Copper electrode alumina ceramic substrate used in large power LED

A technology of alumina ceramics and copper electrodes, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of unsuitable aluminum nitride substrates, fragmentation, and insufficient strength of anodized oxide layers, and achieves simple preparation processes and thermal conductivity. High coefficient and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

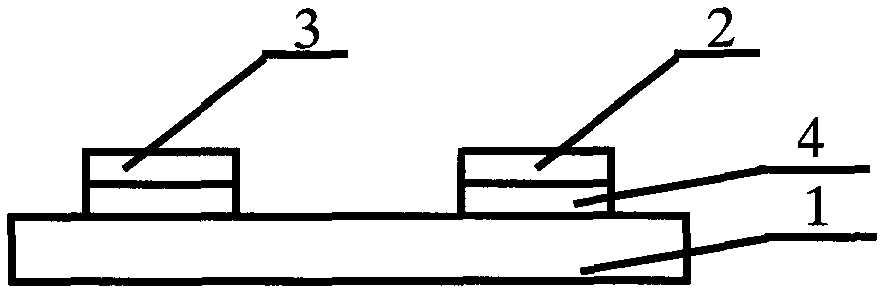

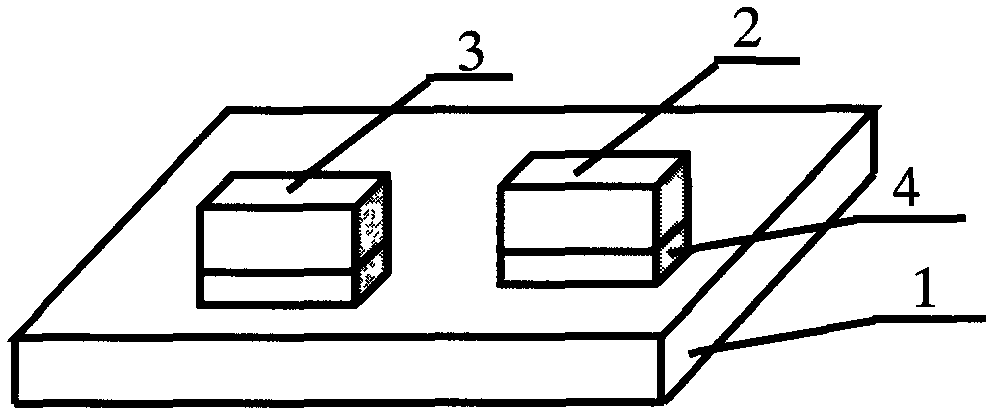

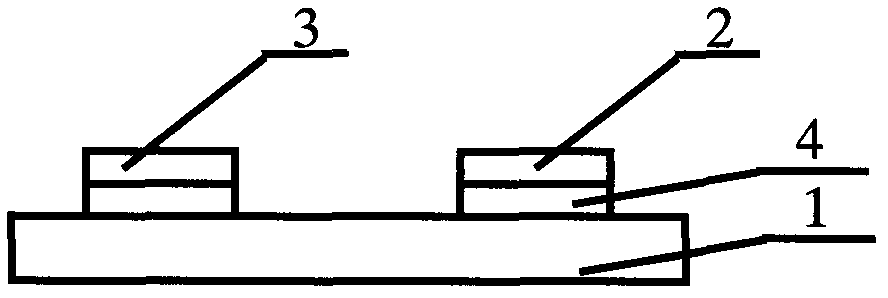

[0023] Implementation example 1: such as figure 1 and figure 2 As shown, a copper electrode aluminum oxide ceramic substrate for high-power LED is characterized in that: it is modified by aluminum oxide layer (1), first copper electrode (2), second copper electrode (3) and copper aluminum oxide layer (4) composition; aluminum oxide layer (1) is deposited on the copper aluminum oxide modified layer (4), on the copper aluminum oxide modified layer (4) is the first copper electrode (2) and the second copper electrode ( 3); the separation distance between the first copper electrode (2) and the second copper electrode (3) is 1mm.

[0024] A copper electrode aluminum oxide ceramic substrate for high-power LEDs, comprising the following preparation steps:

[0025] ① Weigh the reagent (gibbsite (Al 2 o 3 ·3H 2 O) account for 60% bauxite and sodium hydroxide (purity 99.99%)), these components are fully mixed, let stand for 4 hours, and filter;

[0026] ②Put the above-mentioned f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com