Toughened alpha-cyanoacrylate adhesive and preparation method thereof

A cyanoacrylate and cyanoacrylate technology, applied in the direction of adhesives, non-polymer organic compound adhesives, etc., can solve the problems of slow curing speed, high brittleness of adhesives, decreased bonding strength, etc., and reduce molecular weight. Interaction force, improve product toughness, reduce the effect of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

[0016] Specific example 1: Toughening glue :The main ingredient is containing this group Polyurethane prepolymer—α-ethyl cyanoacrylate complex. Which contains this group 150 parts of polyurethane prepolymer and 500 parts of ethyl α-cyanoacrylate.

[0017] Contrast glue : The main component is 500 parts of ethyl α-cyanoacrylate.

[0018] The content of other components is the same, including 0.08 part of anionic polymerization inhibitor methanesulfonic acid and 0.35 part of free radical inhibitor p-methoxyphenol.

Embodiment 1

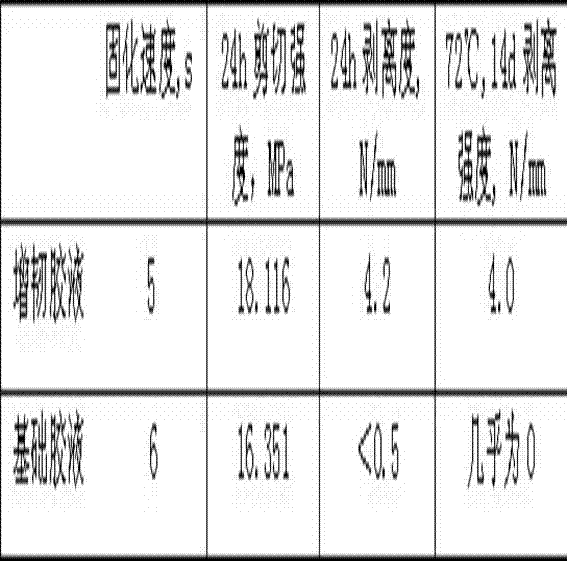

[0019] The curing speed, shear strength and peeling data tested in Example 1 are as follows:

[0020]

specific example 2

[0022] Toughening glue: the main component is containing this group Polyurethane prepolymer—

[0023] α-methyl cyanoacrylate complex, which contains this group Polyurethane

[0024] 80 parts of prepolymer, 180 parts of α-methyl cyanoacrylate;

[0025] Basic glue: the main component is α-methyl cyanoacrylate;

[0026] The content of other components is the same, including 0.04 parts of anionic polymerization inhibitor p-toluenesulfonic acid, 0.2 parts of free radical inhibitor hydroquinone, and 10 parts of thickener polymethyl methacrylate; in addition, thickening can be added according to the purpose. Agents, heat-resistant agents, reinforcing agents, pigments, fragrances, etc.; thickeners include: polymethacrylate, methacrylic acid ester copolymer, acrylic rubber, cellulose derivatives, polyvinyl acetate, etc.; heat-resistant The agent can be the sulfur-containing compound mentioned in EP579 796; the reinforcing agent includes: acrylic rubber, acrylonitrile copolymer, elastomer, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com