Granular carrier for wastewater processing, preparation method thereof and preparation device thereof

A wastewater treatment and preparation device technology, which is applied in the field of water treatment, can solve the problems of difficult microbial attachment and growth, loss, etc., and achieve the effects of good microbial adsorption, fast processing speed, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

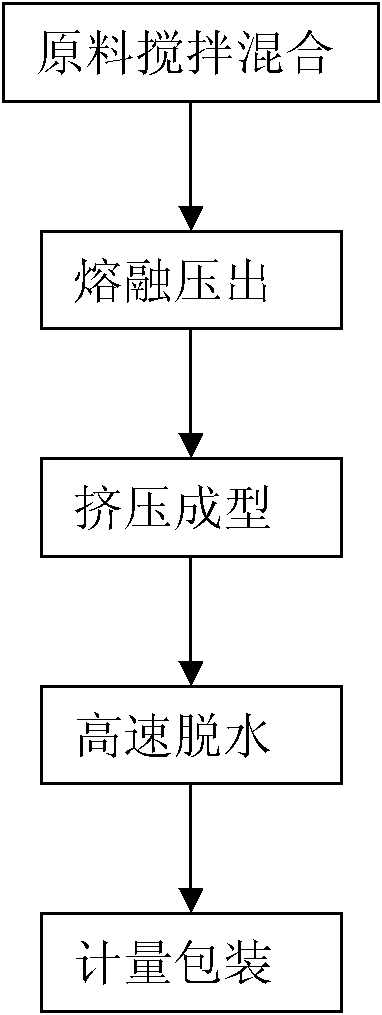

Method used

Image

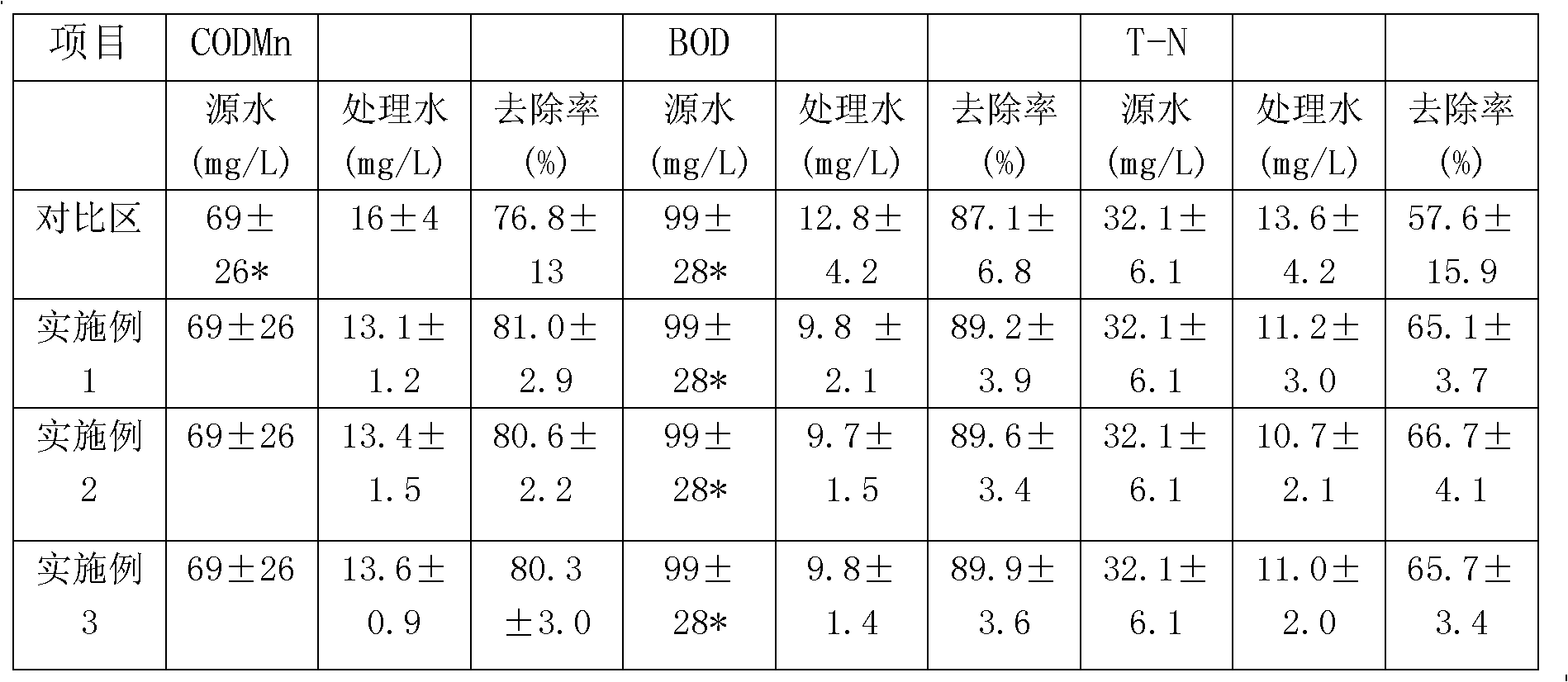

Examples

Embodiment 1

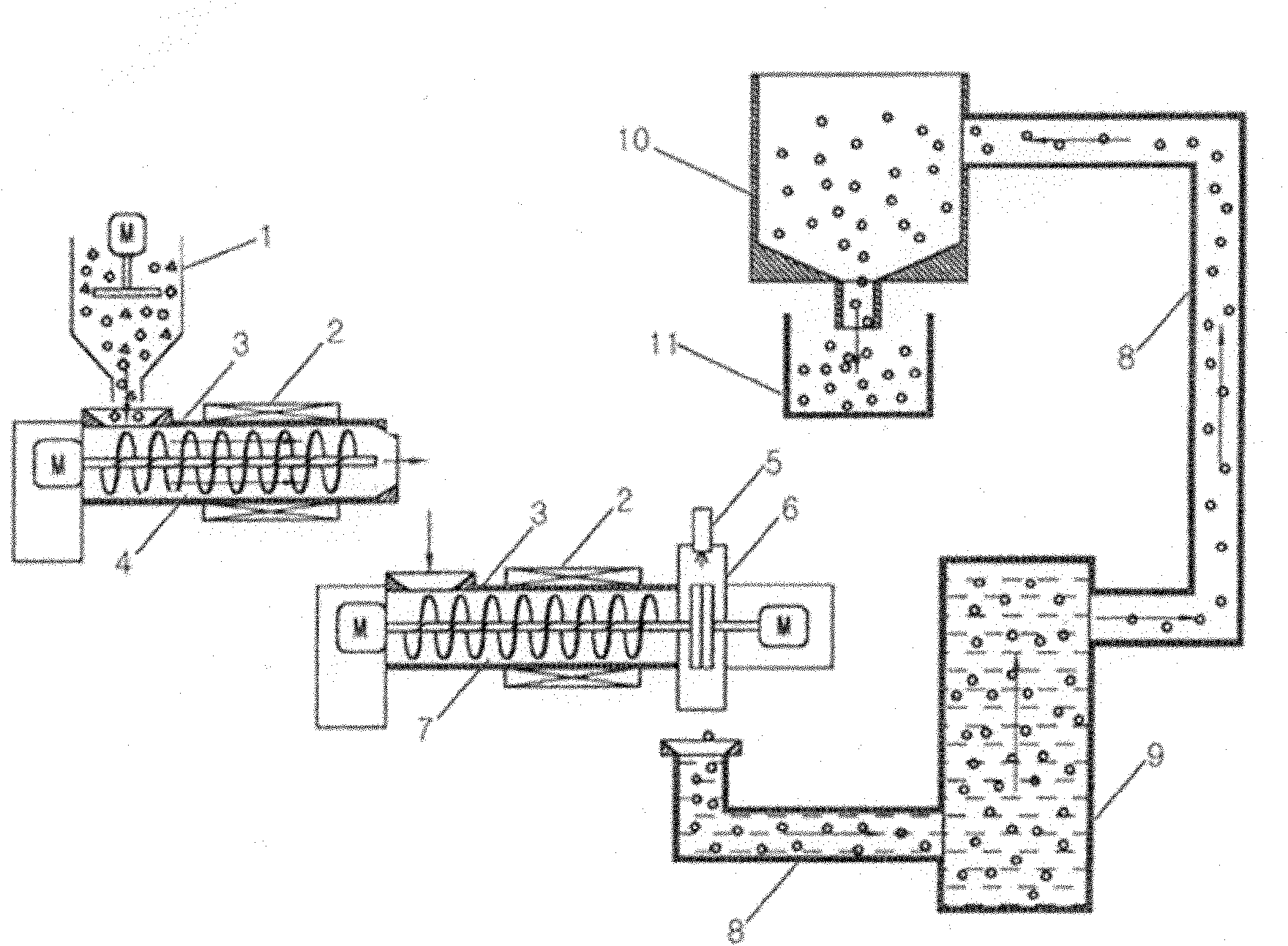

[0027] Embodiment 1: the preparation method of the granular carrier that is used for waste water treatment (the used device of preparation process sees figure 2 ): take by weight 60 parts of waste polyethylene, 20 parts of zeolite and 10 parts of powdered activated carbon and put them into the agitator 1, stir and mix for 30 minutes at a speed of 80 rpm, the mixture enters the melting extruder 4, and is heated Heater 2 is heated to 250°C at 0.2kgf / cm 2 Melt and extrude under pressure, and the melted and extruded mixture enters the extrusion molding machine 7, is heated to 280°C by the heater 2, and melts at 0.5kgf / cm 2 Press out the molding under the pressure, and then use the former 6 to cut it into a diameter of 5 ~ 10mm (if the diameter is less than 5mm, it is easy to block the micropores installed in the intermittent gas storm pool and the partition of the sediment, resulting in insufficient flow to the storm gas pool, and the gas storm There will be sludge overflowing f...

Embodiment 2

[0029] Embodiment 2: Take by weight 55 parts of waste polyethylene, 30 parts of zeolite and 15 parts of powdered activated carbon and put them into agitator 1, stir and mix at a speed of 75 rpm for 60 minutes, and the mixture enters the melting extruder 4, Heated to 200°C by heater 2, at 0.4kgf / cm 2 Melt and extrude under pressure, and the melted and extruded mixture enters the extruder 7, is heated to 230°C by the heater 2, and melts at 0.4kgf / cm 2 Extrude molding under the pressure of pressure, then cut into the granular shape of diameter 8mm with shaper 6. In order to increase the surface area of the carrier, water at 16° C. is sprayed from the water injector 5 during cutting to rapidly cool the formed carrier to prevent it from sticking to each other. Then the carrier mixed with water is transferred to the high-speed dehydrator 9 through the carrier delivery pipe 8, and the water is removed at a rotating speed of 1600rpm. The dehydrated carrier is transferred to the me...

Embodiment 3

[0031] Embodiment 3: take by weight 70 parts of waste polyethylene, 15 parts of zeolite and 5 parts of powdered activated carbon and put them into the agitator 1, stir and mix for 45 minutes at a speed of 78 rpm, and the mixture enters the melting extruder 4, Heated to 230°C by heater 2, at 0.3kgf / cm 2 It is melted and extruded under pressure, and the melted and extruded mixture enters the extrusion molding machine 7, is heated to 250°C by the heater 2, and melts at 0.3kgf / cm 2 Extrude molding under the pressure of pressure, then cut into the granular shape of diameter 10mm with shaper 6. In order to increase the surface area of the carrier, water at 14° C. is sprayed from the water injector 5 during cutting to rapidly cool the formed carrier to prevent it from sticking to each other. Then the carrier mixed with water is transferred to the high-speed dehydrator 9 through the carrier delivery pipe 8, and the water is removed at a rotating speed of 1550rpm. The dehydrated ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com