Phosphate starch biodegradable film and preparation method thereof

A technology of biodegradable film and phosphate ester, which is applied in the field of environmental science and natural polymer materials, can solve problems such as the production of ideal complete biodegradable materials, and achieve the protection of ecological environment, elongation at break and tensile strength The effect of increased strength and high technological content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

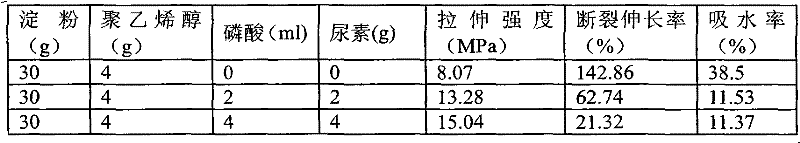

Embodiment 1

[0022] Commercially available high-quality cornstarch is selected, processed by freeze-drying, and then passed through a 40-mesh sieve. Then 30g of the sieved sample was added to a three-necked flask together with 4g of polyvinyl alcohol and 10ml of glycerin, and dissolved in 500ml of distilled water; at the same time, the temperature was adjusted to 60°C, and the sample was heated in a water bath and magnetically stirred. After stirring for 1 hour, 14ml of glyoxal and 3.2g of FeCl were added to the flask 3 ·6H 2 O and other reagents, then adjust the temperature to 80°C, heat in a water bath and stir magnetically for 30 minutes. Starch reaches a certain viscosity after swelling, gelatinization, and cross-linking reactions. Take out the reaction product, spread it evenly on the polyester sheet, put it in an oven, and dry it at 50°C. When the flat film is not sticky, take out the polyester sheet and let it cool naturally in the air, then peel off the film and seal it. Set asi...

Embodiment 2

[0024] Commercially available high-quality cornstarch is selected, processed by freeze-drying, and then passed through a 40-mesh sieve. Then add 30 g of the sieved sample into a three-neck flask together with 4 g of polyvinyl alcohol, 2 g of urea, 2 ml of phosphoric acid, and 10 ml of glycerin, and dissolve it in 500 ml of distilled water; at the same time, adjust the temperature to 60 ° C, heat the sample in a water bath and magnetically stir the sample. After stirring for 1 hour, 14ml of glyoxal and 3.2g of FeCl were added to the flask 3 ·6H 2 0 and other reagents, then adjust the temperature to 80°C, heat in a water bath and stir magnetically for 30 minutes. Starch reaches a certain viscosity after swelling, gelatinization, and cross-linking reactions. Take out the reaction product, spread it evenly on the polyester sheet, put it in an oven, and dry it at 50°C. When the flat film is not sticky, take out the polyester sheet and let it cool naturally in the air, then peel o...

Embodiment 3

[0026] Commercially available high-quality cornstarch is selected, processed by freeze-drying, and then passed through a 40-mesh sieve. Then add 30g of the sieved sample into a three-necked flask together with 4g of polyvinyl alcohol, 4g of urea, 4ml of phosphoric acid, and 10ml of glycerin, and dissolve in 500ml of distilled water; at the same time, adjust the temperature to 60°C, heat the sample in a water bath and magnetically stir the sample. After stirring for 1 hour, 14ml of glyoxal and 3.2g of FeCl were added to the flask 3 ·6H 2 O and other reagents, then adjust the temperature to 80°C, heat in a water bath and stir magnetically for 30 minutes. Starch reaches a certain viscosity after swelling, gelatinization, and cross-linking reactions. Take out the reaction product, spread it evenly on the polyester sheet, put it in an oven, and dry it at 50°C. When the flat film is not sticky, take out the polyester sheet and let it cool naturally in the air, then peel off the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com