Method for preparing novel silver ion molecular sieve as antiseptic

A molecular sieve, silver ion technology, applied in the fields of botanical equipment and methods, molecular sieves and alkali exchange compounds, paints containing biocides, etc., can solve the problems of poor antibacterial effect and durability, poor dispersibility and compatibility of antibacterial materials, etc. To solve the effect of poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

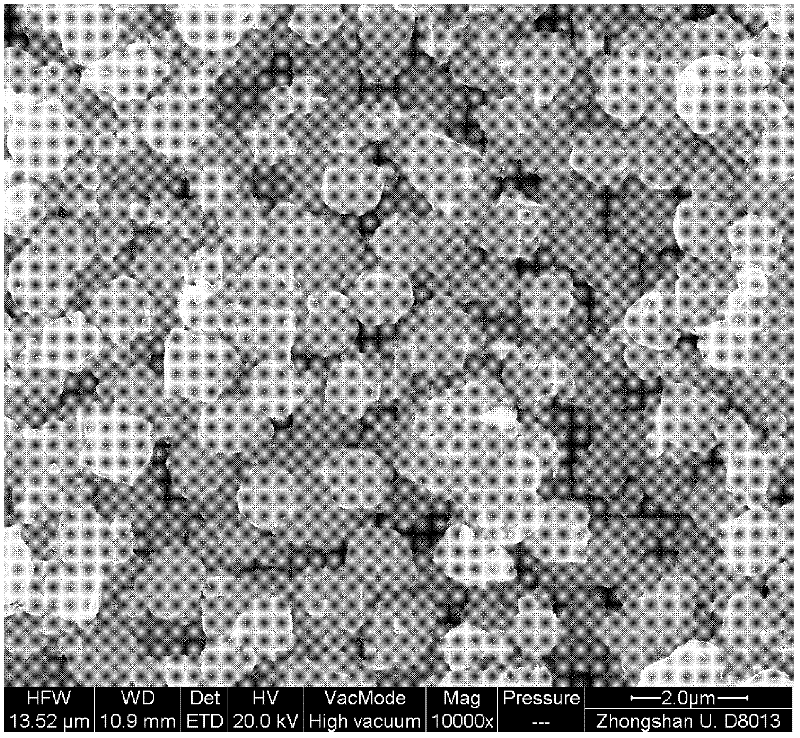

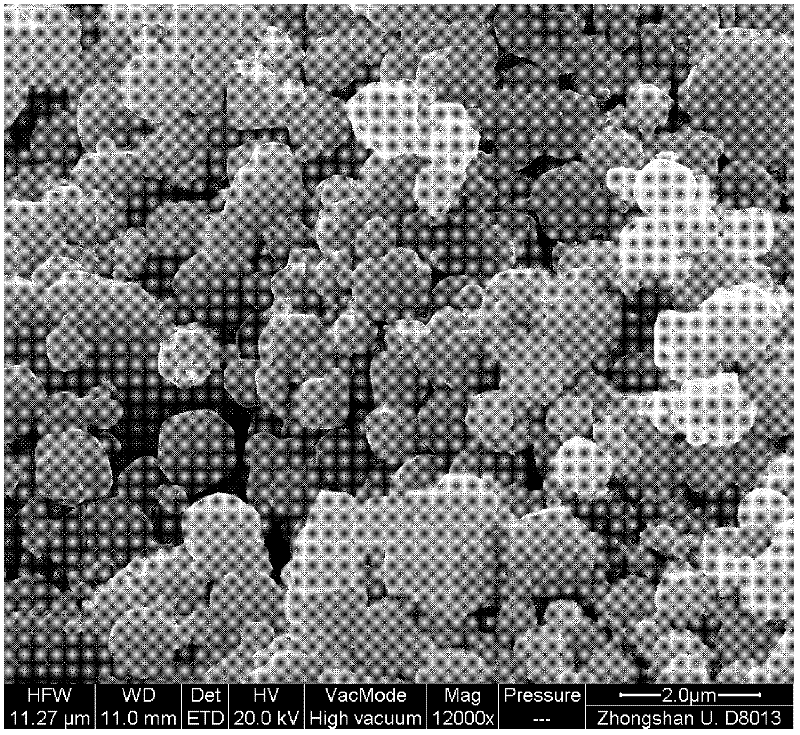

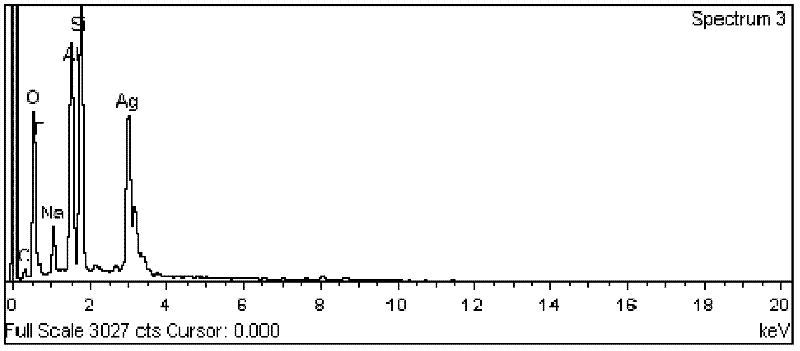

[0022] The preparation process of novel silver ion molecular sieve antibacterial agent of the present invention, used raw material comprises aluminum source, silicon source, alkali, templating agent and water, adopts hydrothermal synthesis method, comprises following two steps:

[0023] (1) Preparation of molecular sieves with controllable particle size: the molar ratio of raw materials silicon source, aluminum source, templating agent, alkali and water is: Si / Al=0.5~15; OH - / Si=0.05~1; Template / SiO 2 =0.05~3;H 2 O / SiO 2 = 10-100, mixed and stirred to obtain a mixed solution, the mixed solution was subjected to hydrothermal synthesis at 60-200°C, and the solid product was taken out after 6-240 hours, washed with water and dried to obtain a crude molecular sieve product; the above-mentioned crude product 0.01-0.1M NaOH / H 2 O (heat treatment of dilute lye) heat treatment reaction at 50°C for 5 days to remove impurities on the surface, filter, and dry at 50-150°C under normal...

Embodiment 1

[0027] The first step: Molecular sieve preparation

[0028] 1. Take 2g of water, then add 2.25g of silicon source (Ludox SM-30, silica sol), and start stirring;

[0029] 2. Take 5.75g of water, add 5g of TMAOH (tetramethylammonium hydroxide) (25wt%), then add 0.75g of aluminum source (AIP, aluminum isopropoxide), stir slightly until it is completely dissolved;

[0030] 3. Take 1.62g of NaOH, dissolve it in 10g of water, stir evenly, take out 1.162g of the aqueous solution, and add it dropwise to the solution obtained in step 2 while stirring continuously;

[0031] 4. Slowly add the mixture obtained in step 1 into the solution obtained in step 3, stirring continuously for 24 hours;

[0032] 5. Put the synthesis solution obtained in the above step 4 into the reactor, and react at 100°C for 2 days;

[0033] 6. The final synthesized product is subjected to dilute lye (0.01-0.1M NaOH / H 2 (0) heat treatment (reaction for 5 days at 50° C.), to remove amorphous impurities present o...

Embodiment 2

[0041] A preparation method of a silver ion molecular sieve antibacterial agent. In this embodiment, except that the proportion of the reaction solution is: 3.75g silica sol: 5g TMAOH: 0.75g aluminum isopropoxide: 0.162gNaOH, the others are the same as in Example 1 to obtain silver ions Molecular sieve antibacterial agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com