Preparation method of F-doped gamma-ferric oxide hollow microspheres with adjustable bandwidth

A technology of ferric oxide and fluorine doping, which is applied in the direction of iron oxide, iron oxide/iron hydroxide, nanotechnology for materials and surface science, etc., and can solve the problems of difficult mass preparation and large-scale production, complex processes, etc. problem, to achieve the effect of low cost, simple process and excellent optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

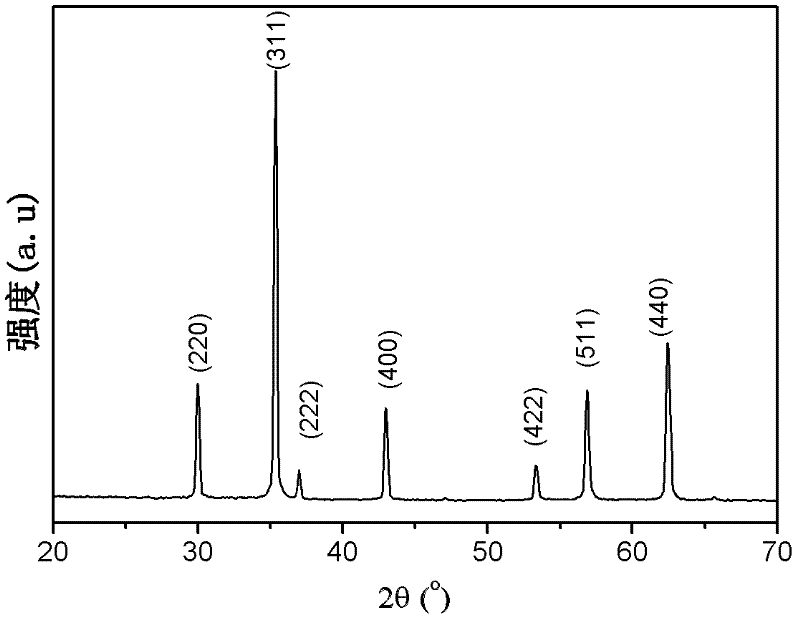

[0029] The steps and conditions of the fluorine-doped γ-ferric oxide hollow microspheres prepared in this example are as follows:

[0030] 1) 16mmolFeCl 3 Dissolve in 40ml ethylene glycol, stir well to form FeCl 3 A clear solution with a concentration of 0.4mol / 1, i.e. the first solution;

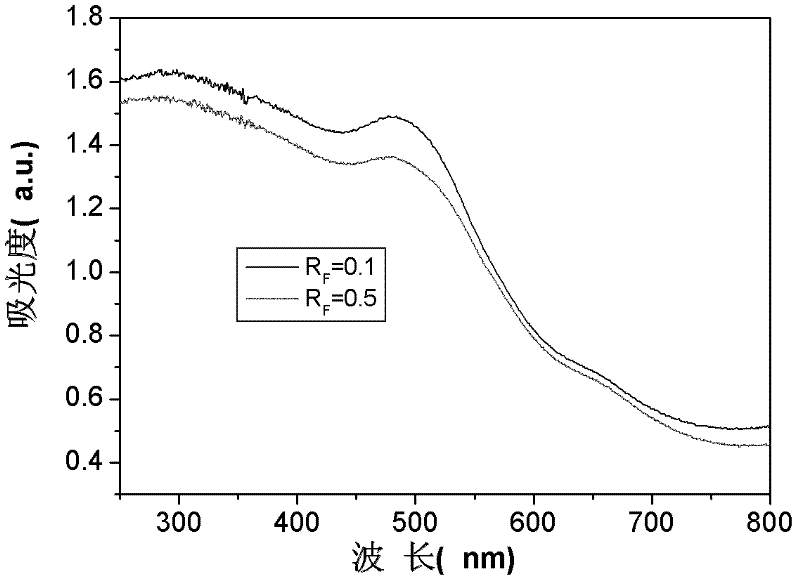

[0031] 2) NH 4 F follow R F =0.1 was added to the first solution, fully stirred to form the second solution;

[0032] 3) Add ethylenediamine dropwise to the second solution, the volume ratio of the added amount to ethylene glycol is 0.2:1, and fully stir to form the third solution;

[0033] 4) Transfer the third solution obtained above into a closed reaction vessel, and keep it warm for 12 hours under the condition of 200° C. to obtain a precipitate;

[0034] 5) Finally, the precipitate obtained in the above step 4) was washed several times with dehydrated ethanol and deionized water, dried, and calcined at 250°C to obtain the fluorine-doped γ-iron sesquioxide hollow microstructure. bal...

Embodiment 2

[0037] Except step 1) use Fe(NO 3 ) 3 , Fe 2 (SO 4 ) 3 Except for its mixture, other steps and conditions are the same as in Example 1, and fluorine-doped γ-iron sesquioxide hollow microspheres can also be obtained.

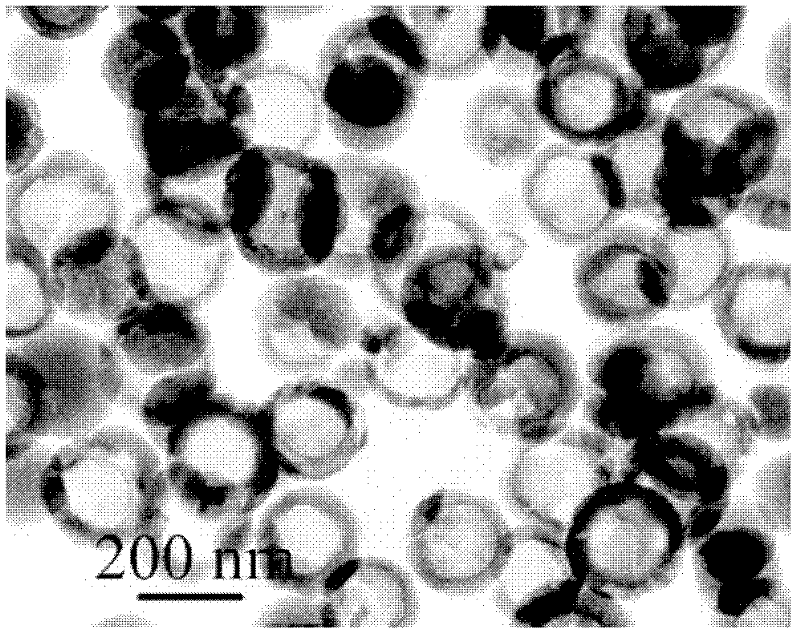

[0038] The transmission electron microscope (TEM) photo and the electron diffraction pattern (ED) of the fluorine-doped gamma-iron sesquioxide hollow microspheres prepared in the present embodiment are respectively as follows figure 2 shown, from figure 2 It can be seen that the edge and center of the prepared product have obvious contrast, wherein the edge is darker and the center is lighter, which shows that the prepared sample has a hollow structure, good dispersion, uniform particle size, and a size of 200 ~300nm, the wall thickness is 20~40nm;

Embodiment 3

[0040] This example prepares fluorine-doped γ-ferric oxide hollow microspheres, the steps and conditions are as follows:

[0041] 1) Fe 2 (SO 4 ) 3 Dissolve in 40ml ethylene glycol, stir well to form Fe 2 (SO 4 ) 3 The concentration is the first solution of 0.05mol / 1;

[0042] 2) Put NaF in accordance with R F =0.5 was added to the first solution, fully stirred to form the second solution;

[0043] 3) adding ethylenediamine dropwise to the second solution, the volume ratio of the added amount to ethylene glycol is 0.35:1, fully stirring to form the third solution;

[0044] 4) transfer the third solution obtained above into a closed reaction vessel, and keep it warm for 16 hours under the condition of 220° C. to obtain a precipitate;

[0045] 5) Finally, the precipitate obtained in the above step 4) was washed several times with dehydrated ethanol and deionized water, dried, and calcined at 250°C to obtain the fluorine-doped γ-iron sesquioxide hollow microstructure. ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com