Boiler cleaning process

A boiler cleaning and boiler technology, applied to boiler cleaning devices, etc., can solve the problems of easy acid corrosion, hidden dangers of boiler safe operation, inconvenient on-site application, etc., achieve considerable economic and environmental benefits, reduce the consumption of chemical agents, improve The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

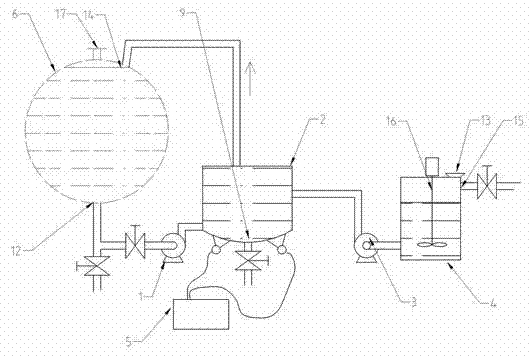

[0033] A method for boiler cleaning, comprising the following steps:

[0034] ① Establish a cleaning pump station

[0035] Set up a cleaning circulation pump (1) and a cleaning liquid treatment tank (2) between the sewage outlet (12) and the water inlet (14) of the boiler system (6); connect the water injection pump (3) and the water supply tank (4), Isolation and cleaning have nothing to do with the system, including the valves connected to the boiler system and pipelines within the cleaning range must be closed tightly, the devices and cyclone separators in the steam drum that are not suitable for cleaning must be removed, and the water level gauge and all instruments must be removed;

[0036] ②Hot pressure test

[0037] Fill the steam drum of the boiler system (6) with water through the water injection pump (3) and the water supply tank (4), close the water injection pump (3) and the exhaust port (17) of the boiler system, and start the cycle of the cleaning circulation pu...

Embodiment 2

[0047] A method for boiler cleaning, comprising the following steps:

[0048] ① Establish a cleaning pump station

[0049] Set up a cleaning circulation pump (1) and a cleaning liquid treatment tank (2) between the sewage outlet (12) and the water inlet (14) of the boiler system (6); connect the water injection pump (3) and the water supply tank (4), Isolation and cleaning have nothing to do with the system, including the valves connected to the boiler system and pipelines within the cleaning range must be closed tightly, the devices and cyclone separators in the steam drum that are not suitable for cleaning must be removed, and the water level gauge and all instruments must be removed;

[0050] ②Hot pressure test

[0051] Fill the steam drum of the boiler system (6) with water through the water injection pump (3) and the water supply tank (4), close the water injection pump (3) and the exhaust port (17) of the boiler system, and start the cycle of the cleaning circulation pu...

Embodiment 3

[0061] A method for boiler cleaning, comprising the following steps:

[0062] ① Establish a cleaning pump station

[0063] Set up a cleaning circulation pump (1) and a cleaning liquid treatment tank (2) between the sewage outlet (12) and the water inlet (14) of the boiler system (6); connect the water injection pump (3) and the water supply tank (4), Isolation and cleaning have nothing to do with the system, including the valves connected to the boiler system and pipelines within the cleaning range must be closed tightly, the devices and cyclone separators in the steam drum that are not suitable for cleaning must be removed, and the water level gauge and all instruments must be removed;

[0064] ②Hot pressure test

[0065] Fill the steam drum of the boiler system (6) with water through the water injection pump (3) and the water supply tank (4), close the water injection pump (3) and the exhaust port (17) of the boiler system, and start the cycle of the cleaning circulation pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com