Device and method for producing hydrogen by biomass

A biomass and hydrogen technology, applied in hydrogen production and other directions, can solve the problems of low direct utilization rate, low hydrogen production rate, secondary pollution, etc., achieve good environmental effects and economic benefits, simple process, and promote reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

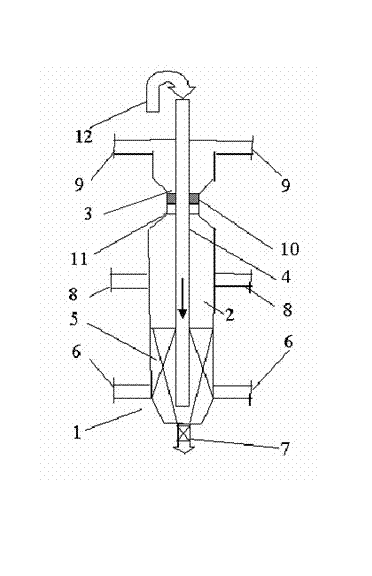

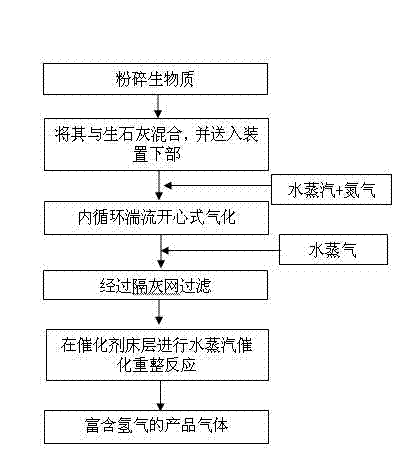

[0019] The biomass straw is crushed to an average particle diameter of 10 mm, and then 5% of the biomass mass fraction is added with quicklime, and the raw material is fed from the biomass feed port 6 of the device 1 at a rate of 10 kg / h; the volume fraction is 80 The mixed gas of % water vapor and 20% nitrogen is the gasification agent, and the total volume flow rate of the gasification agent is 30 / h, the gasification agent is sprayed into the device 1 from the blowing pipe inlet 12 of the device 1 through the blowing pipe 4 from top to bottom; the biomass is gasified at 700°C, and the crude gas produced by gasification is mixed with the water vapor inlet 8 spraying The incoming water vapor enters the catalyst bed 10 through the dust screen 11, and steam reforming reaction occurs under the action of the catalyst. The catalyst is a KF104 methanol steam reforming catalyst; the average catalyst particle diameter is 0.45mm, and the dosage is 10kg; within 1 hour of reaction time...

Embodiment 2

[0021] The waste plastics are pulverized to an average particle diameter of 5mm, and then adding quicklime accounting for 2% of the biomass mass fraction, the raw material is sent in at a rate of 10kg / h from the biomass feed port 6 of the device 1; the volume fraction is 90% The mixed gas of water vapor and 10% nitrogen is the gasification agent, and the total volume flow rate of the gasification agent is 30 / h, the gasification agent is sprayed into the bottom of the device 1 from the blowing pipe inlet 12 of the device 1 through the blowing pipe 4 from top to bottom; the biomass is gasified at 600°C, and the crude gas produced by gasification is mixed with the water vapor inlet 8 spraying The incoming water vapor enters the catalyst bed 10 through the dust screen 11, and steam reforming reaction occurs under the action of the catalyst. The catalyst is KF104 methanol steam reforming catalyst; the average catalyst particle diameter is 0.45mm, and the dosage is 10kg; within 1 ...

Embodiment 3

[0023] Municipal solid organic waste is sorted to remove metal and inorganic impurities, then crushed to an average particle diameter of 5mm, and then add quicklime accounting for 5% of the biomass mass fraction, and the raw material is fed from the biomass feed port 6 of the device 1 at a rate of Feed at 10kg / h; the gasification agent is a mixture of water vapor and 15% nitrogen with a volume fraction of 85%, and the total volume flow rate of the gasification agent is 30 / h, the gasification agent is sprayed into the bottom of the device 1 from the blowing pipe inlet 12 of the device 1 through the blowing pipe 4 from top to bottom; the biomass is gasified at 500°C, and the crude gas produced by gasification is mixed with the water vapor inlet 8 spraying The incoming water vapor enters the catalyst bed 10 through the dust screen 11, and steam reforming reaction occurs under the action of the catalyst. The catalyst is KF104 methanol steam reforming catalyst; the average cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com