Conductor spacer framework for transmission line

A technology of power transmission lines and spacer bars, which is applied to devices for maintaining the distance between parallel conductors, etc., can solve the problems of many assembly processes, many spare parts, and high production costs, and achieve the effects of simple production process, increased mechanical strength, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

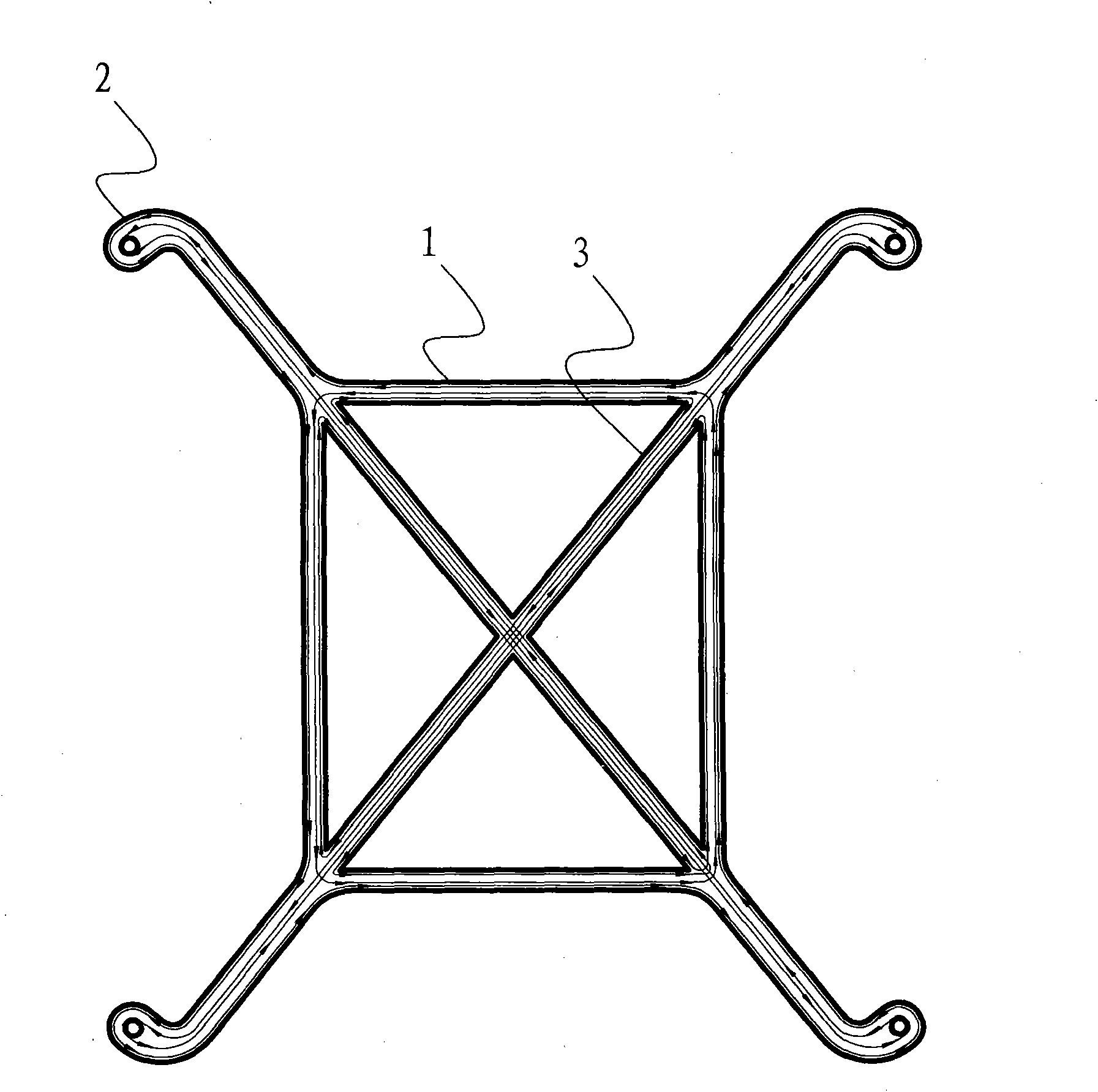

[0024] Such as figure 1 and figure 2 As shown, a spacer frame for transmission lines, including two-split, three-split, four-split, six-split, eight-split spacers, etc., taking the four-split spacer as an example, includes a body frame 1 and is integrally formed with the body frame 1 The wire clamp support arm 2 is integrally formed by the following components, 65% of the mixture, 35% of the fiber yarn, wherein the mixture consists of 30 parts of m-phenylene polyester resin, 10 parts of aluminum hydroxide, 10 parts of calcium carbonate, 10 parts of talcum powder, 10 parts of kaolin clay, 10 parts of silicon micropowder, 10 parts of glass powder, 5 parts of thinner acetone, 2 parts of pigment paste, 1 part of curing agent methyl ethyl ketone peroxide, 1 part of accelerator cobalt liquid, 1 part of ultraviolet absorber parts mixed.

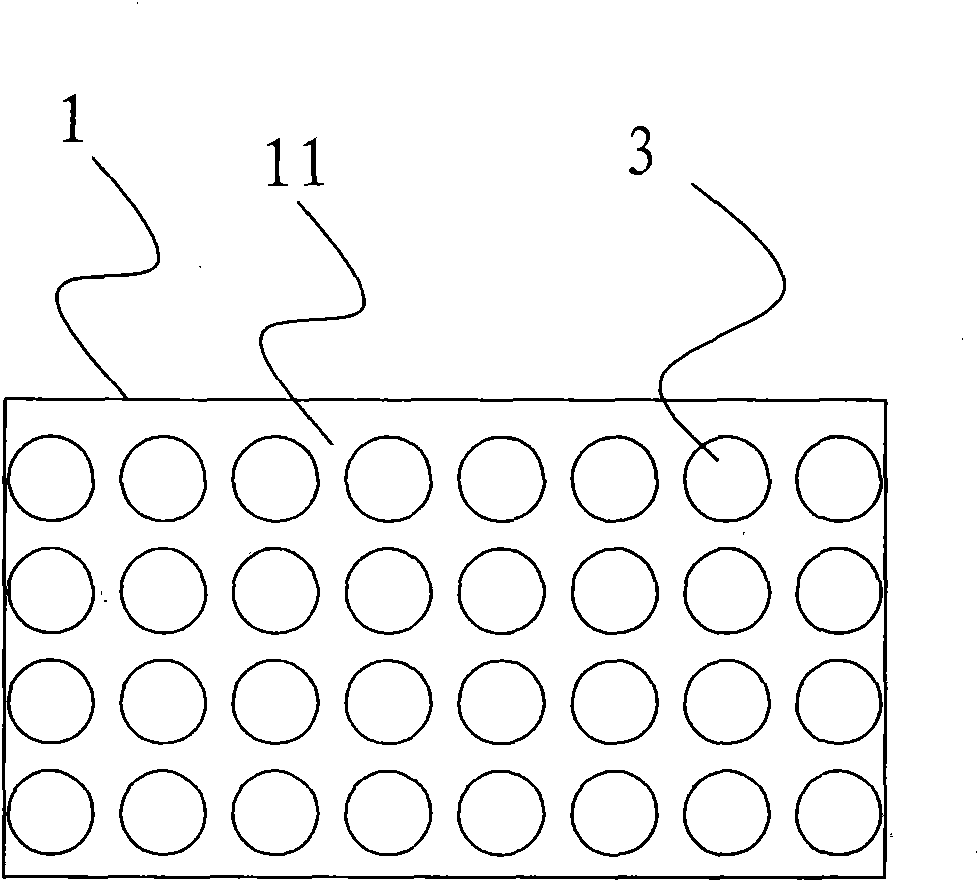

[0025] by figure 2 , image 3 and Figure 4 The shown spacer frame for transmission lines is taken as an example, including a body frame 1 a...

Embodiment 2

[0027] The rest are the same as in Example 1, except that it is integrally formed by the following components, 50% of the mixture and 50% of the fiber yarn, wherein the mixture consists of 25 parts of o-phthalic resin, 35 parts of diluent styrene, solidified It is prepared by mixing 2 parts of methyl ethyl ketone peroxide, 1 part of accelerator cobalt solution, and 37 parts of flame retardant aluminum hydroxide.

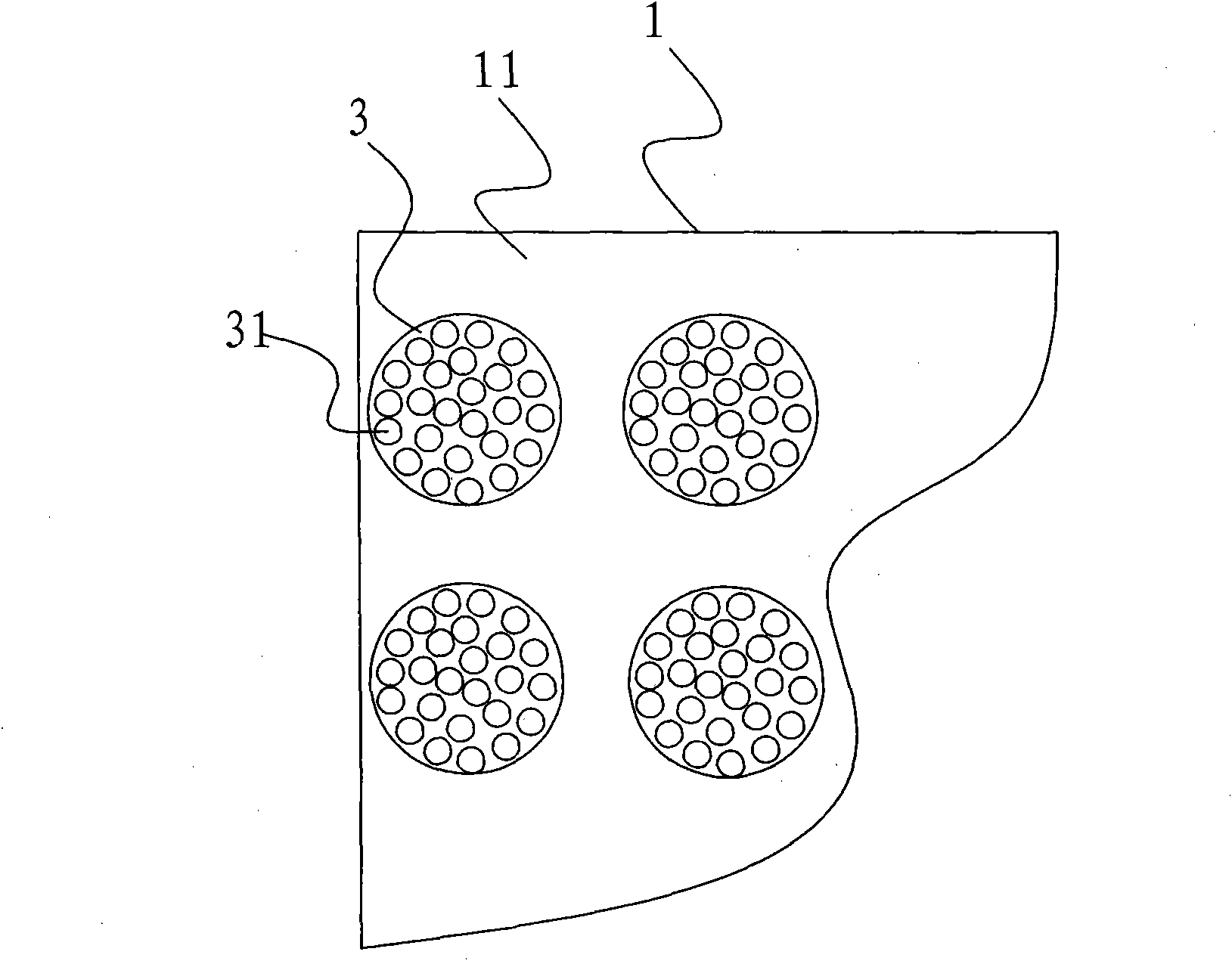

[0028] The fiber yarn of the present embodiment is used in the spacer frame of the power transmission line, and the specific way is as follows: Figure 4 , Figure 5 and Figure 6 As shown, the fiber yarn bundle 3 is continuously and reciprocally wound along the structural path of the body frame 1 and the clamp arm 2 . The winding direction of a part of the fiber yarn bundle 3 is circular winding along the shape of the body frame 1 and the clamp arm 2, and the other part of the fiber yarn bundle 3 is reciprocally cross-wound along the corresponding wire clamp arms,...

Embodiment 3

[0030] The rest are the same as in Example 1, except that the following components are integrally formed, 25% of the compound, 75% of the fiber yarn, wherein the compound consists of 99.7 parts of vinyl resin, curing agent dibenzoyl peroxide 0.3 part composition.

[0031] Wherein, the fiber yarn is continuous and is distributed in the spacer frame for power transmission line continuously, tautly and evenly along the path of the spacer frame frame for power transmission line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com