High-effective composite flocculant for treating low-turbidity water and preparation method of high-effective composite flocculant

A composite flocculant and low turbidity technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of harsh reaction conditions, complicated preparation process, and prone to gelation, etc., and achieve stable and easy-to-control reaction conditions, Good response and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

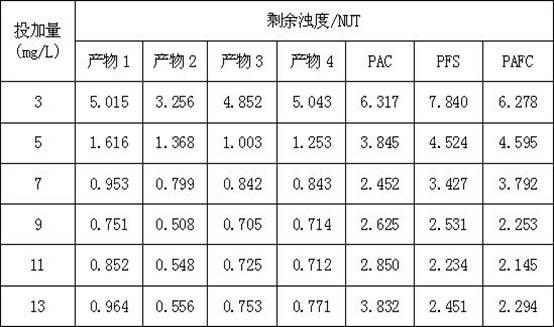

Examples

Embodiment 1

[0029] A high-efficiency composite flocculant for treating low-turbidity water, its raw materials contain the following components by weight: 6.8 parts of sodium aluminate, 6.5 parts of water glass solution, 69.5 parts of aluminum sulfate solution, 17.2 parts of water, and its preparation method Include the following steps:

[0030] 1) Preparation of sodium aluminate stable solution: Dissolve 36.4g of sodium aluminate and 0.44g of sodium tartrate in 91g of water, heat to boil, cool to room temperature when the mixed solution becomes clear, and obtain sodium aluminate stable solution A;

[0031] 2) Preparation of activated silicic acid with a low degree of polymerization: take 34.5g of water glass solution, adjust the pH to 1 with a mixture of oxalic acid and ammonium sulfate with a molar ratio of 1:2, and let it stand to obtain a transparent solution with a slight blue fluorescence B;

[0032] 3) Polymerization reaction: at room temperature, add solution B to 370g of aluminum...

Embodiment 2

[0034] A high-efficiency composite flocculant for treating low-turbidity water, its raw materials contain the following components by weight: 8.4 parts of sodium aluminate, 6.8 parts of water glass solution, 63.6 parts of aluminum sulfate solution, 21.2 parts of water, and its preparation method Include the following steps:

[0035] 1) Preparation of sodium aluminate stable solution: Dissolve 42.5g of sodium aluminate and 0.59g of sodium gluconate in 106g of water, heat to boil, cool to room temperature when the mixed solution becomes clear, and obtain sodium aluminate stable solution A;

[0036] 2) Preparation of activated silicic acid with a low degree of polymerization: Take 34.5g of water glass solution, adjust the pH to 2 with a mixture of citric acid and ammonium sulfate with a molar ratio of 1:1, and let it stand still to obtain a slightly blue fluorescent transparent Solution B;

[0037] 3) Polymerization reaction: at room temperature, add solution B to 321g of alumin...

Embodiment 3

[0039] A high-efficiency composite flocculant for treating low-turbidity water, its raw materials contain the following components by weight: 8.6 parts of sodium aluminate, 5.1 parts of water glass solution, 64 parts of aluminum sulfate solution, 22.3 parts of water, and its preparation method Include the following steps:

[0040] 1) Preparation of sodium aluminate stable solution: Dissolve 42.7g of sodium aluminate and 1.45g of potassium tartrate in 110g of water, heat to boil, cool to room temperature when the mixed solution becomes clear, and obtain sodium aluminate stable solution A;

[0041] 2) Preparation of activated silicic acid with a low degree of polymerization: take 25.5g of water glass solution, adjust the pH to 1.5 with a mixture of oxalic acid, acetic acid and ammonium sulfate with a molar ratio of 1:1:5, and let it stand still to obtain a slightly blue color Fluorescent transparent solution B;

[0042] 3) Polymerization reaction: at room temperature, add solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com