Method for applying diamond wire to mortar square cutting device

A diamond wire and equipment technology, which is applied in the field of diamond wire used in mortar cutting equipment, can solve problems such as broken wire, difficulty in maintaining a constant wire speed, and wire speed at the pay-off end less than the specified wire speed, etc., to achieve the elimination of environmental pollution and the advantages of large output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

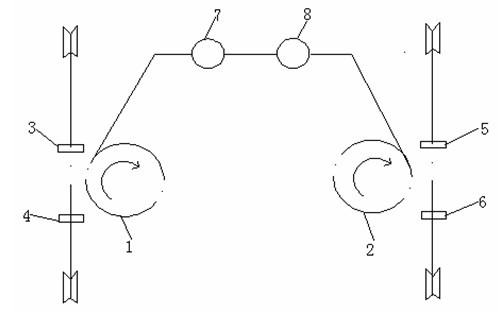

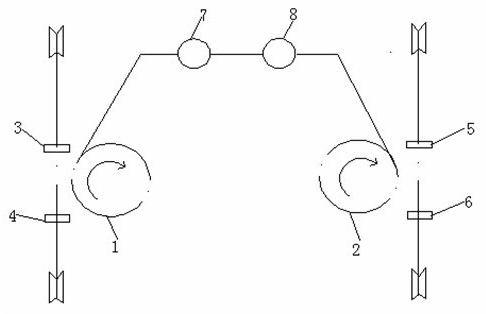

[0017] Such as figure 1 As shown, the diamond wire is used for mortar cutting equipment. The wire wheel part includes pay-off wheel 1 and take-up wheel 2. In this embodiment, a photoelectric sensor is installed on both sides of pay-off wheel 1 and take-up wheel 2, respectively. Install four photoelectric sensors to monitor the diameter of the wire wheel. The four photoelectric sensors are photoelectric sensor 3, photoelectric sensor 4, photoelectric sensor 5 and photoelectric sensor 6. The photoelectric sensor should be installed as close to the wire wheel as possible. The photoelectric sensor will transform the light signal sensed into an electrical signal, and display the monitored wire wheel diameter value on the display screen. So as to realize real-time monitoring and recording of the diameter of the diamond wire reel. The diamond wire discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com