Novel modified nano silicon dioxide and composite coating prepared from same

A nano-silica, composite coating technology, applied in the direction of dyeing polymer organic compound treatment, coating, fibrous filler, etc., to achieve the effect of good dispersibility, improved scrub resistance, and improved comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

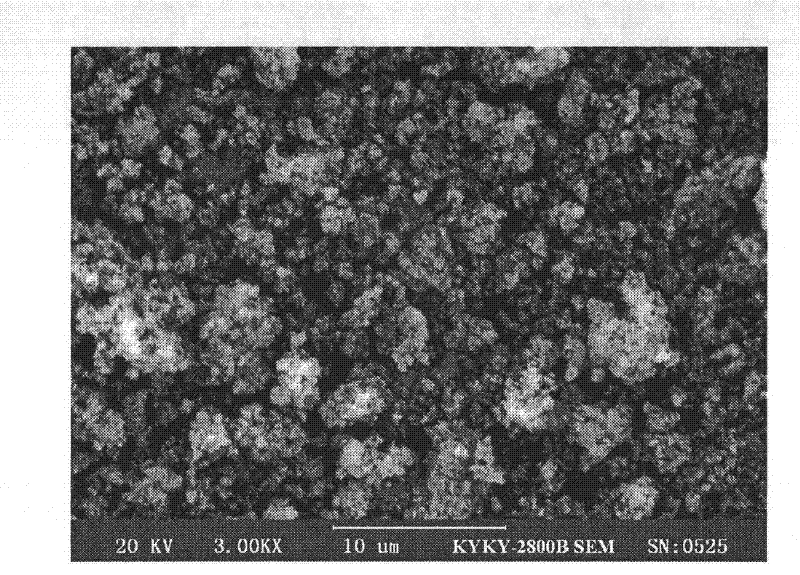

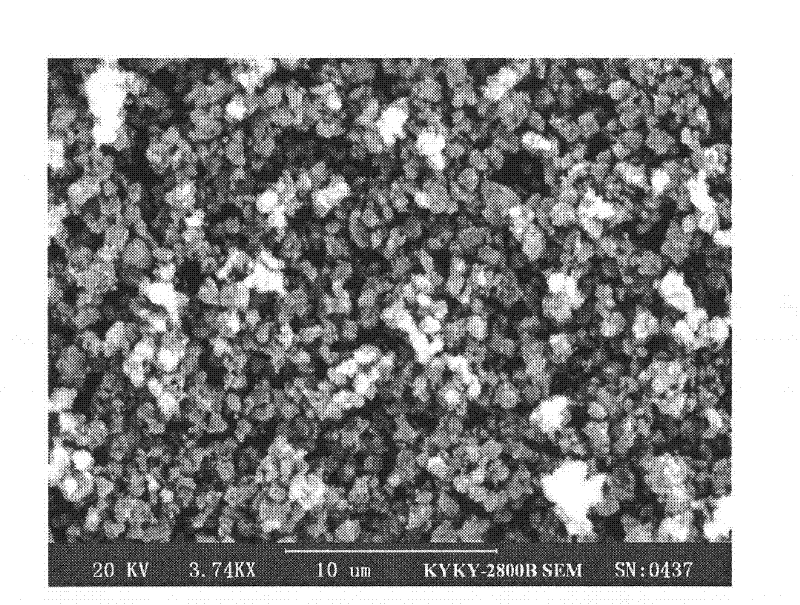

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be described in detail below through specific implementation steps.

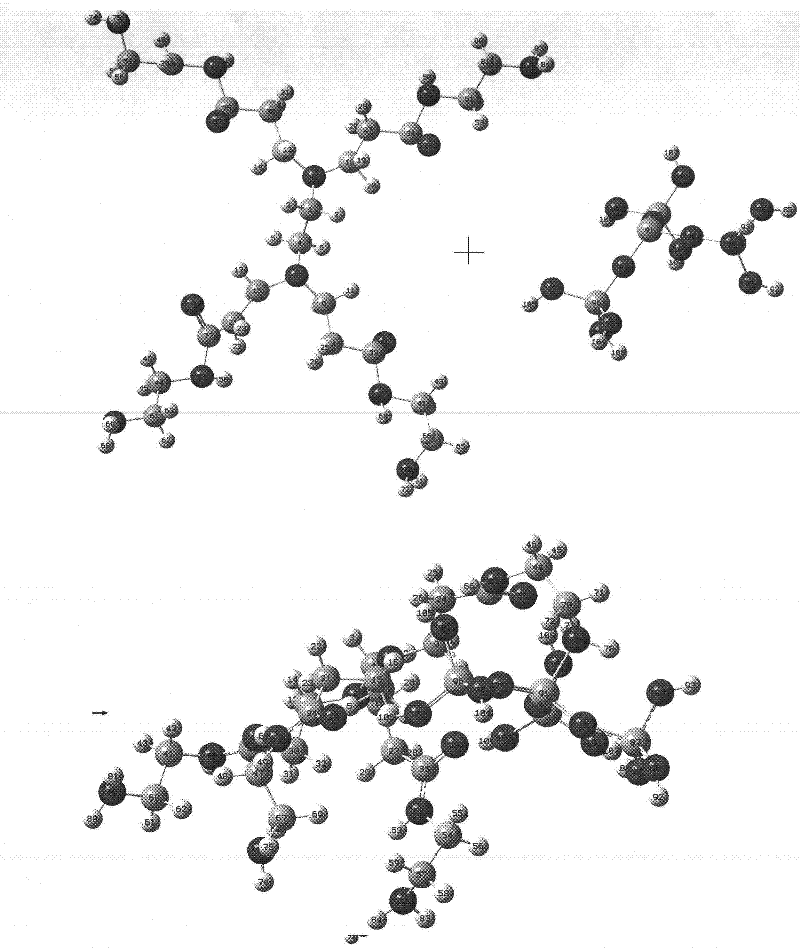

[0028] Modified nano silica preparation method of the present invention is as follows:

[0029] Step 1: Preparation of PAMAM template

[0030] (1) Preparation of 0.5 generation PAMAM: put 120g of methyl acrylate and 10g of methanol in a 400mL volumetric flask, stir magnetically at 5°C, pass He protection for 1h, add 10.5g of ethylenediamine and 27.5g of methanol dropwise with a dropping funnel The mixture of g was added dropwise for 1h and passed through He. After the dropwise addition was completed, the reaction was carried out at room temperature for 36h. Use a rotary evaporator to distill under reduced pressure (about 140 Pa, 40° C.) to remove unreacted methyl acrylate and methanol to obtain a slightly yellowish viscous liquid.

[0031] (2) Preparation of 1.0-generation PAMAM: Put 84g of ethylenediamine and 11g of methanol in a 500mL volumetric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com