Non-curing adhesive waterproof material using recycled rubber, and manufacturing method thereof

A technology of recycled rubber and bonding materials, which is applied in the direction of recycled rubber adhesives, used vulcanized rubber adhesives, waste rubber adhesives, etc. It can solve the problem of only one-time processing and achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

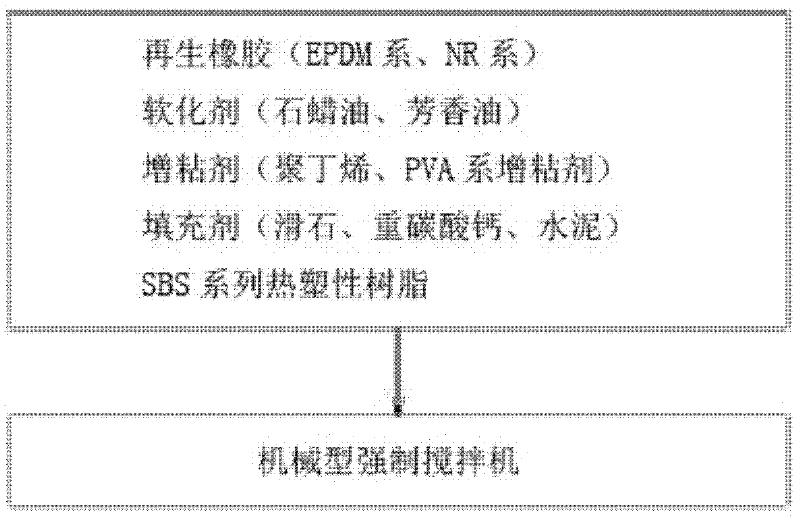

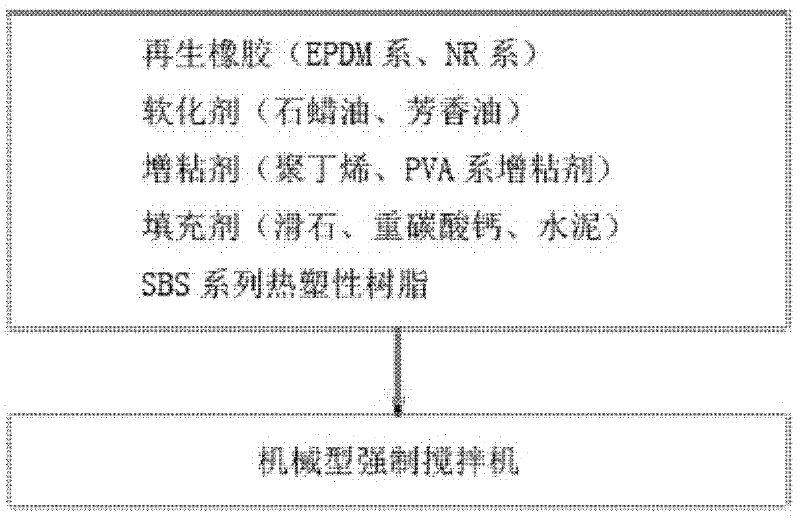

[0018] The present invention uses 18 to 28% by weight of recycled rubber (EPDM series, NR series), 6 to 15% by weight of softener (paraffin oil, aromatic oil), 14 to 24% by weight of tackifier (poly Butene, PVA-based tackifier), 40-60% by weight of filler (talc, bicarbonate, cement), 2 to 6% by weight of SBS-based thermoplastic resin, and forced mixing with a mechanical mixer.

[0019] In the following, the content of the implementation of the present invention will be described in detail and completely in combination with an example diagram of the implementation of the present invention.

[0020] According to the present invention, a non-vulcanized waterproof adhesive made of recycled rubber such as figure 1 As shown, 18~28% by weight of reclaimed rubber (EPDM series, NR series), 6~15% by weight of softener (paraffin oil, aromatic oil), 14~24% by weight of tackifier (poly Butene, PVA series tackifier), 40~60% by weight filler (talc, bicarbonate, cement), 2~6% by weight SBS series...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com