Special functional melt granulated humic acid fertilizer and production method thereof

A technology of melt granulation and humic acid, applied in application, fertilization equipment, fertilizer mixture, etc., can solve the problems of few reports on fertilizers, achieve the effects of improving soil structure, reducing production costs, and improving fertilizer utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

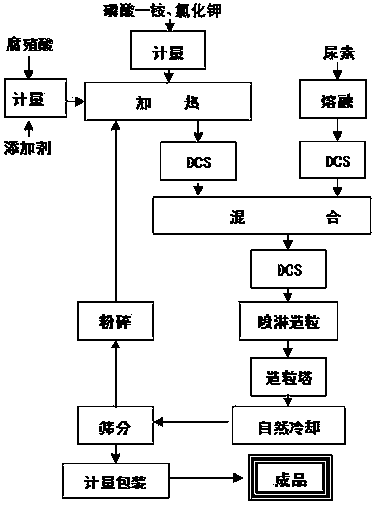

Method used

Image

Examples

Embodiment 1

[0056] Melt 494 parts of urea at a high temperature to about 140°C, enter the buffer tank, pressurize it through a delivery pump, and pump it into the top mixer;

[0057] After measuring 261 parts of monoammonium phosphate, 126 parts of potassium chloride, 100 parts of humic acid and 19 parts of additive calcium powder, send them into the mixer and mix them well. Heat it to about 90°C, and send it to the top silo with a bucket elevator;

[0058] The hot mixture in the silo at the top of the tower is sent to the above-mentioned mixer after being measured by a spiral weighing scale, and mixed by a high-speed shear mixer to make a thin paste material. The temperature is controlled at about 110 ° C, and the particulate impurities are filtered out by a vibrating filter. After overflowing to the granulation nozzle, under the centrifugal force of the rotation and shearing of the nozzle, the mixture is evenly sprayed into small spherical droplets. Slowly falling, after heat exchange ...

Embodiment 2

[0060] Get 460 parts of urea, 341 parts of monoammonium phosphate, 81 parts of potassium chloride, 100 parts of humic acid and 18 parts of fillers as raw materials, and the production process is the same as in Example 1;

[0061] The obtained product specification is N-P2O5-K2O(25-15-5).

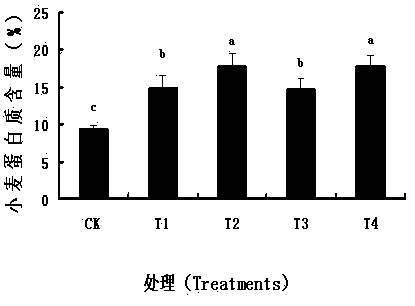

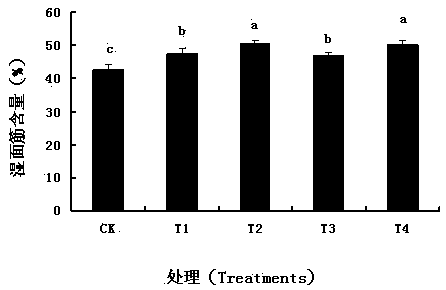

[0062] In order to test the application of melt granulated humic acid functional special fertilizer in agriculture, Stanley Company commissioned the National Wheat Research Center to conduct an experiment. This experimental study compares the effects of different fertilizers on wheat yield, nutrient utilization, and plant physiology and ecology, and evaluates the economic benefits of various fertilizers, providing a scientific basis for the promotion and application of melt granulated humic acid functional fertilizers.

[0063] 1. Test material

[0064] The experiment was carried out at the Jiaozuo Wenxian Base of the National Wheat Research Center. Wenxian County is located in the northwes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com