Method for preparing boron doped graphene

A technology of boron doping and graphene, applied in graphene, chemical instruments and methods, nano-carbon, etc., can solve problems such as high equipment requirements, difficult promotion, and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

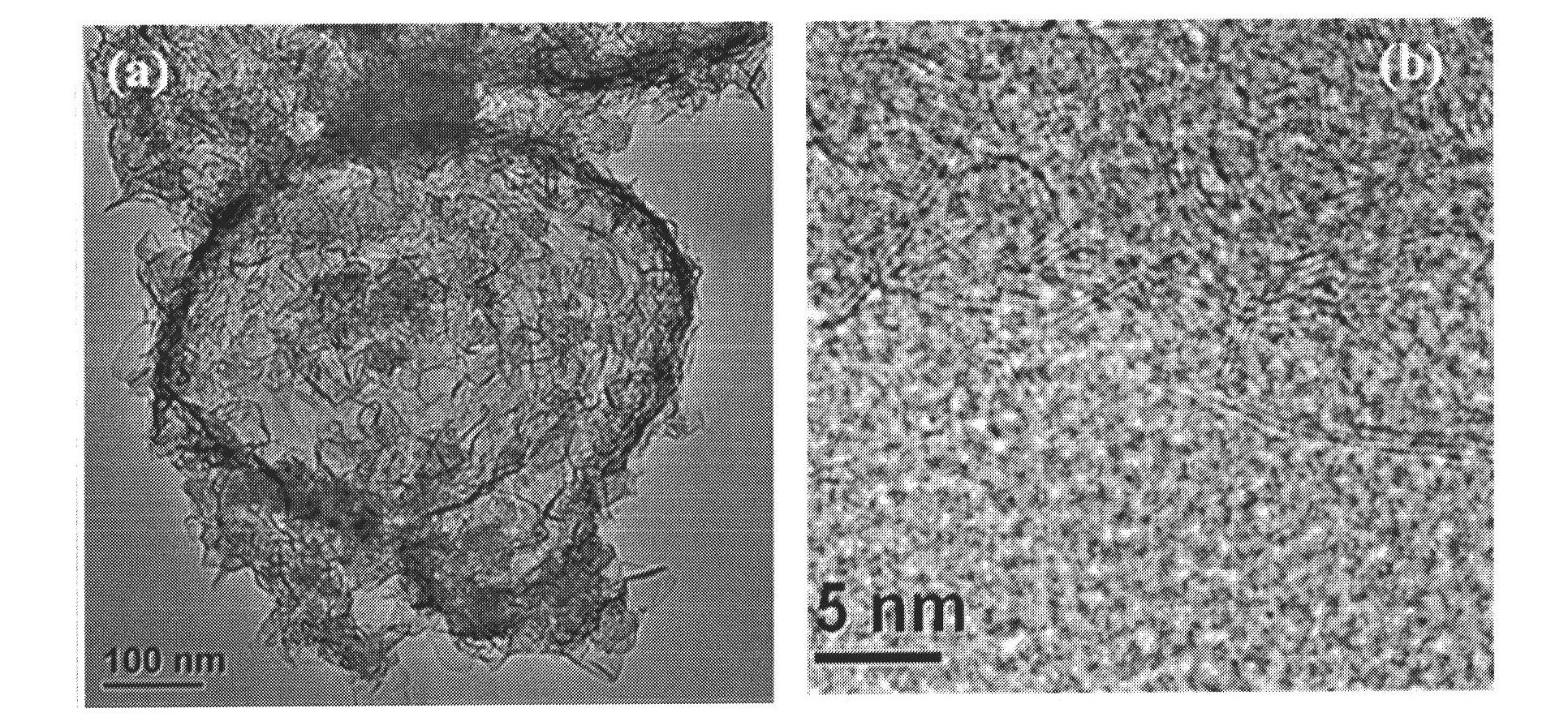

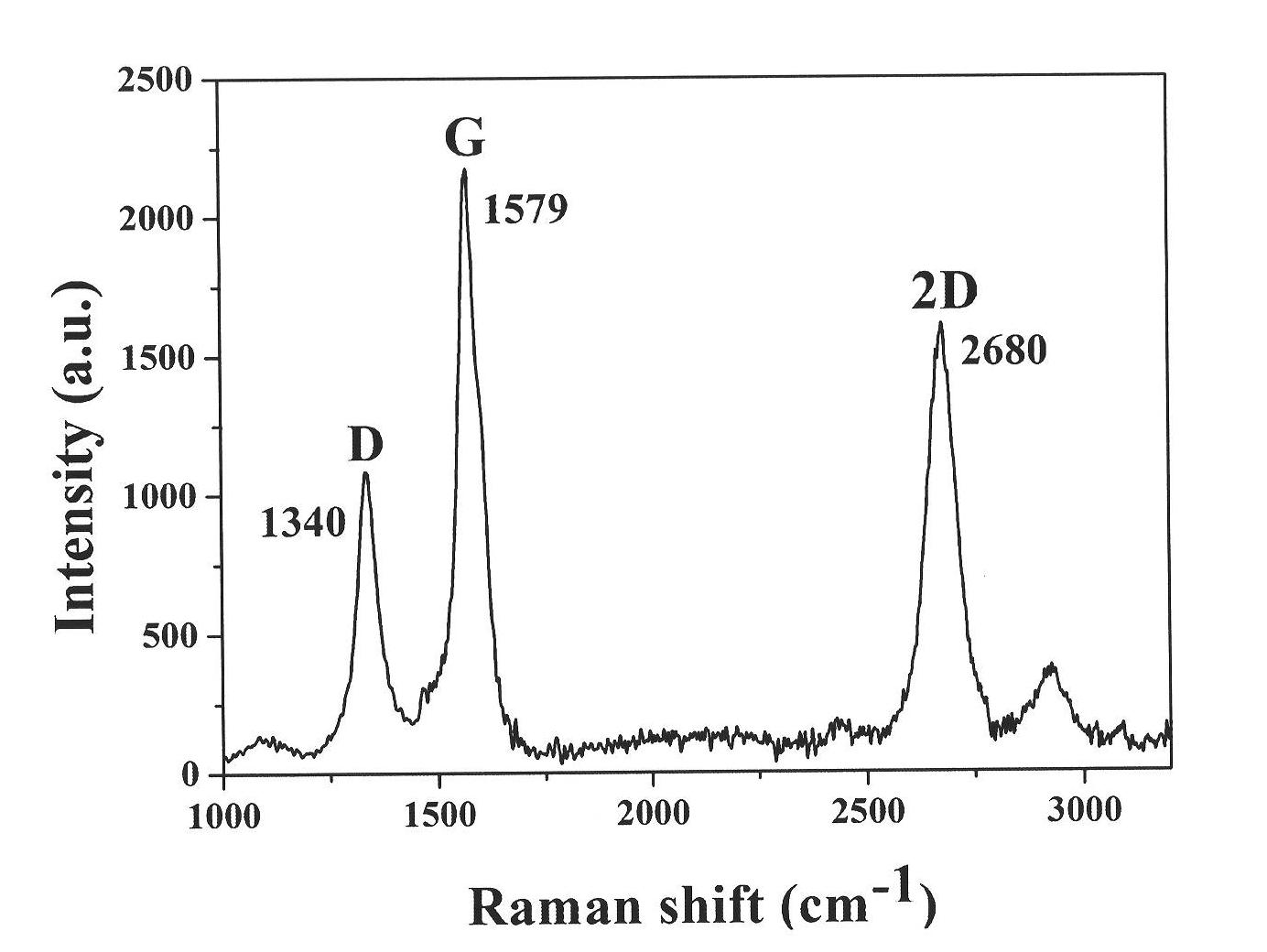

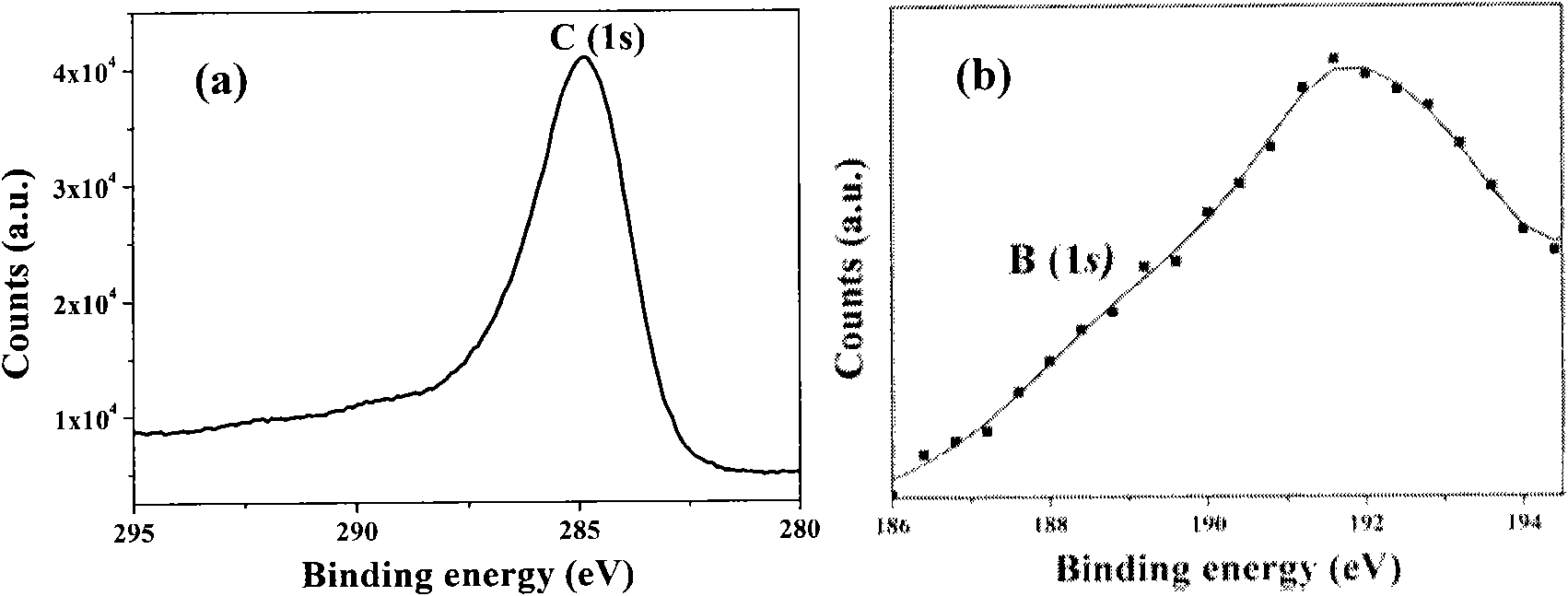

[0028] Synthesis of Boron-doped Graphene

[0029] Take out potassium metal in kerosene and put it into an anhydrous and oxygen-free glove box (containing H 2 O2 4 ) into a 30mL stainless steel reaction kettle with polytetrafluoroethylene lining, take 52 μL of boron tribromide (BBr 3 ) dissolved in carbon tetrachloride. Take 1.2g of potassium and put it into CCl 4 middle. Tighten the seal quickly afterwards. Put the reaction kettle into an oven, rapidly raise the temperature to 160°C within 60 minutes, and keep the temperature for 20 hours.

[0030] Purification of synthesized boron-doped graphene

[0031] After the reaction was over, it was naturally cooled to room temperature. Open the reaction kettle, add 100mL of absolute ethanol to the inner lining, wash out all the reaction products into a 200mL beaker, and stir thoroughly for 30min. filter. Wash the filter cake with deionized water, add 100mL of 10% hydrochloric acid solution, heat to 80°C, and fully stir for 30m...

Embodiment 2

[0037] Take 20 mL of benzene in the glove box and put it into a PTFE liner with a volume of 30 mL, add 60 μL of BBr 3 , add 4.0g of carbon tetrabromide (CBr 4 ), stirred thoroughly to dissolve. Take 2.0g of potassium and put it into the above solution, and place the lining in the stainless steel reaction kettle, and tighten the seal. Put the reaction kettle into an oven, rapidly raise the temperature to 180°C within 60 minutes, and keep the temperature for 12 hours.

[0038] The impurity removal purification and electrochemical performance testing process are as in Example 1.

Embodiment 3

[0040] Take 50 μL of BBr in the glove box 3 Dissolve it in 8mL of chloroform, put it into a polytetrafluoroethylene liner with a volume of 30mL, and put 2.0g of potassium into it. Place it in a stainless steel reaction kettle and tighten the seal. Put the reaction kettle into an oven, rapidly raise the temperature to 100°C within 60 minutes, and keep the temperature for 10 hours.

[0041] The impurity removal purification and electrochemical performance testing process are as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com