Preparation method of dodecagonal zinc oxide micron rod

A zinc oxide micron and dodecagonal technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problems of difficulty in obtaining circular microcavities and the inability to realize circular optical crystal microcavities, etc., and reach the laser wavelength Adjustable, smooth border, laser mode adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The first step: cut the surface polished silicon wafer with the crystal plane orientation of the substrate as (100), and the substrate size of each silicon wafer after cutting is 3*4cm. Sonicate these small rectangular silicon substrates in acetone solution, ethanol solution and deionized water for 5 minutes in order to clean the surface of the silicon substrates.

[0021] The second step: prepare zinc acetate dihydrate solution and hexamethylenetetramine solution with concentrations of 0.02mol / L~0.05mol / L respectively, and stir at room temperature for 2 hours by magnetic stirring to make zinc acetate dihydrate and hexamethylenetetramine solution Methylenetetramine is fully soluble in deionized aqueous solution. Then the zinc acetate dihydrate solution and the hexamethylenetetramine solution were mixed at a volume ratio of 1:1, and 80 ml of the mixed solution was injected into a Teflon autoclave with a capacity of 80 ml.

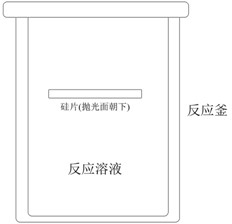

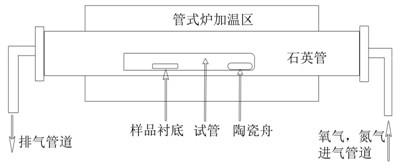

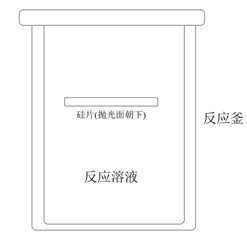

[0022] The third step: put the silicon wafer c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com