Multiferroic rare earth doped ferrate materials and preparation method thereof

A rare earth doping, multiferroic technology, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., to achieve the effects of excellent product performance, mild synthesis conditions, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Take 20mmol of FeCl 3 , added to a 30ml reaction kettle, and 20mmol of LaCl was added to the kettle 3 and 20mmol of ZnCl 2 , at this time La 3+ and Fe 3+ The molar ratio is 1:1; then add 20ml of ethylene glycol solution to the kettle, and after magnetically stirring to dissolve, add 1g of potassium acetate and 1g of polyethylene glycol 4000, and continue to stir until completely dissolved; heat at 250°C for 24 hours, The resulting black precipitate is washed with deionized water and dried between 40°C and 80°C to obtain spinel-type ZnFeLaO with a particle size of 0.02-5 microns 4 multiferrous compounds.

Embodiment 2

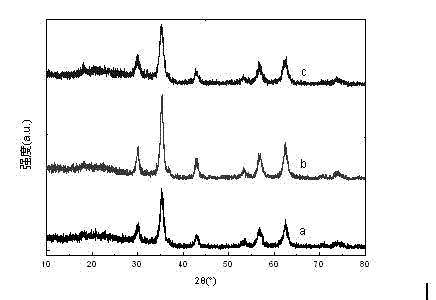

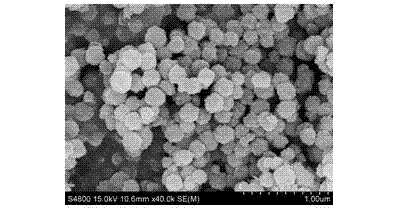

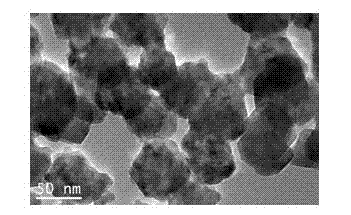

[0042] Experimental method is the same as embodiment 1, but the reaction proportion is different, FeCl 3 Change to 19mmol, LaCl 3 Change to 1mmol, ZnCl 2 Change it to 10mmol to obtain spinel ZnFe with a particle size of 0.02-5 microns 1.9 La 0.1 o 4 multiferrous compounds. (powder XRD diffraction of samples see figure 1 a, Scanning electron microscope see figure 2 , hysteresis loop see Figure 7 , indicating that ZnFe 1.9 La 0.1 o 4 It is a compound with spinel structure, the particle appearance is spherical, and has ferromagnetic properties. )

Embodiment 3

[0044] The experimental method is the same as in Example 1, except that the reaction ratio is different, and the control La 3+ with Fe 3+The molar ratio is 0.2:1.8, that is, spinel-type ZnFe with a particle size of 0.02-5 microns can be obtained 1.8 La 0.2 o 4 multiferrous compounds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com