Light energy-saving and heat-insulating composite wallboard and preparation method thereof

A thermal insulation composite and wall panel technology, applied in the field of thermal insulation wall panels, can solve problems such as strength, durability, flame retardancy and workability defects, and achieve the effects of easy cutting and assembly, no deformation, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Add 100 parts of 42.5R ordinary Portland cement, 10 parts of class II fly ash, 2 parts of gypsum, 0.3 parts of hydroxypropyl methylcellulose, 0.8 parts of naphthalene-based superplasticizer, and 0.1 part of calcium chloride Mortar mixer, dry mix with mixer.

[0033] 2) After wetting the light building ceramsite with water, mix it with cement, fly ash and other powders that are dry mixed uniformly, and then add 60 parts of water (the water-cement ratio is about 0.5) into the mortar mixer and stir to make the ceramsite Roll the grout evenly on the surface.

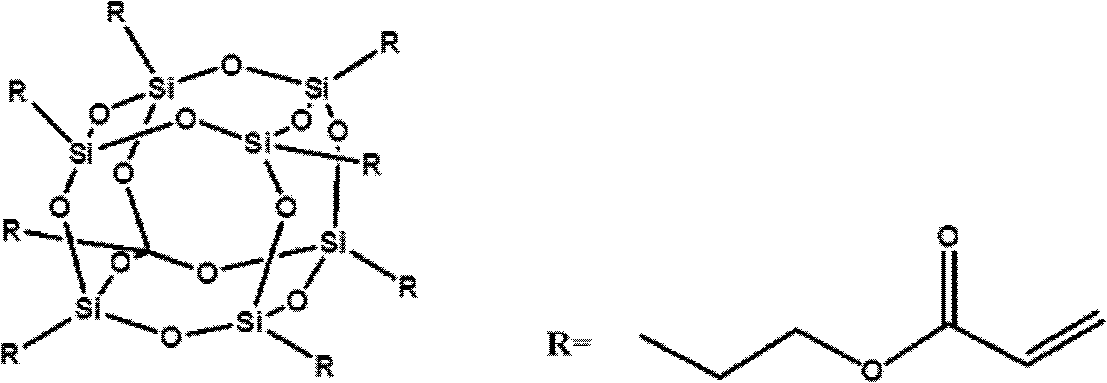

[0034] 3) Dissolve 0.1 part of Acrylo POSS (MA0736-Acrylo POSS Cage Mixture produced by American hybrid plastics company) with 0.3 part of ethanol, mix it with 0.5 part of redispersible latex powder, and add it to the mortar mixer.

[0035] 4) Add 0.3 parts of wd-11 cement foaming agent that is stirred into foam by a high-speed mixer into the mortar mixer, and stir evenly to form ceramsite mortar.

[0036] 5) Ins...

Embodiment 2~6

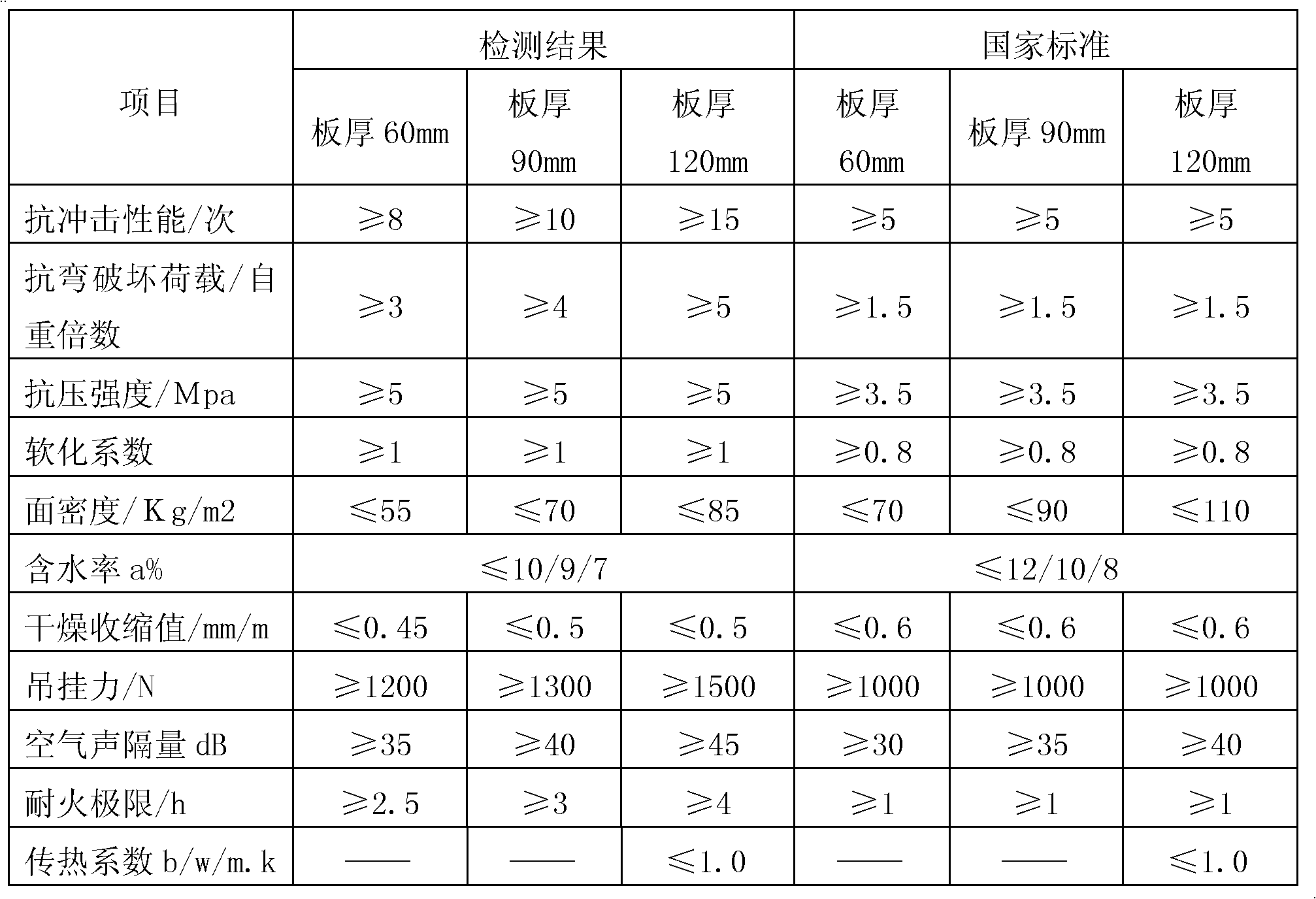

[0041]The preparation method is the same as in Example 1, except that the dosages of the various components of the ceramsite concrete are changed (see Table 2), and the test results of the physical properties of the obtained lightweight energy-saving and thermal insulation composite wallboard are the same as in Example 1.

[0042] Table 2 The amount of each component of ceramsite concrete (mass parts)

[0043]

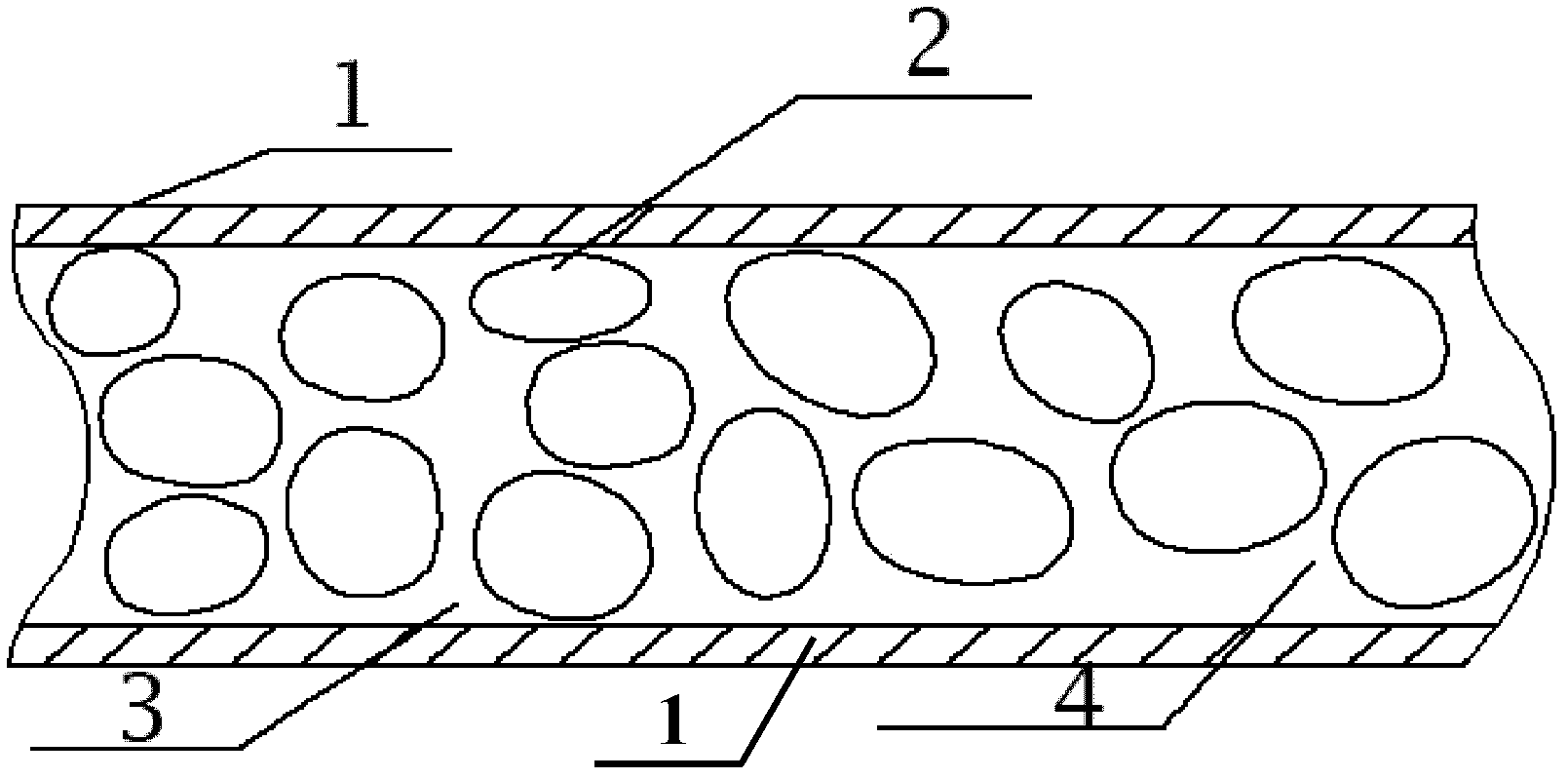

[0044] figure 1 A schematic diagram of the structural composition of the embodiment of the light-weight energy-saving thermal insulation composite wallboard according to the present invention is given. figure 1 Among them, the upper and lower surface boards 1 are calcium silicate boards for thermal insulation, and the core material 3 is composed of lightweight building ceramsite 2 and organic / inorganic nano-reinforced modified cement concrete 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com