Microfluidic chip capable of being used for enzyme-linked immunoassay

An ELISA and microfluidic chip technology, which is applied to laboratory containers, chemical instruments and methods, laboratory utensils, etc., can solve the problems of high background value, expensive, complex ELISA equipment, etc., and achieve low consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

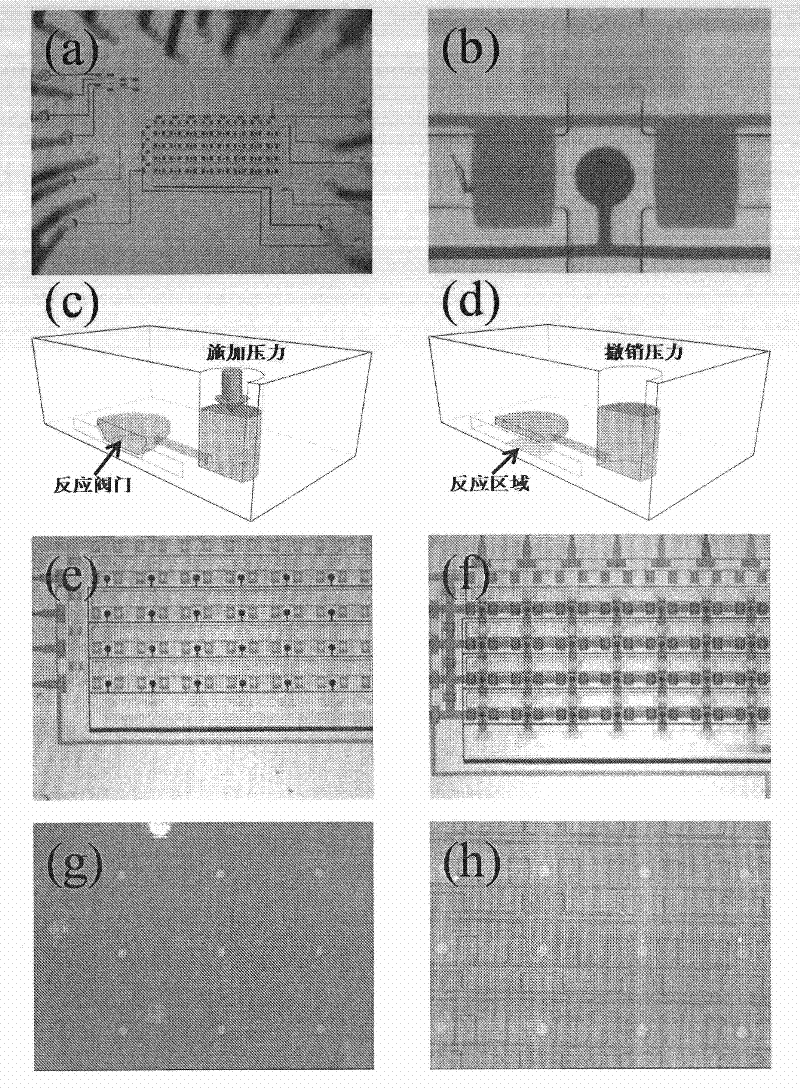

[0029] The following examples illustrate the preparation method of microfluidic chips. In the following examples, relatively simple photoresist SU-8, AZP 4620 and PDMS (Sylgard 184) are used to prepare, but it does not mean that microfluidic chips can only be prepared by this method. Those skilled in the art can understand that any existing technology in the art can be used to prepare the microfluidic chip with the structure of the present invention.

[0030] We first use the method of photolithography to make the templates of the fluid layer pipeline (ie, the microfluidic channel) and the control layer pipeline (ie, the control channel). The control layer pipeline is made of negative glue SU8-2010. Pour negative glue SU8-2010 onto a clean silicon wafer, rotate at 1000rpm for 1 minute, bake on a heating plate at 65 degrees for 5 minutes, bake on a heating plate at 95 degrees for 10 minutes, expose, repeat baking on a heating plate at 65 degrees for 5 minutes, Bake on a heatin...

Embodiment 1

[0033] Structure of the microfluidic chip. This embodiment describes in detail a preferred structure of the microfluidic chip of the present invention, the structure is as figure 1 shown. The microfluidic layer of the chip has 4 horizontal microfluidic channels and 8 vertical microfluidic channels, which intersect with each other to form a 4×8 checkerboard matrix. The 32 reaction valves at the 32 intersections correspond to 32 ELISA At the reaction site, there are four control valves around each reaction valve, which control the four-direction microfluidic channels connected to the reaction site. On the horizontal microfluidic channel, a set of 2 control valves to form a smaller closed reaction space around the reaction site perimeter, so there are 80 such control valves in total. The microfluidic channel communicates with the external connection through several pipes, some of which are used to inject liquid into the microfluidic channel, and the rest of the pipes are used t...

Embodiment 2

[0035] The specific test operation process.

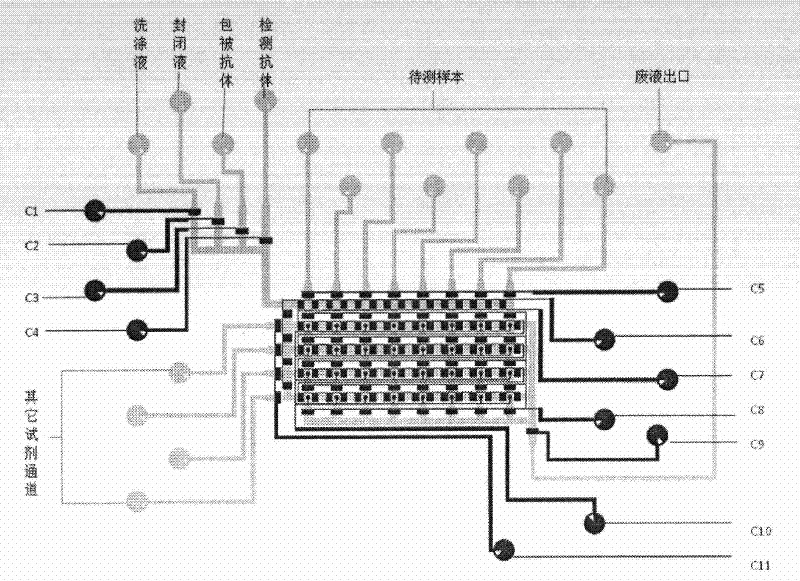

[0036] figure 2 A schematic of the microfluidic chip design is shown. The operation process of the ELISA test will be described in detail below in conjunction with the chip design diagram.

[0037] Chip structure such as figure 2 shown. In the actual microfluidic chip immunoassay, 11 valves (corresponding to figure 2 C1-C11) control the injection of different reagents, as well as the flow direction of the liquid. The round black valves are reaction valves and the rectangular black valves are control valves. The functions of C1-C11 valves are as follows: C1, C2, C3, and C4 valves respectively control the injection of washing liquid (PBS), blocking buffer (Blocking Buffer), coating antibody (CapAb), and detection antibody (DetAb); C5 valve Control the injection of eight gradient parallel channels (sample to be tested); C6 valve protects the entire chip; C7 valve controls the flow of liquid along the longitudinal parallel pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com