Method for preparing concrete superplasticizer by utilizing synthesized aspirin waste liquor

A technology of high-efficiency water-reducing agent and aspirin, which is applied in the field of preparing high-efficiency water-reducing agent for concrete, can solve environmental pollution and other problems, and achieve the effect of solving environmental pollution problems, high water-reducing rate, and not easy to bleed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

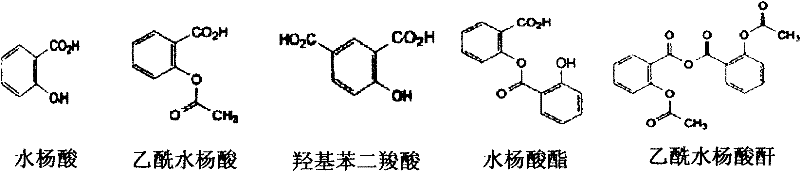

[0044] Add 133g (1.3mol) of chemically pure acetic anhydride to a 500ml four-necked flask equipped with a stirrer, a thermometer and a reflux condenser, add 0.5ml of concentrated sulfuric acid, heat on a water bath at 80°C, and add chemically pure water in batches under stirring 138g (1.0mol) of citric acid, maintain the reaction temperature at 80-85°C, and continue to stir and react for 60 minutes after the addition is complete. The reaction solution was cooled to 40°C, 5.4g of distilled water was added to decompose excess acetic anhydride, further cooled to 10°C for crystallization, the aspirin crystals were separated by filtration, washed with a small amount of water to obtain 153g of aspirin products (after drying), and the synthesis yield was 85%. Reaction mother liquor is about 124g. Distill the reaction mother liquor with a rotary thin film evaporator at -0.8Mpa vacuum, reclaim about 86.4g of acetic acid, and reclaim about 30g of phenolic residue.

Embodiment 2

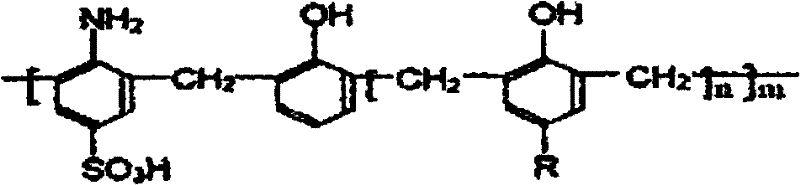

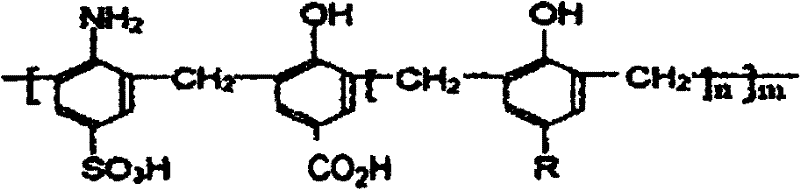

[0046] In a four-necked flask equipped with a thermometer, a stirrer, a dropping funnel and a reflux condenser, add 30 g of recovered phenolic residues, add 100 g of deionized water, and adjust the pH of the solution to 10-11 with 30% sodium hydroxide to make most of the residues Dissolve and remove the insoluble residue by filtration to obtain the sodium salt solution of the phenolic residue. Add 15.0 g of p-aminobenzenesulfonic acid to the solution, stir until it is completely dissolved, adjust the pH to 8.0-8.5 with 30% sodium hydroxide solution, and start to add 30.4 g of 37% formaldehyde solution dropwise when the temperature is raised to 90-95°C. After the addition, carry out the condensation reaction at reflux temperature for 6 hours, then adjust the pH to 10-11 with 30% sodium hydroxide solution, continue the reflux condensation for 1 hour, then add 1.0 g of urea to completely convert the residual formaldehyde, concentrate in vacuo, and cool to obtain 40% amino aromati...

Embodiment 3

[0049] In a four-necked flask equipped with a thermometer, a stirrer, a dropping funnel, and a reflux condenser, add 15 g of recovered phenolic residues, add 100 g of deionized water, and adjust the pH of the solution to 10-11 with 30% sodium hydroxide to make most of the residues Dissolve and remove the insoluble residue by filtration to obtain the sodium salt solution of the phenolic residue. Add 10 g of phenol to the solution, add 15 g (0.15 mol) of p-aminobenzenesulfonic acid, stir until completely dissolved, adjust the pH to 8.0-8.5 with 30% sodium hydroxide solution, and start adding 37 % formaldehyde aqueous solution 30.4g, after the dropwise addition, carry out condensation reaction at reflux temperature for 6 hours, then adjust pH 10-11 with 30% sodium hydroxide solution, continue reflux condensation for 1 hour, then add 1.0g urea to completely convert residual formaldehyde , concentrated in vacuo, and cooled to obtain a 40% aminoarene sulfonate high-efficiency water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com