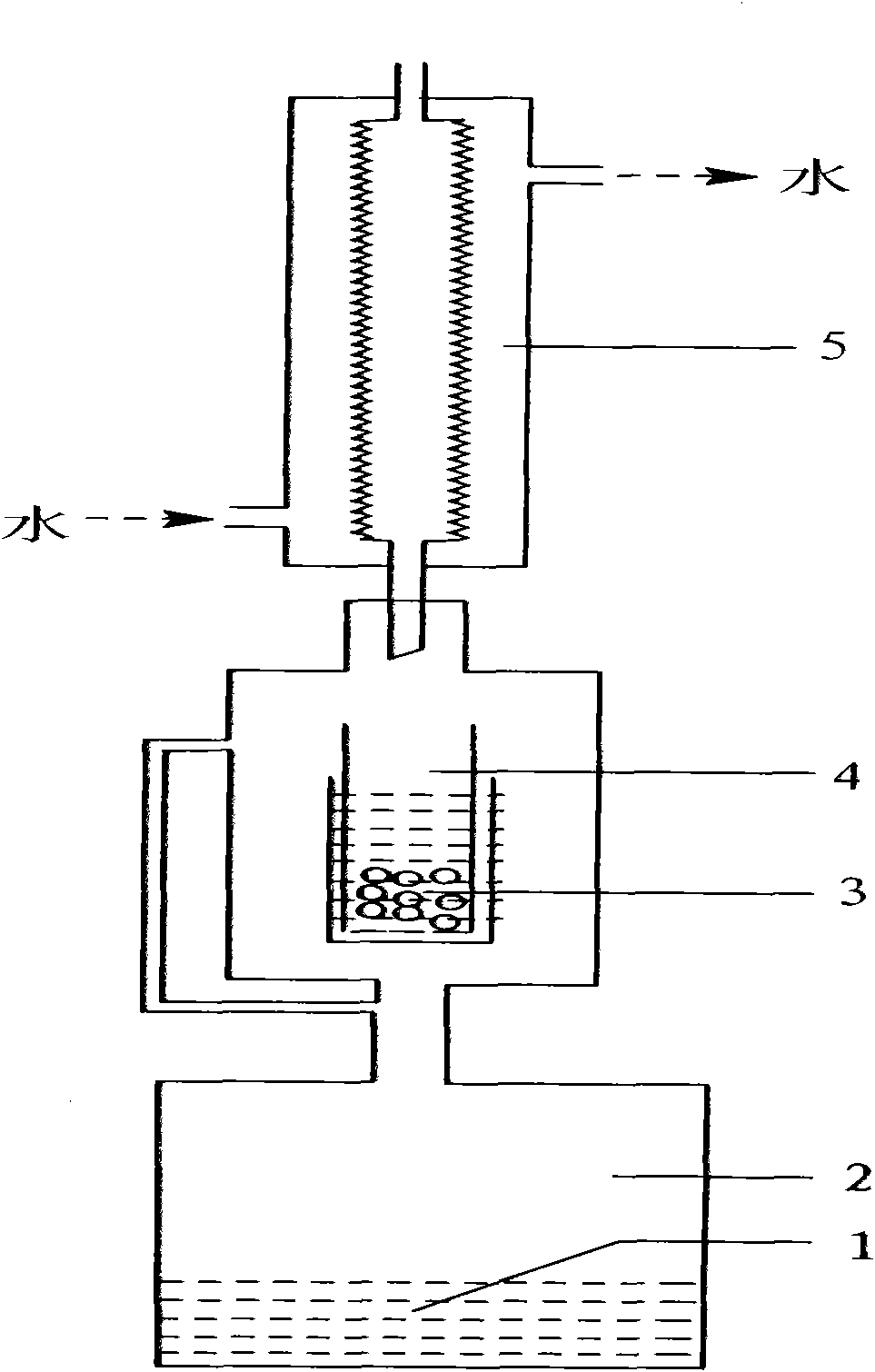

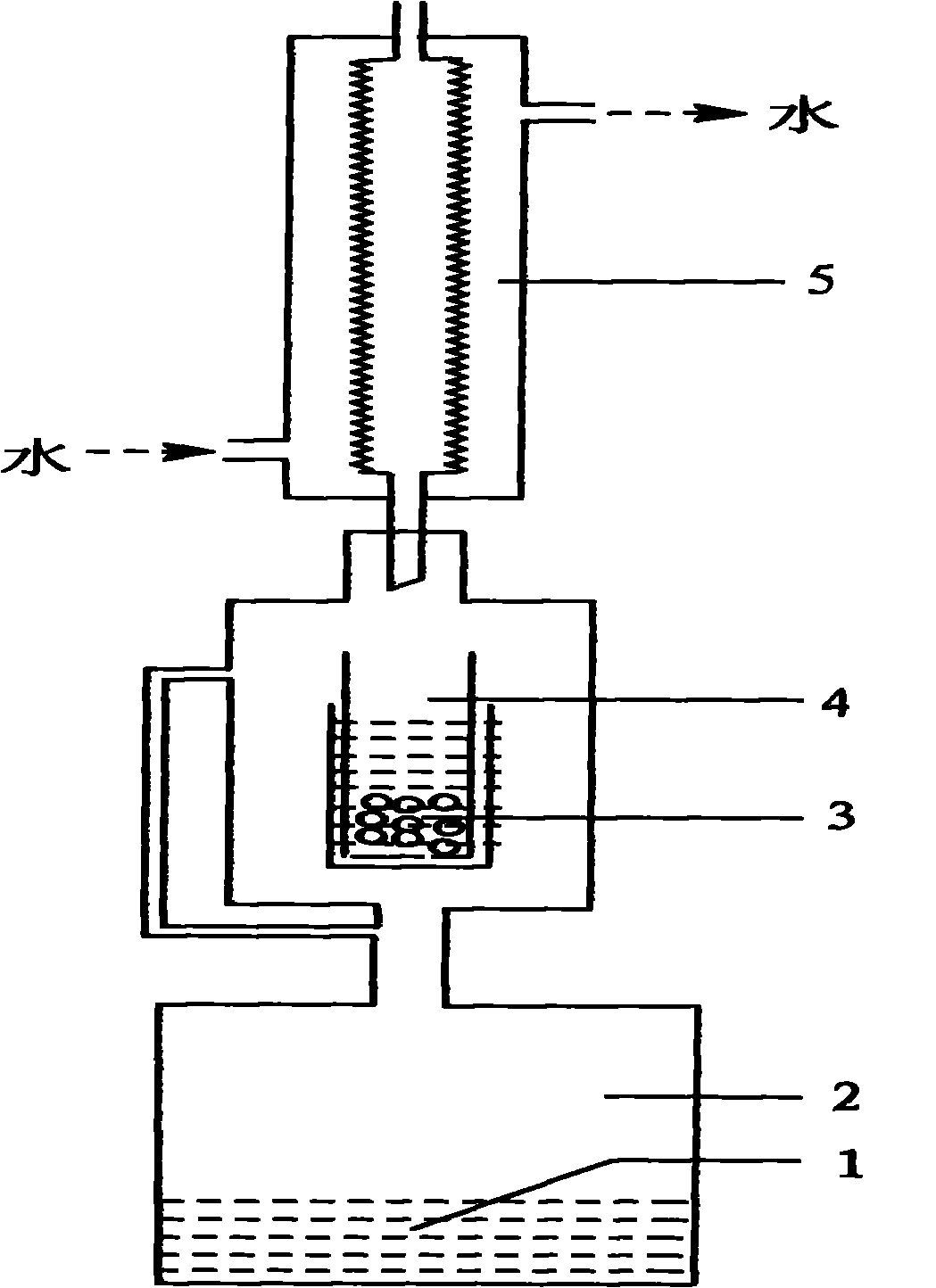

[0023] The process of this method is as follows:

[0024] (1) Get 100 grams of ZSM-5 former powder (0.8 mass % of nitrogen content, 2.8 mass % of sodium content) and place it in the sample pool 4, add 500 milliliters of toluene in the distiller 2, heat to make the toluene boil, and reflux for 6 hours, After the sample was dried, the nitrogen content was analyzed, and the denitrification rate was calculated (the template agent is a nitrogen-containing compound). The results are shown in Table 1.

[0025] (2) Get the sample obtained through step (1) and place it in the sample pool 4, add 500 milliliters of 3.0% by mass hydrochloric acid in the distiller 2, heat the hydrochloric acid to boil, reflux for 8 hours, and analyze its relative strength after the sample is dried. The crystallinity and sodium content were used to calculate the sodium removal rate, and the results are shown in Table 1.

Embodiment 2

[0027] Preparation of Modified β Molecular Sieve (E-2)

[0028] The process of this method is as follows:

[0029] (1) Get 100 grams of beta molecular sieve former powder (nitrogen content 1.1% by mass, sodium content 3.2% by mass) and place it in the sample pool 4, add 500 milliliters of chloroform in the distiller 2, heat the chloroform to boil, and reflux After 12 hours, the nitrogen content in the sample was analyzed after drying, and the denitrification rate was calculated. The results are shown in Table 1.

[0030] (2) Get the sample obtained through step (1) and place it in the sample pool 4, add 500 milliliters of 3.0% hydrochloric acid in the distiller 2, heat to make the hydrochloric acid boil, and reflux for 8 hours, and the sample is analyzed after drying. The crystallinity and sodium content were used to calculate the sodium removal rate, and the results are shown in Table 1.

Embodiment 3

[0032] Preparation of Modified ZSM-22 Molecular Sieve (E-3)

[0033] The treatment process was the same as in Example 1, except that ZSM-22 molecular sieve (nitrogen content 0.6% by mass, sodium content 1.6% by mass) replaced ZSM-5 molecular sieve. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com