Matte involucra coating adhesive for textile and preparation method thereof

A technology for textiles and coating adhesives, applied in textiles, papermaking, fiber processing, etc., can solve the problems of unpublished materials, affect usability, weak film feeling, etc., achieve good elasticity, increase stability, and soft vision. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

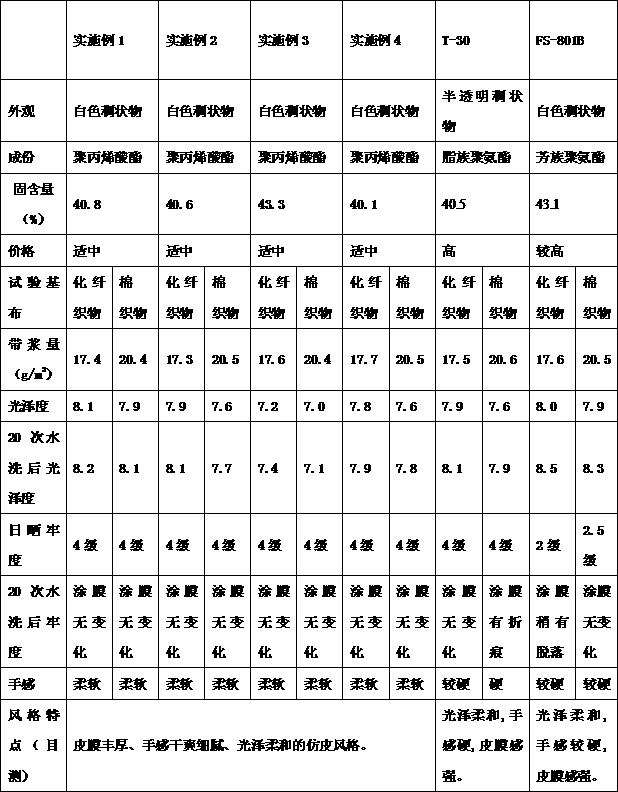

Examples

Embodiment 1

[0031] 1. Emulsion synthesis;

[0032] Pre-milk: In the pre-milk tank, mix 128 grams of deionized water, 2.5 grams of fatty alcohol polyoxyethylene ether, 1 sodium lauryl sulfate . 8 grams are fully mixed, while stirring, add 104 grams of ethyl acrylate, 26 grams of isooctyl methacrylate, 1-2-hydroxyethyl methacrylate . 9 g, N-methylolacrylamide 3 . 9 grams, triethylene glycol dimethacrylate 1.5 grams, styrene 34 grams, acrylic acid 4 . 5 grams to obtain a pre-emulsion;

[0033] Initiate the polymerization reaction: 0.48 grams of initiator ammonium persulfate and 0.48 grams of sodium bisulfite are dissolved in 10 grams of deionized water respectively. 25% of the pre-emulsion is used as the seed emulsion, add 40% of the initiator solution at 45-50°C, react for 30-40 minutes, control the temperature at 70-75°C, then add the remaining pre-emulsion dropwise, and at the same time add the remaining Initiator solution, the dripping time is 3-3.5 hours to complete, after the dropp...

Embodiment 2

[0037] 1. Emulsion synthesis;

[0038] Pre-milk: In the pre-milk tank, mix 135 grams of deionized water, 2.3 grams of fatty alcohol polyoxyethylene ether, 1 sodium lauryl sulfate . 6 grams are fully mixed, while stirring, add 101 grams of ethyl acrylate, 28 grams of isooctyl methacrylate, 2-hydroxyethyl methacrylate . 0 g, N-methylolacrylamide 3 . 6 grams, triethylene glycol dimethacrylate 1.8 grams, styrene 33 grams, acrylic acid 4 . 0 g, to obtain a pre-emulsion;

[0039] Initiate the polymerization reaction: 0.43 grams of initiator ammonium persulfate and 0.43 grams of sodium bisulfite are dissolved in 8 grams of deionized water respectively. 25% of the pre-emulsion is used as the seed emulsion, add 40% of the initiator solution at 45-50°C, react for 30-40 minutes, control the temperature at 70-75°C, then add the remaining pre-emulsion dropwise, and at the same time add the remaining Initiator solution, the dripping time is 3-3.5 hours to complete, after the dripping, t...

Embodiment 3

[0043] 1. Emulsion synthesis;

[0044] Pre-milk: In the pre-milk tank, mix 117 grams of deionized water, 2.4 grams of fatty alcohol polyoxyethylene ether, sodium lauryl sulfate 2 . 0 g and mix well, while stirring, add 105 g of ethyl acrylate, 25 g of isooctyl methacrylate, 1-2-hydroxyethyl methacrylate . 8 g, N-methylolacrylamide 3 . 5 grams, 1.9 grams of triethylene glycol dimethacrylate, 34 grams of styrene, and 4.1 grams of acrylic acid obtain a pre-emulsion;

[0045] Initiate the polymerization reaction: 0.41 grams of initiator ammonium persulfate and 0.41 grams of sodium bisulfite are dissolved in 10 grams of deionized water respectively. 25% of the pre-emulsion is used as the seed emulsion, add 40% of the initiator solution at 45-50°C, react for 30-40 minutes, control the temperature at 70-75°C, then add the remaining pre-emulsion dropwise, and at the same time add the remaining Initiator solution, the dripping time is 3-3.5 hours to complete, after the dropping, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com