Device for atomizing seawater to make salt by utilizing natural resources and collecting distilled water

A natural energy and distilled water technology, applied in the field of salt and distilled water production devices, can solve problems such as low efficiency and inability to collect water, and achieve the effects of increasing evaporation area, reducing transportation costs, and improving salt production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The efficiency of sun-dried salt is mainly determined by the speed of water evaporation, and the evaporation of water mainly depends on temperature, airflow speed and evaporation area. The following three factors are used to improve the efficiency of sun-dried salt.

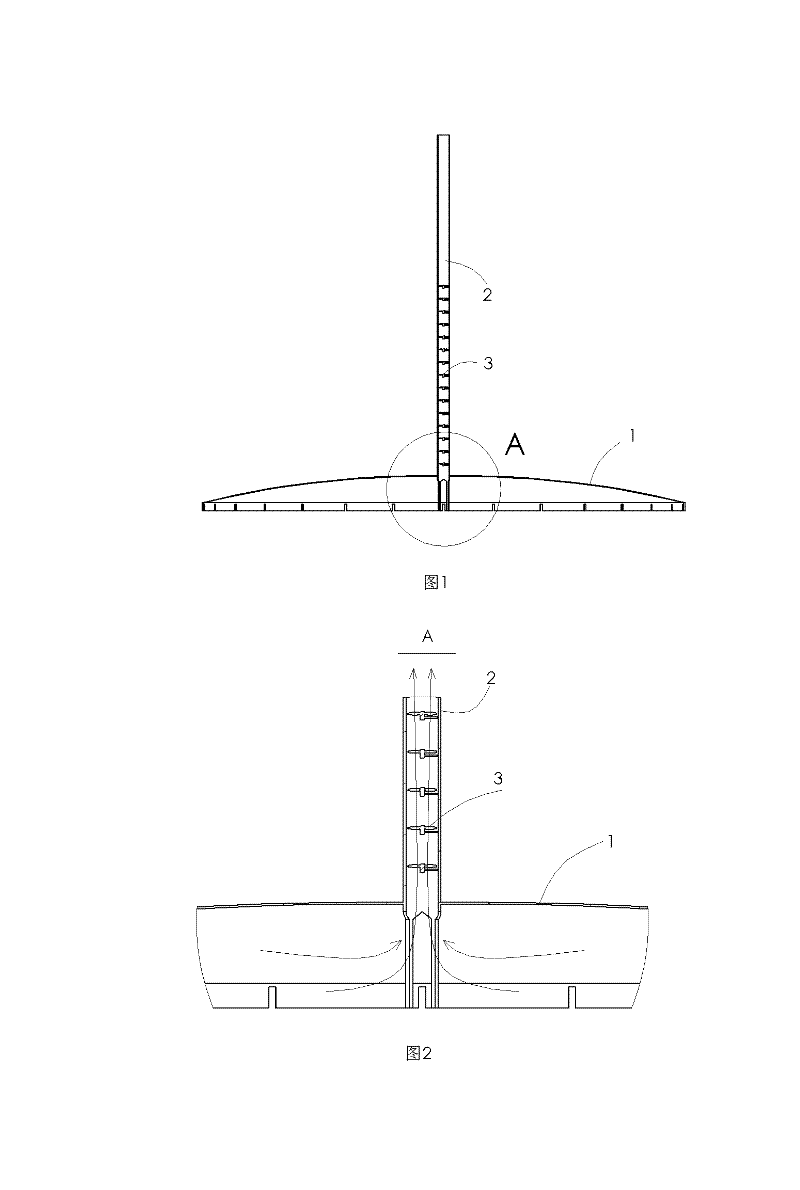

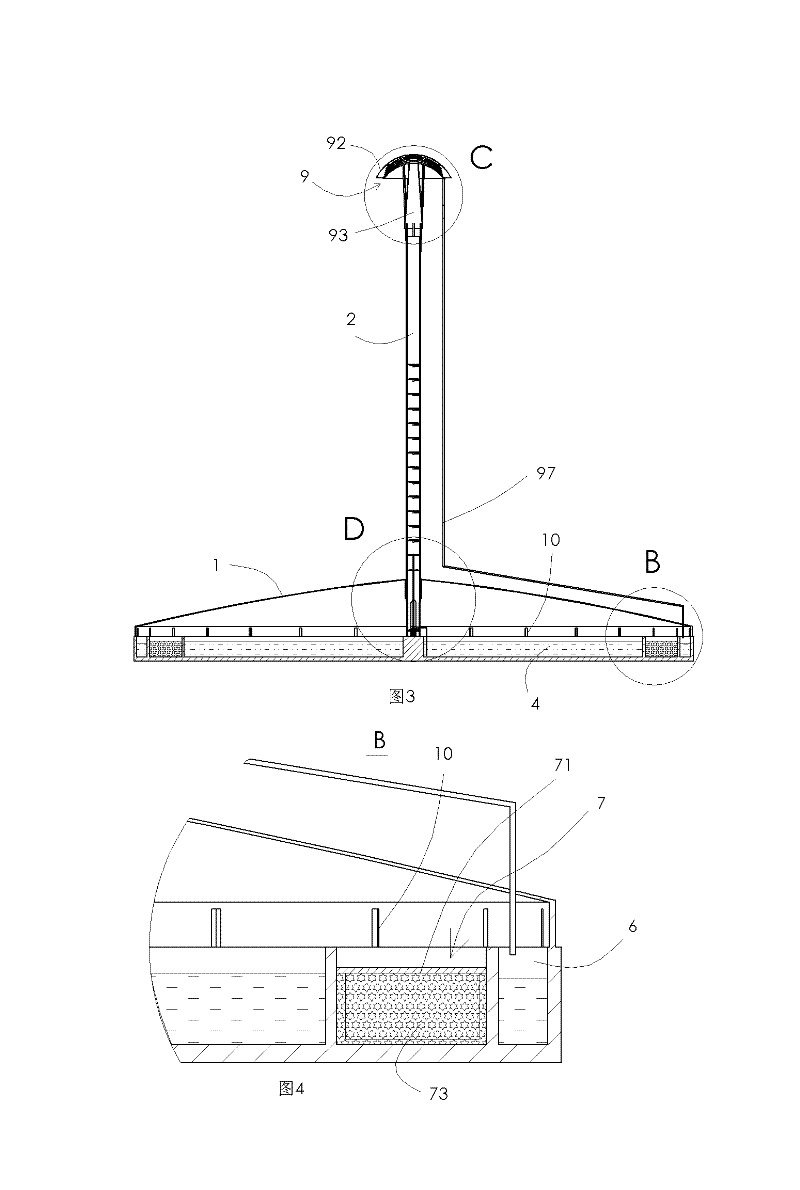

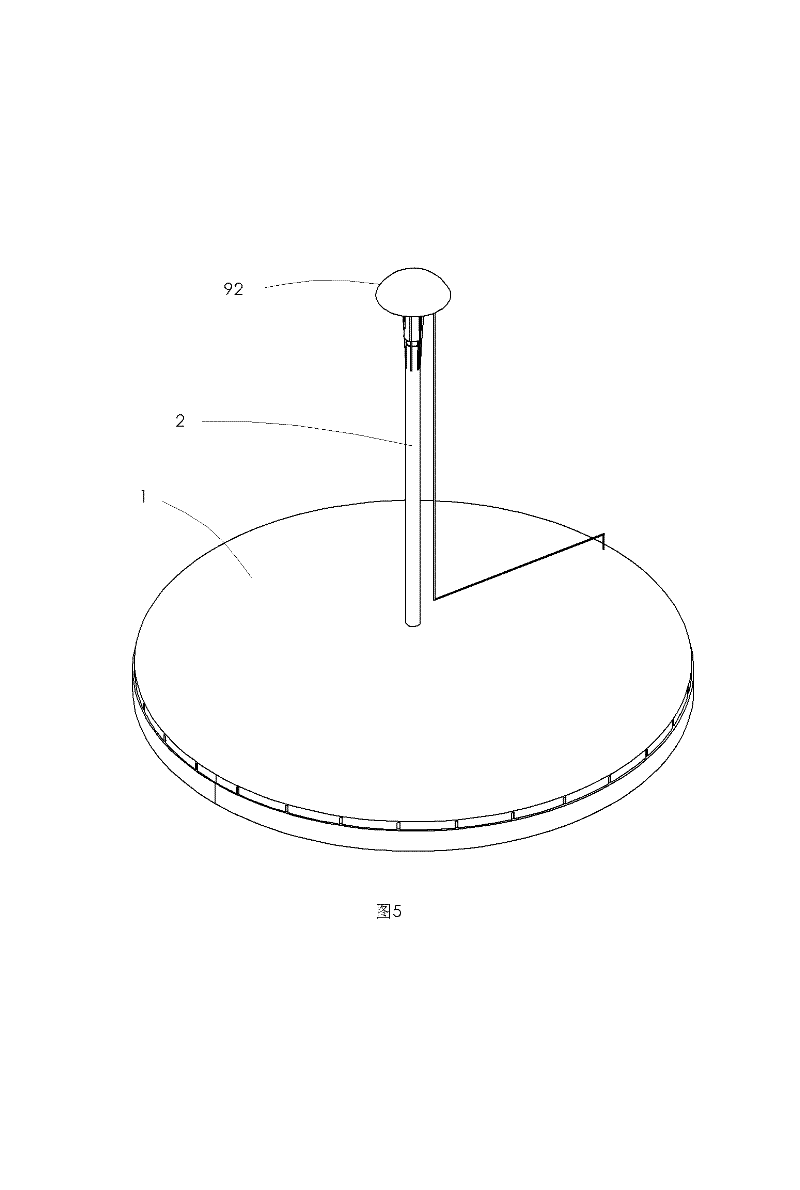

[0034] figure 1 and figure 2 Shown is a solar wind power station in the prior art, which is a device that utilizes hot air generated by solar energy to drive a wind generator to generate electricity. A large-area transparent plastic film greenhouse 1 is laid at the place where the power generation device is located, and the sunlight passes through the film and is absorbed by the ground in the shed. When the sun is sufficient, the air between the film greenhouse and the ground can be heated to 20-50°C. There is a tower-shaped air duct 2 in the center of the greenhouse. The heated air flows into the air duct 2 and then rises along the duct 2 to drive the wind. A plurality of wind power generators 3 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com