Sn-Ag-Cu-Bi-Er low-silver and lead-free welding flux and preparation method for same

A sn-ag-cu-bi-er, lead-free solder technology, used in welding equipment, welding/cutting media/materials, welding media, etc., can solve the adverse effects of post-weld mechanical properties, low alloy fatigue resistance, melting process increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

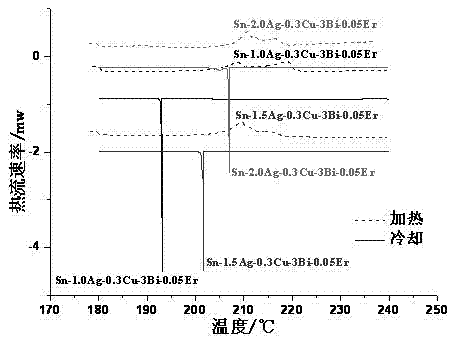

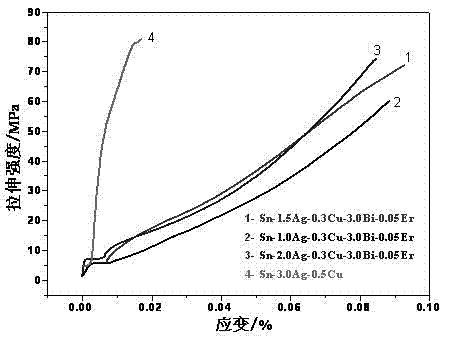

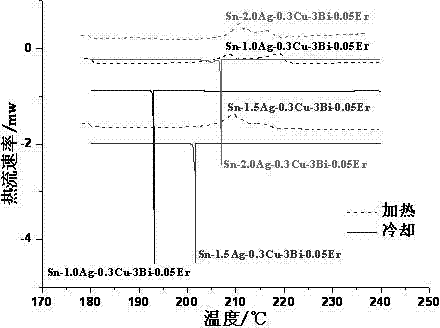

[0017] Example 1 Preparation of Sn-1.5Ag-0.3Cu-3.0Bi-0.05Er

[0018] According to the proportion by weight of each component, Ag is 1.5%, Cu is 0.3%, Bi is 3.0%, Er is 0.05%, and the balance is Sn.

[0019] The preparation process is as follows: prepare 50g of Sn-10Er master alloy according to the weight ratio in a vacuum electric arc melting furnace; mix the weighed pure Sn and Er, heat to 1600°C in a vacuum electric arc furnace, stir and melt, keep warm for 30min and then cool , repeated smelting 3 times to make button ingots. Weigh 0.5g of Sn-10Er master alloy, 1.5g of Ag, 0.3g of Cu, 3.0g of Bi and 94.7g of Sn; after fully mixing, place it in a vacuum induction melting furnace for high-temperature melting at 900°C and keep it warm for 30 minutes to ensure that the obtained alloy The uniformity of the composition; the resulting solder alloy was vacuum remelted at a temperature of 300 °C,

[0020] Keep it warm for 1 hour, and then cool it in air to prepare a solder ingot f...

Embodiment 2

[0021] Example 2 Preparation of Sn-1.0Ag-0.3Cu-3.0Bi-0.05Er

[0022] According to the proportion by weight of each component, Ag is 1.0%, Cu is 0.3%, Bi is 3.0%, Er is 0.05%, and the balance is Sn.

[0023] Its preparation method is the same as embodiment 1.

[0024]

Embodiment 3

[0025] Example 3 Preparation of Sn-2.0Ag-0.3Cu-3.0Bi-0.05Er

[0026] According to the proportion by weight of each component, Ag is 2.0%, Cu is 0.3%, Bi is 3.0%, Er is 0.05%, and the balance is Sn.

[0027] Its preparation method is the same as embodiment 1.

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com