Unit module for constructing stacked structure type low-temperature plasma reaction body

A low-temperature plasma, unit module technology, applied in the field of discharge unit modular structure and unit module, can solve problems such as difficulty in obtaining heat dissipation effect, difficulty in stable control, and complex conditions, so as to improve ozone synthesis efficiency, improve work efficiency, and improve The effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

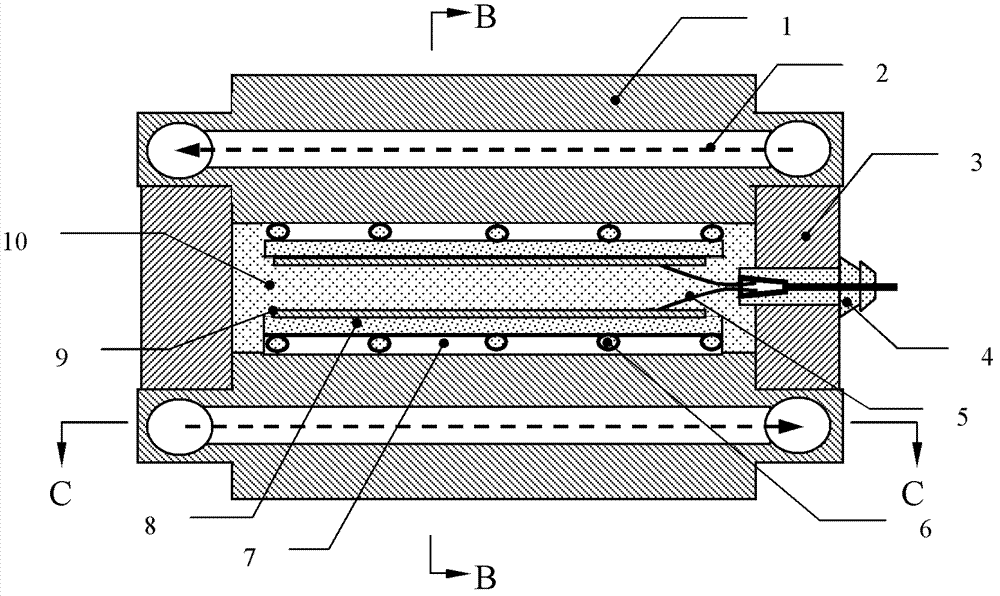

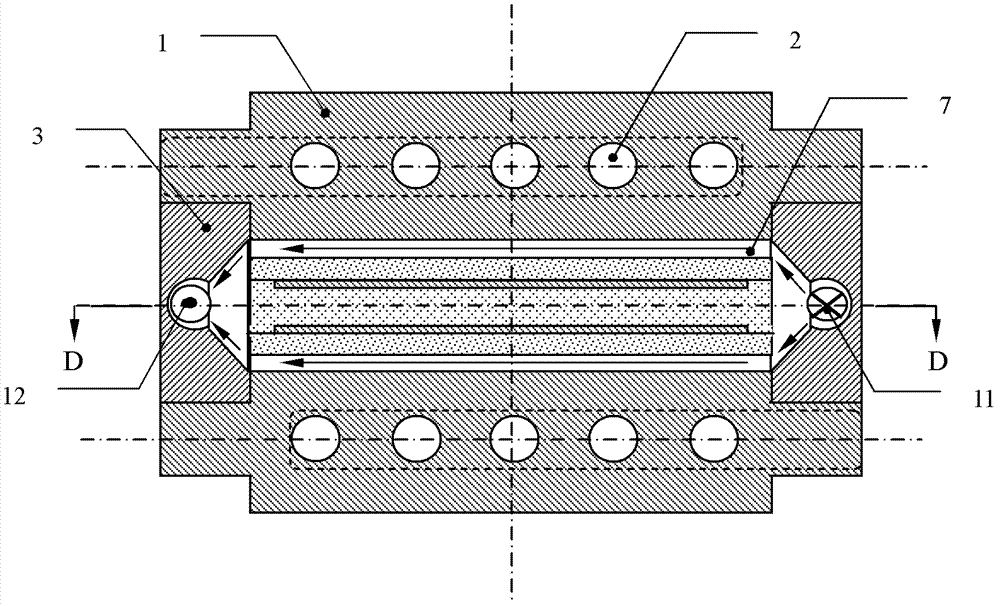

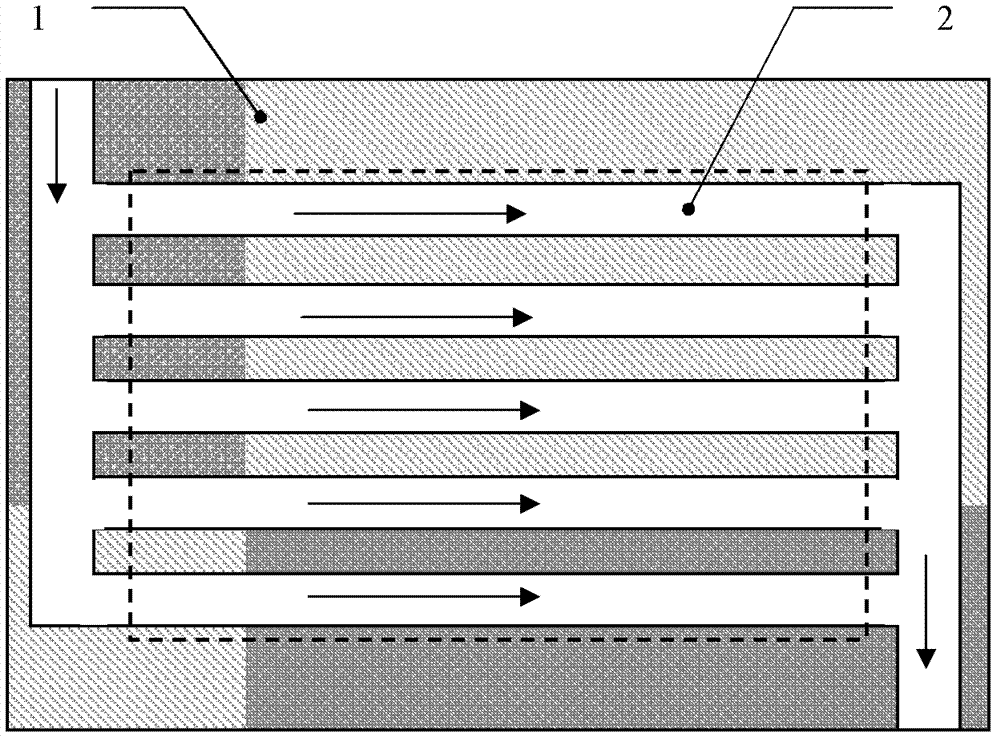

[0030] The unit module proposed by the present invention for constructing the laminated low-temperature plasma reactant has three structures in total. The first structure is as follows: figure 1 and figure 2As shown, it includes an upper ground electrode 1 , a lower ground electrode 13 , a frame 3 , a supporting dielectric wire 6 , a dielectric plate 8 , an upper high voltage electrode 9 , a lower high voltage electrode 14 , a high voltage lead 5 and a high voltage terminal 4 . Each of the upper ground electrode 1 and the lower ground electrode 13 is provided with a water-cooling channel 2, and the two ends of the upper ground electrode 1 and the lower ground electrode 13 are respectively provided with bosses, and the two sides of the upper ground electrode 1 and the lower ground electrode 13 respectively form working surfaces . The surrounding frame 3 is fixed between the upper ground electrode and the lower ground electrode through the bosses at both ends of the upper grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com