Conducting resin for scanning electronic microscope and preparation method thereof

An electron microscope and conductive resin technology, applied in the field of material processing, can solve problems such as high cost, sample surface damage, and inability to analyze samples chemically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

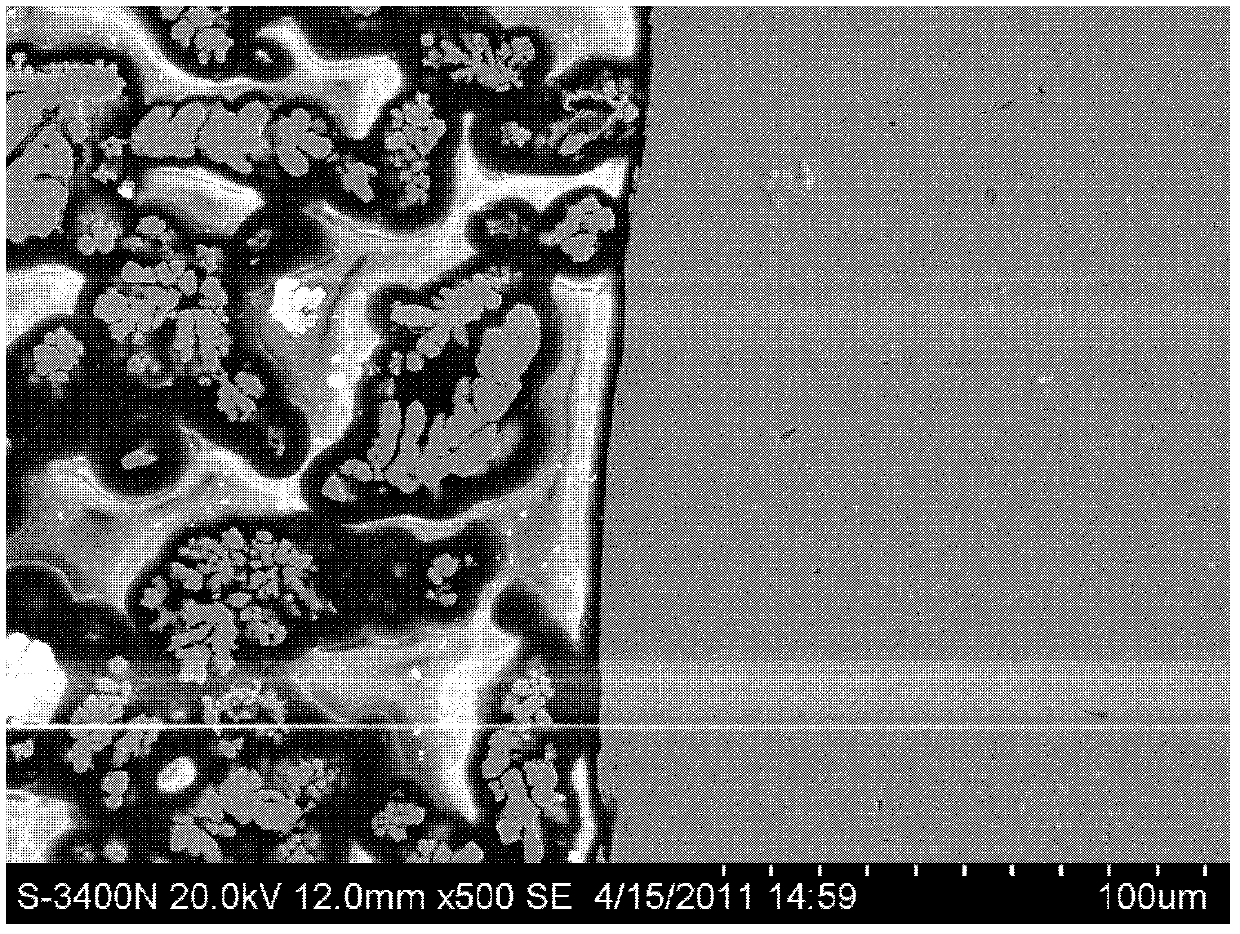

[0039] In order to make the plastic conductive, the present invention uses raw materials: epoxy resin as the substrate, ethylenediamine as the curing agent, silver-coated copper powder as the conductive particles (metal silver 18%, metal copper 82%; particle size is 30%). ~50μm). Required experimental equipment: glass rod, medicine spoon, polishing liquid, polishing cloth, plastic cup, 5 cylindrical molds, and 5 copper pieces of internal organization to be observed, electronic balance. Specific methods include the following:

[0040] 1. Weigh 80 g of epoxy resin, 8 g of ethylenediamine, and 160 g of silver-coated copper powder with an electronic balance in proportion and place them in three identical plastic cups.

[0041] 2. Add ethylenediamine to the plastic cup filled with epoxy resin and stir evenly.

[0042] 3. Slowly add silver-coated copper powder, stirring while adding it, to prevent too fast curing to form agglomerates, resulting in uneven dispersion of the remaining silve...

Embodiment 2

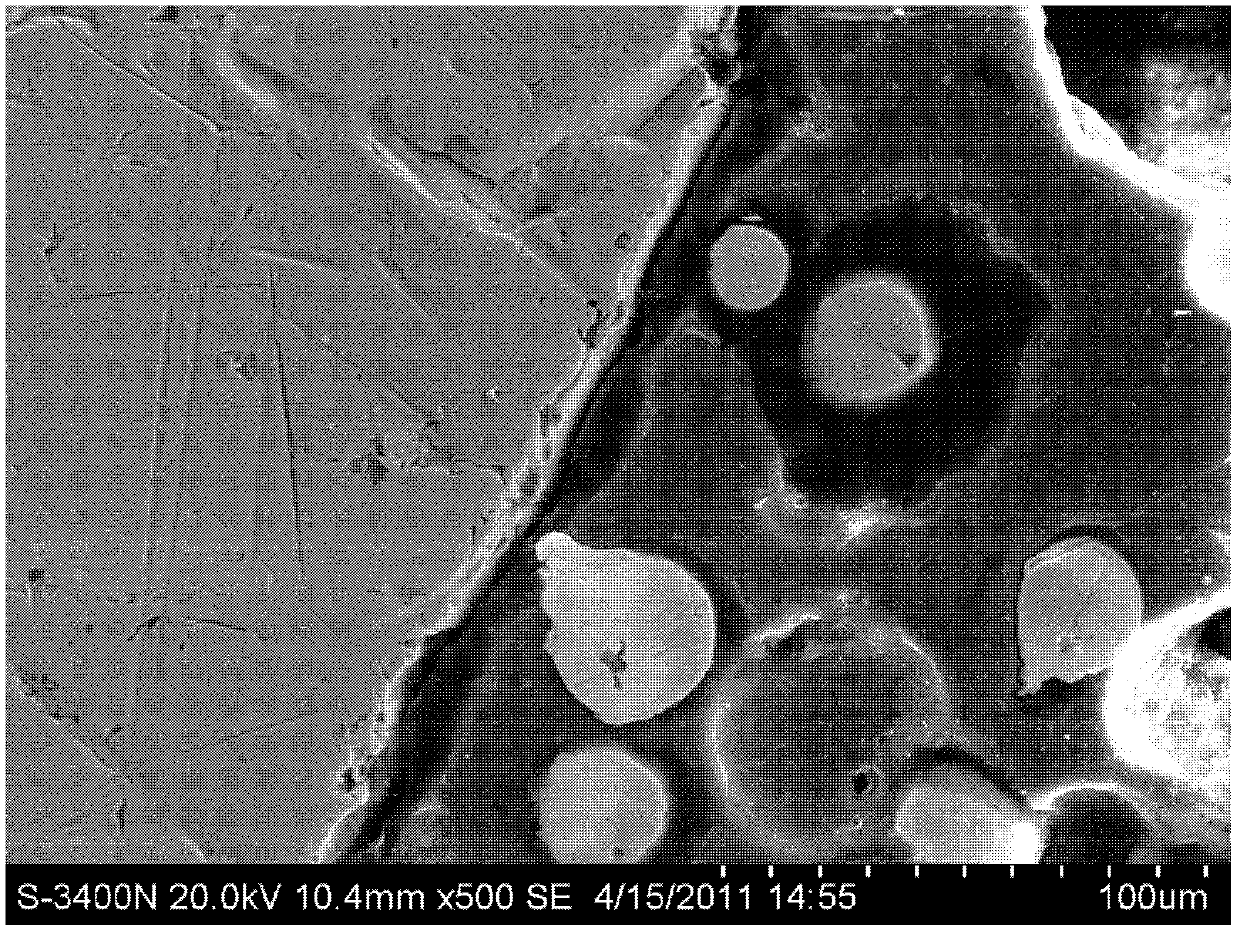

[0050] In order to reduce the cost and make the experiment more economical, the present invention can also replace the expensive silver-coated copper powder with relatively inexpensive tin-silver copper powder. Experimental raw materials: base material epoxy resin, curing agent ethylenediamine, conductive particles tin silver copper powder (metal silver 3%, metal copper 0.5%, 96.5% metal tin; particle size is 30-50μm in diameter), required experiment Utensils: glass rods, medicine spoons, polishing liquid, polishing cloth, plastic cups, 5 cylindrical molds, and 5 copper plates for observation of internal tissues, electronic balance. Specific methods include the following:

[0051] 1. Use an electronic balance to weigh out 80g of epoxy resin, 8g of ethylenediamine, and 160g of tin, silver and copper powder, and place them in three different plastic cups.

[0052] 2. Add ethylenediamine to the plastic cup filled with epoxy resin and stir evenly.

[0053] 3. Slowly add tin-silver-copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com