Boiler for producing steam by combusting SiC crystals and method for producing steam

A technology of crystal production and steam, applied in combustion methods, steam boilers, combustion equipment, etc., can solve problems such as environmental pollution and adverse effects on plant growth, and achieve the effects of solving environmental pollution problems, avoiding over-exploitation, and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

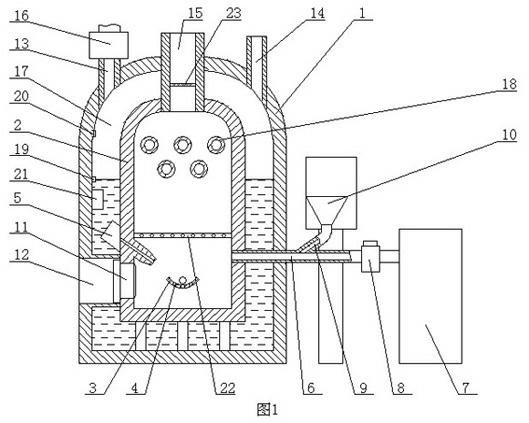

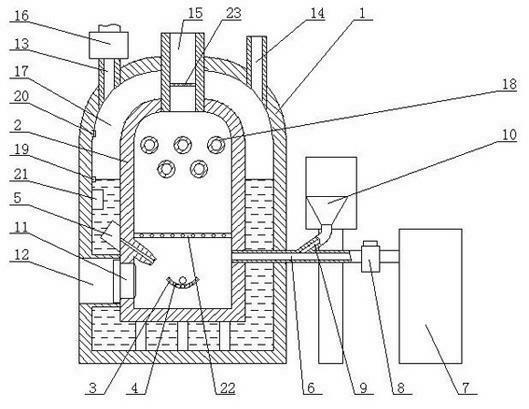

[0013] The boiler for producing steam by burning SiC crystals according to the present invention includes a casing 1, a water storage cavity 17 is formed in the casing 1, a water supply pipe 13 and a steam pipe 14 are arranged on the top of the casing 1, and a water supply pump is installed on the water supply pipe 13 16. A combustion chamber 2 is installed in the water storage cavity 17, an exhaust pipe 15 is set on the top of the combustion chamber 2, an arc tray 3 is set in the combustion chamber 2, a through hole 4 is provided on the arc tray 3, and a laser is installed on the side wall of the combustion chamber 2 Source 5 and oxygen supply pipe 6, oxygen supply pipe 6 is connected with oxygen station 7, oxygen supply pipe 6 is equipped with booster pump 8 and feed branch pipe 9, feed branch pipe 9 is connected with the discharge port of powder metering filling machine 10, A cleaning door 11 is provided in the lower part of the combustion chamber 2, and the cleaning door 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com