Method for bottling and fermenting chopped hot peppers

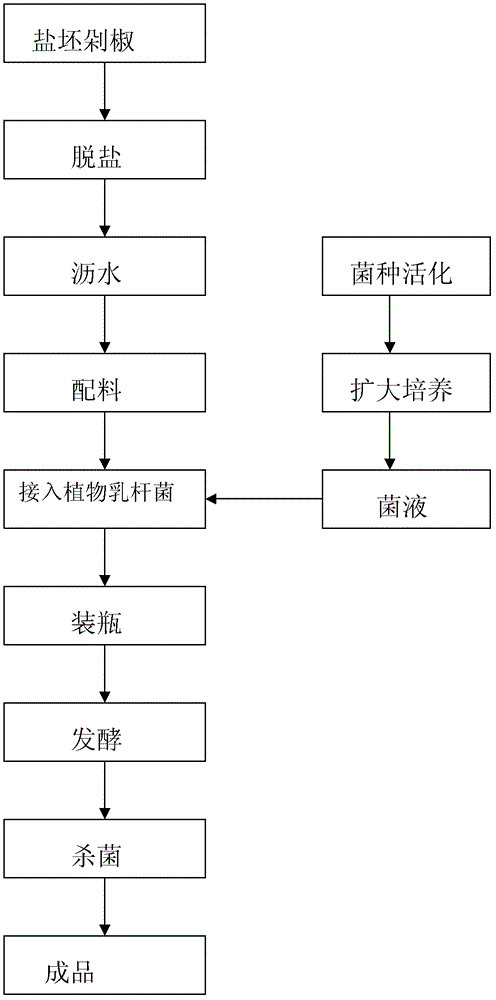

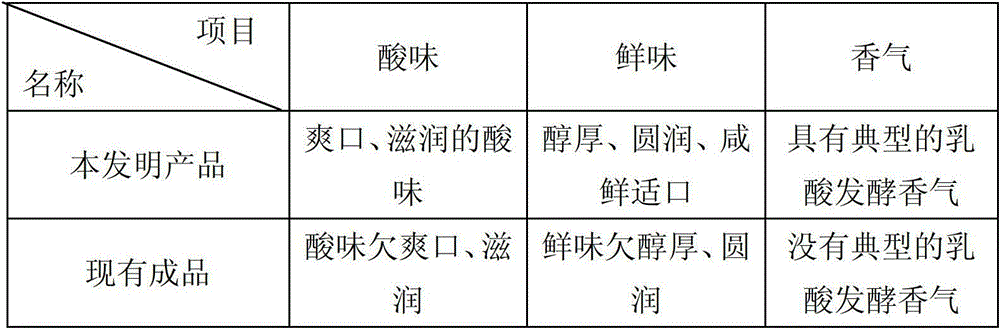

A technology for bottling fermentation and chopping peppers, which is applied in applications, food preparation, food science, etc. It can solve the problems of microbial fermentation, no fermentation aroma, and long fermentation time, so as to reduce the accumulation of nitrite and increase the aroma of fermentation. , the effect of short fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 100 kg of salted chili peppers, soak the salted chili peppers with the same volume of water as the salted chili peppers for 60 minutes to desalinate the salted chili peppers, so that the salt content of the salted chili peppers is reduced to about 8%; Add 0.4kg of monosodium glutamate, 3kg of garlic, 0.4kg of white wine with an alcohol content of more than 50 degrees, 2kg of sucrose, 0.04kg of calcium chloride, and 0.04kg of potassium sorbate to the drained salt and chopped peppers, And mix well to form the initial product of chopped pepper; mix in the number of live bacteria to reach 10 8 3 kg of Lactobacillus plantarum liquid above cfu / mL, mixed well, put into a packaging bottle for market circulation, and fermented at 25°C for 50 hours; Sterilize for 15 minutes to form a finished product.

Embodiment 2

[0026] Embodiment 2: Get 100kg of salt base pepper, soak the salt base chopped pepper with the same volume of the salt base chopped pepper for 45 minutes and carry out desalination treatment, so that the salt content of salt base pepper is reduced to about 10%; the salt after desalination Take out the chopped peppers and drain the water; add 0.5kg of monosodium glutamate, 4kg of garlic, 0.5kg of white wine with an alcohol content of more than 50 degrees, 3kg of sucrose, 0.05kg of calcium chloride, and sorbic acid to the drained salt and chopped peppers. Potassium 0.05kg, and mix well to form the initial product of chopped pepper; mix in the number of live bacteria to reach 10 8 4kg of Lactobacillus plantarum liquid above cfu / mL, mixed well, put into a packaging bottle for market circulation, and fermented at 30°C for 48h; Sterilize for 12 minutes to form a finished product.

Embodiment 3

[0027] Embodiment 3: get salt base pepper 100kg, soak salt base chopped pepper with the water equal volume of this salt base chopped pepper for 30 minutes and carry out desalination treatment, the salt content of salt base pepper is reduced to about 12%; Take out the chopped peppers and drain the water; add 0.6kg of monosodium glutamate, 5kg of garlic, 0.6kg of white wine with an alcohol content of more than 50 degrees, 4kg of sucrose, 0.06kg of calcium chloride, and sorbic acid to the drained salt and chopped peppers. Potassium 0.06kg, and mix well to form the initial product of chopped pepper; mix in the number of live bacteria to reach 10 8 5 kg of Lactobacillus plantarum liquid above cfu / mL, mixed well, put into a packaging bottle for market circulation, and fermented at 35°C for 46 hours; Sterilize for 10 minutes to form a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com