Green synthetic method for rare earth-containing ZSM-35 molecular sieve

A ZSM-35, green synthesis technology, applied in the field of material chemistry and catalytic chemistry, can solve the problems of complex process operation, high production cost, serious environmental pollution, etc., and achieve simple operation process, good crystallization quality, and simplified process operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

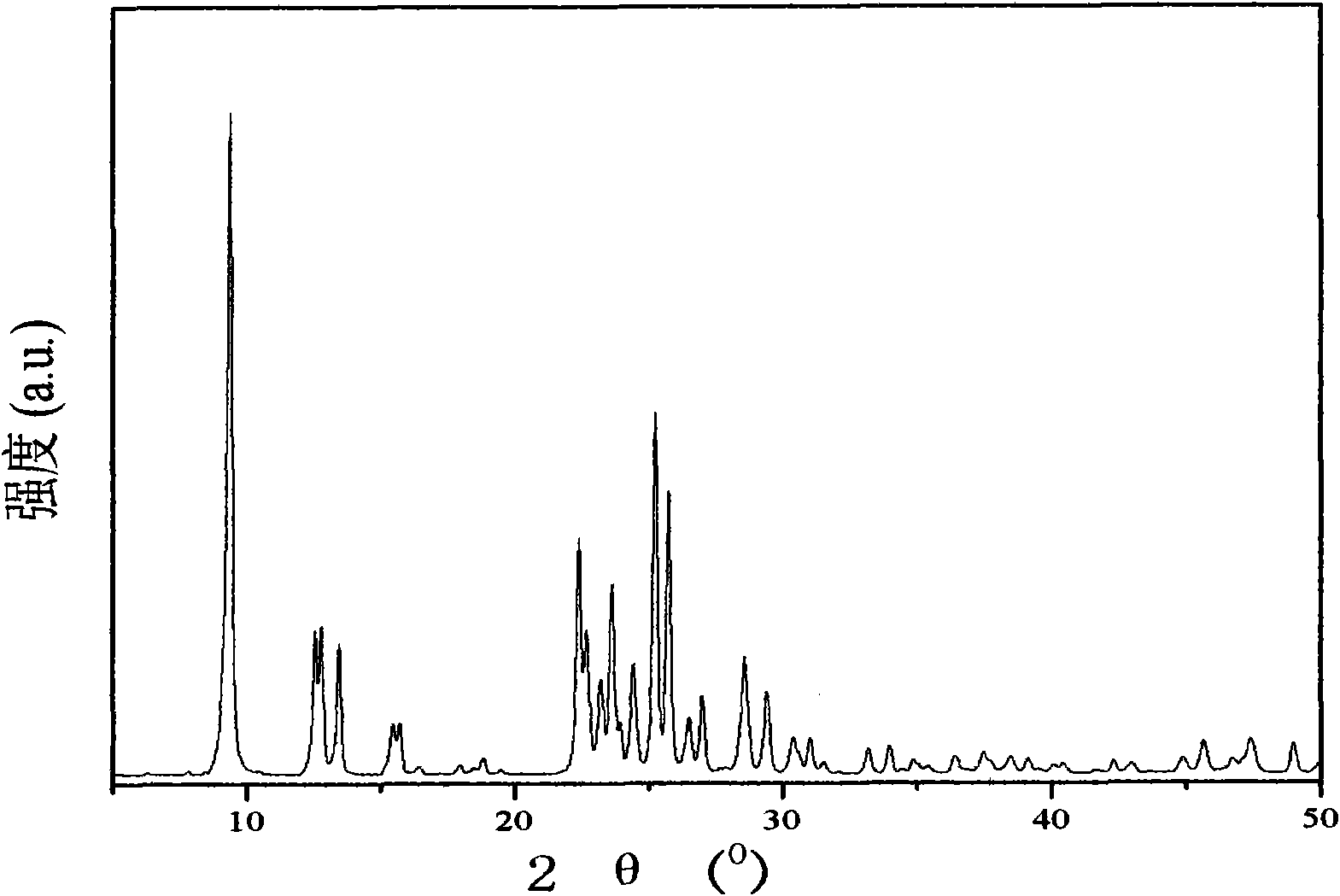

Embodiment 1

[0019] (1) Raw material

[0020] A. Silica sol (25.7wt% SiO 2 , 0.3wt%Na 2 O, 0.1wt%Al 2 o 3 ): 59.67g;

[0021] B. Sodium metaaluminate solution (NaAlO 2 : 16.8wt%Al 2 o 3 , 31.2wt% NaOH): 7.37g;

[0022] C. dilute sulfuric acid (25.6wt%H 2 SO 4 ): 1.40g;

[0023] D. Deionized water: 156.5g;

[0024] E. ZSM-35 seed crystal: 0.03g;

[0025] F. Lanthanum nitrate [La(NO 3 ) 3 ·6H 2 O]: 0.11g;

[0026] The molar composition of the reaction mixture is: SiO 2 / Al 2 o 3 =20,OH - / Al 2 o 3 = 4.4, H 2 O / Al 2 o 3 =900, La 2 o 3 / Al 2 o 3 =0.01, the seed crystal addition amount is 0.2% of the raw material silicon aluminum oxide mass.

[0027] (2) Operation steps:

[0028] In the case of stirring, add raw material B, 111.5g deionized water (a part of raw material D), raw material A, raw material C and raw material F to the stainless steel reactor in sequence, and continue to stir to make it mix evenly; then add raw material E to 45.0 g g deionized water, af...

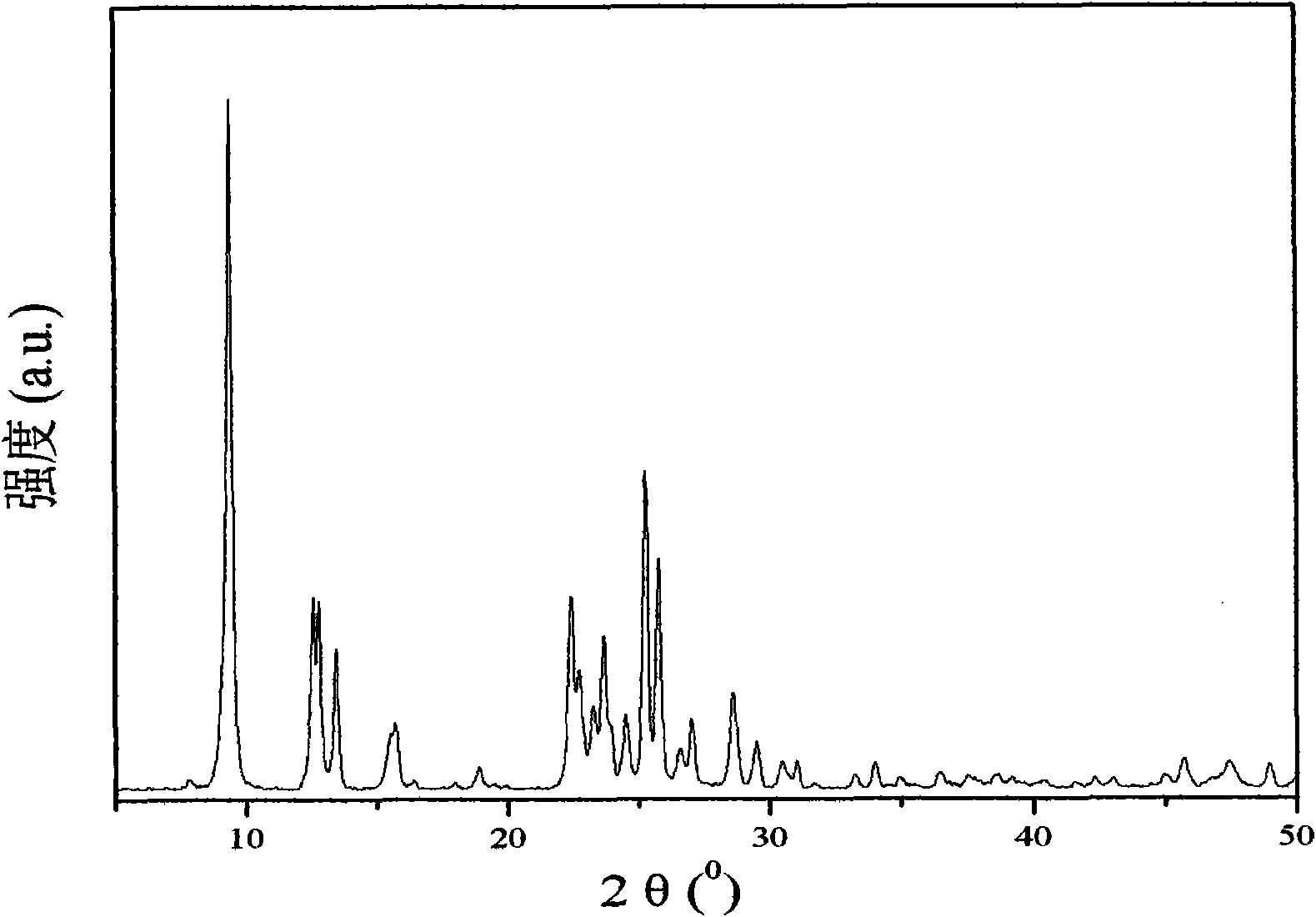

Embodiment 2

[0030] (1) Raw materials:

[0031] A. Silica (95wt% SiO 2 ): 8.89g;

[0032] B. Sodium metaaluminate solution (NaAlO 2 : 16.8wt%Al 2 o 3 , 31.2wt% NaOH): 3.91g;

[0033] C. Sodium hydroxide solution (0.1g NaOH / ml): 2.23ml;

[0034] D. Deionized water: 135.0g;

[0035] E.ZSM-35 seed crystal: 0.10g

[0036] F. Cerium nitrate [Ce(NO 3 ) 3 ·6H 2 O]: 0.84g

[0037] The molar composition of the reaction mixture is: SiO 2 / Al 2 o 3 =23,OH - / Al 2 o 3 =5.6,H 2 O / Al 2 o 3 =1200, Ce 2 o 3 / Al 2 o 3 =0.15, the amount of seed crystal added is 1.0% of the mass of the raw material silicon aluminum oxide.

[0038](2) Operation steps:

[0039] In the case of stirring, add raw material B, 105.0g deionized water (a part of raw material D), raw material C and raw material F to the stainless steel reaction kettle in sequence, and continue to stir to mix them evenly; then add raw material E to 30g deionized water , after ultrasonic dispersion, add to the above mixture, st...

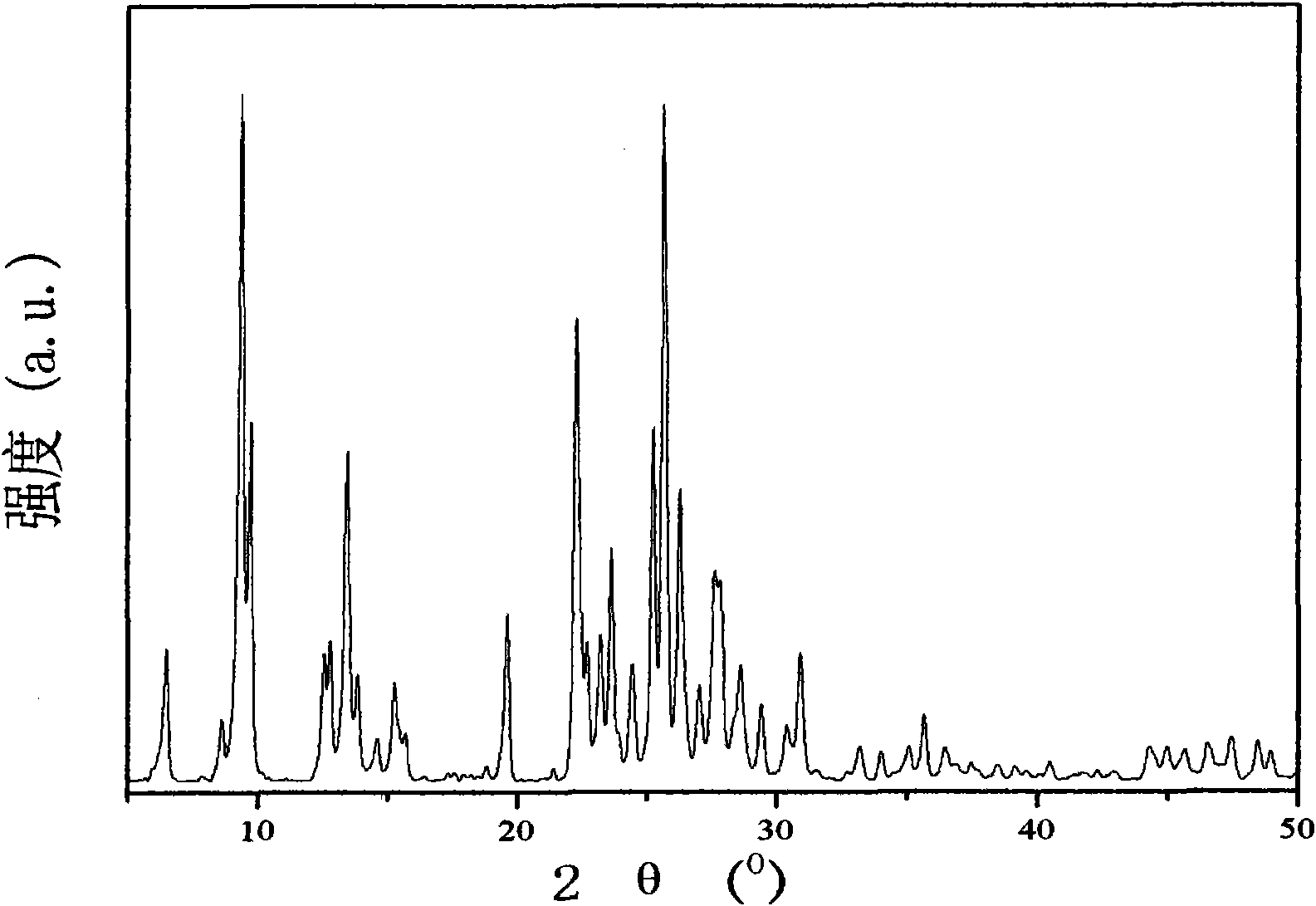

Embodiment 3

[0041] (1) Raw material

[0042] A. Solid silica gel (92wt% SiO 2 ): 10.08g;

[0043] B. Sodium metaaluminate solution (NaAlO 2 : 16.8wt%Al 2 o 3 , 31.2wt% NaOH): 2.34g;

[0044] C. Sodium hydroxide solution (0.1g NaOH / ml): 6.89g;

[0045] D. Deionized water: 130.7g;

[0046] E.ZSM-35 seed crystal: 0.97g;

[0047] F. Lanthanum chloride (LaCl 3 ·6H 2 O): 0.27g;

[0048] The molar composition of the reaction mixture is: SiO 2 / Al 2 o 3 =40,OH - / Al 2 o 3 =9.2,H 2 O / Al 2 o 3 =2000, La 2 o 3 / Al 2 o 3 =0.10, the amount of seed crystal added is 10.0% of the mass of the raw material silicon aluminum oxide.

[0049] (2) Operation steps:

[0050] Under the condition of stirring, add raw material B, 100.7g deionized water (raw material D), raw material C and raw material F to the stainless steel reaction kettle in sequence, continue to stir to make it mix evenly; then add raw material E to 30g deionized water, ultrasonic After dispersing, add it to the above mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com