Process for producing directly mold-pressed fiber board

A technology of molding processing and production process, applied in fiber raw material processing, wood processing appliances, applications, etc., can solve the problems of cracks in the molding position of the board, less decorative door processing, waste of raw materials, etc., to prevent delamination and improve internal quality. And the effect of three-dimensional appearance, improved flatness and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

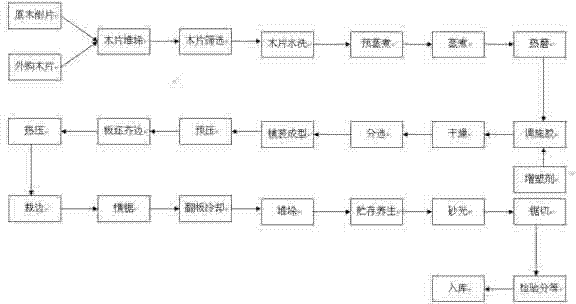

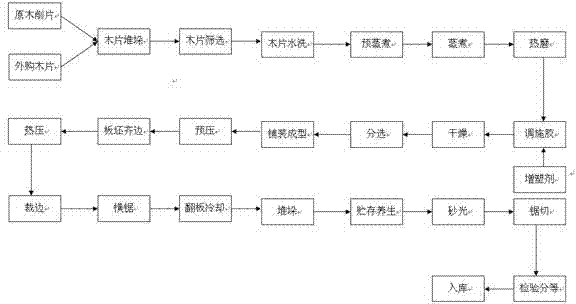

[0012] refer to figure 1 , the present invention is further illustrated by the following examples: long 40-60mm, wide 15-30mm, thick 2-6mm pine chips are washed to remove impurities such as silt on the surface of the wood chips. The washed wood chips are sent to the pre-cooking vat by the wood chip pump for initial softening, and then sent to the cooking vat for further softening through the cork screw. The steam pressure in the cooking cylinder is 0.70-0.80Mpa, and the cooking time is 4-6 minutes. After the wood chips are fully cooked, they enter the grinding chamber of the thermal refiner to defibrate, and at the same time, add molten paraffin accounting for 0.6-1.6% of the dry fiber weight into the grinding chamber; Poorly improve the grinding quality of fibers; the fibers treated in the thermal grinding process are screened by multi-layer screens, and the fibers in the following state and their ratio are selected to enter the next process, that is, the fiber quality that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com