Method for measuring antimony in powder cosmetic by microwave digestion and hydrofluoric acid-resistant sampling system ICP-MS (inductively coupled plasma-mass spectrometry)

An ICP-MS and microwave digestion technology, which is used in the preparation of test samples, measurement devices, and material analysis by electromagnetic means. Spectrum line simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] 1. Instruments and instrument conditions

[0047] 1.1 Instrument used: Inductively Coupled Plasma Mass Spectrometer (ICP-MS), model: Bruker 820 MS;

[0048] 1.2 HF-resistant atomizer, spray chamber, central tube made of platinum torch, platinum sampling cone (diameter 1.1mm), platinum skimmer cone (diameter 0.5mm);

[0049] 1.3 Instrument working conditions, see Table 1

[0050] Table 1. Reference Operating Conditions for Instruments

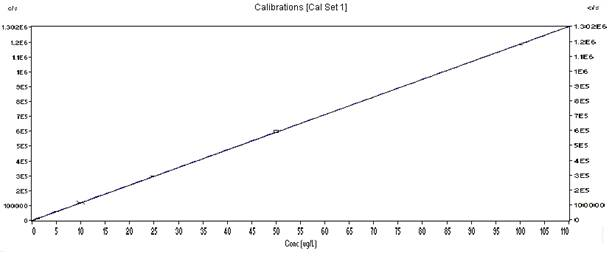

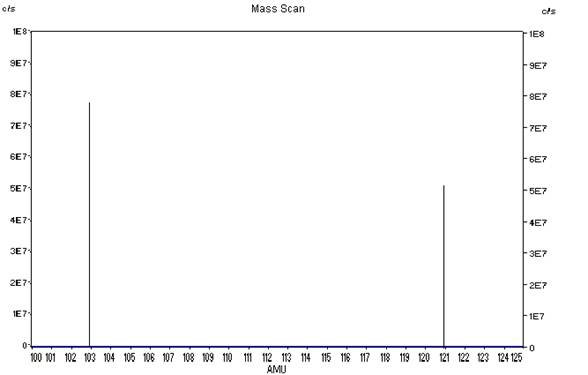

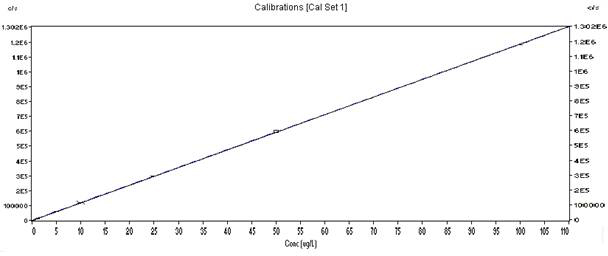

[0051] project Working parameters plasma flow 18 L / min Auxiliary gas flow 1.8 L / min Cooling gas flow 0.14 L / min Atomizing gas flow 0.90 L / min sampling depth 7.0 mm Plasma RF power 1.40kw Injection stabilization time 35 s pump speed 4 rpm scan mode Peak-jumping scan mode scan times Single order 30 times repeat times 5 dwell time 10ms Isotopes of analyte elements and internal standard elements 121 Sb, 103 Rh Hydrofluoric acid resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com