Rubber material for windscreen wipers, preparation method thereof and process for producing windscreen wiper from the rubber material

A technology of wiper and rubber strips, which is applied in the field of auto parts, can solve the problems of high temperature resistance and cold resistance of wiper rubber strips, difficulty in disposal of rubber strips, and damage to soil ecology, etc. The use of sulfur additives, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

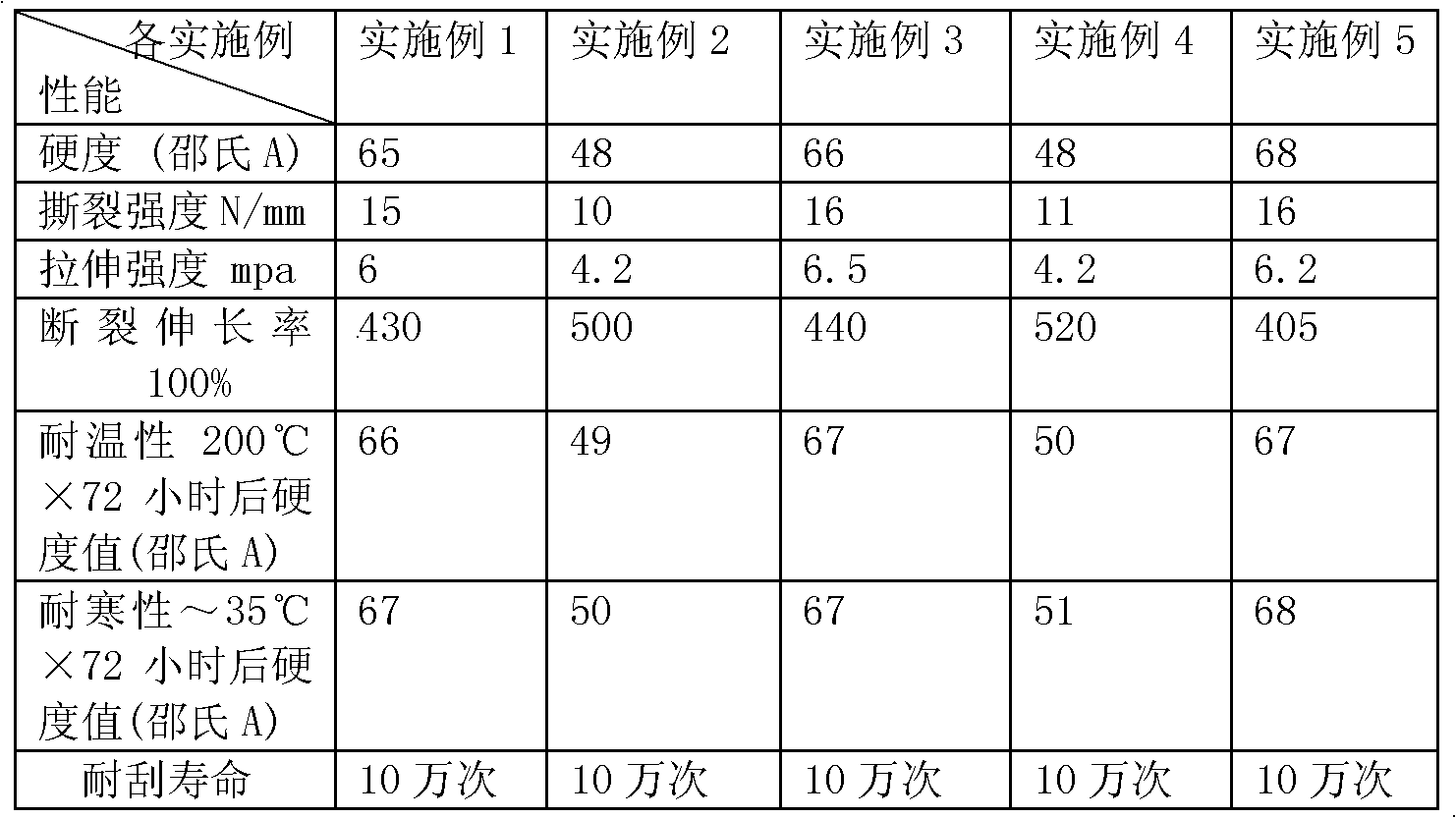

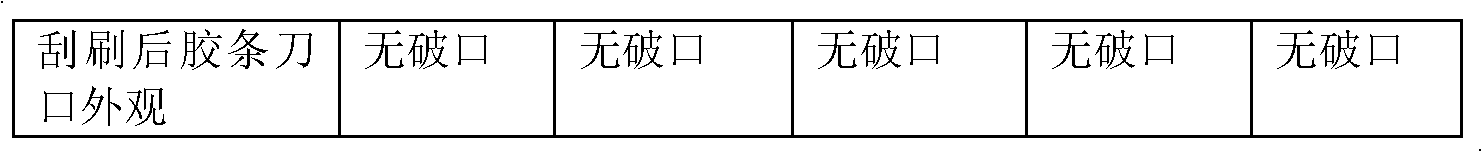

Examples

Embodiment 1

[0041] 1. Composition of rubber material:

[0042] 100 parts of methyl vinyl silicone rubber;

[0043] Fumed silica N20 50 parts;

[0044] Hydroxyl silicone oil (viscosity is 25cp, hydroxyl content is 8%) 1.5 parts;

[0045] 7.8 parts of phenylmethyl silicone oil;

[0046] Iron oxide black 0.2 part;

[0047] 1.2 parts of bis-2-4 vulcanizing agent.

[0048] Second, the preparation method of rubber:

[0049] 1) Mix fumed silica N20, hydroxyl silicone oil and benzyl silicone oil evenly to obtain a mixed material;

[0050] 2) Put the formula amount of methyl vinyl silicone rubber into the kneader at one time, open the cover and knead for 10 minutes, then divide the above mixed material into 3 times, and put the same amount into the kneader each time (the material to be put in for the first time After mixing evenly with methyl vinyl silicone rubber, the second input can be carried out, and the third input can be carried out after the second input material is evenly mixed with...

Embodiment 2

[0056] 1. Composition of rubber material:

[0057] 100 parts of methyl vinyl silicone rubber;

[0058] Fumed white carbon black N20 30 parts;

[0059] Hydroxyl silicone oil (viscosity is 30cp, hydroxyl content is 9%) 1.0 parts;

[0060] 5.0 parts of simethicone oil;

[0061] 0.2 parts of titanium dioxide;

[0062] 1.2 parts of bis-2-4 vulcanizing agent.

[0063] Second, the preparation method of rubber:

[0064]1) Mix fumed silica N20, hydroxyl silicone oil and dimethyl silicone oil evenly to obtain a mixed material;

[0065] 2) Put the formula amount of methyl vinyl silicone rubber into the kneader at one time, open the cover and knead for 12 minutes, then divide the above mixed material into 2 times, and put the same amount into the kneader each time (the material to be put in for the first time After mixing with methyl vinyl silicone rubber evenly, the second input can be carried out), after all the mixed materials are added, knead with a half-closed cover for 35 minu...

Embodiment 3

[0070] 1. Composition of rubber material:

[0071] 100 parts of methyl vinyl silicone rubber;

[0072] Fumed silica N20 40 parts;

[0073] Hydroxyl silicone oil (viscosity is 30cp, hydroxyl content is 8%) 2.5 parts;

[0074] 6 parts of fluorosilicone oil;

[0075] 1.5 parts of titanium yellow;

[0076] 0.8 part of bis-two-four vulcanizing agent.

[0077] Second, the preparation method of rubber:

[0078] 1) Mix fumed silica N20, hydroxyl silicone oil and fluorosilicone oil evenly to obtain a mixed material;

[0079] 2) Put the formula amount of methyl vinyl silicone rubber into the kneader at one time, open the cover and knead for 8 minutes, then divide the above mixed material into the kneader for 3 times (the first time, the second time and the third time The amount of input is 1 / 2, 1 / 4 and 1 / 4 of the total weight of the mixed material; the second input can be made after the first input material is mixed with methyl vinyl silicone rubber, and the second input The mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com