Surface-functionalized Fe3O4 nanoparticles as well as preparation method and application thereof

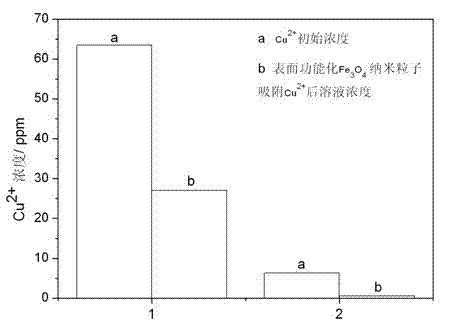

A surface functionalization, nanoparticle technology, applied in the field of Cu2+ enrichment and detection, can solve the problem of weak surface interaction of nanomaterials, inability to have different reactive functional groups on the surface of ferric oxide nanomaterials, unfavorable surface modification of nanomaterials and application and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

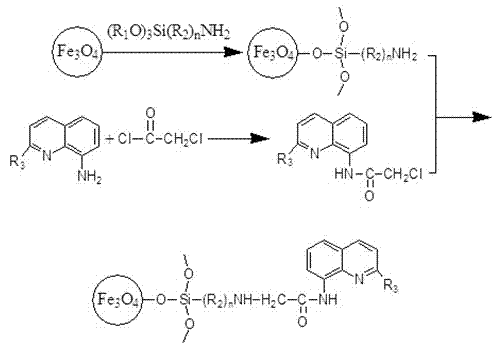

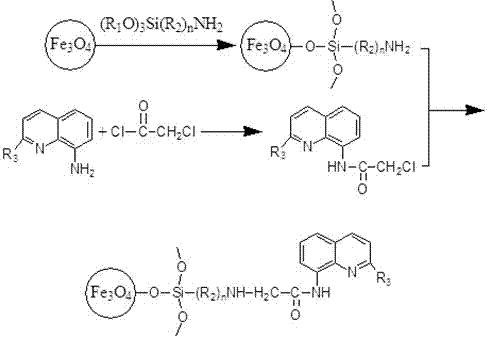

[0028] Embodiment 1: this surface functionalized Fe 3 o 4 The preparation method of nanoparticles comprises the following steps:

[0029] 1. Preparation of magnetic Fe3O4 nanoparticles

[0030] Take 2.0244 g FeCl 2 4H 2 O and 5.3904 g FeCl 3 ·6H 2 O was dissolved in 150 ml of distilled water, and under the condition of nitrogen protection, 55 ml of ammonia water was added dropwise with a constant pressure funnel at a rate of 5 ml / min, heated in a water bath at 65°C and stirred for 2 h, stopped heating, cooled naturally for 30 min, and distilled water , absolute ethanol, and toluene for 3 times, and vacuum-dried for 12 h to obtain magnetic Fe with uniform particle size distribution 3 o 4 Nanoparticles.

[0031] 2. Synthesis of 8-chloroacetylaminoquinoline derivatives

[0032] Take 0.95 g of 8-aminoquinoline in a round bottom flask, add 1 ml of triethylamine, then add 50 ml of dichloromethane solution, keep at 0°C for 30 min; Under light conditions, magnetic stirring...

Embodiment 2

[0041] Embodiment 2: this surface functionalized Fe 3 o 4 The preparation method of nanoparticles comprises the following steps:

[0042] 1. Preparation of magnetic Fe3O4 nanoparticles

[0043] Take 0.2 g FeCl 2 4H 2 O and 0.54 g FeCl 3 ·6H 2 O was dissolved in 50 ml of distilled water, and under the condition of nitrogen protection, 5.5 ml of ammonia water was added dropwise with a constant pressure funnel at a rate of 1 ml / min, heated in a water bath at 40°C and stirred for 6 h, then stopped heating, cooled naturally for 20 min, and then used distilled water, After washing with absolute ethanol and toluene for 3 times, and vacuum drying for 1 h, magnetic Fe with uniform particle size distribution was obtained. 3 o 4 Nanoparticles.

[0044] 2. Synthesis of 8-chloroacetylaminoquinoline derivatives

[0045] Take 0.095 g of 8-amino-2-ethylquinoline in a round bottom flask, add 0.1 ml of triethylamine, then add 5 ml of dichloromethane solution, keep at 0°C for 10 min; ...

Embodiment 3

[0053] Embodiment 3: this surface functionalized Fe 3 o 4 The preparation method of nanoparticles comprises the following steps:

[0054] 1. Preparation of magnetic Fe3O4 nanoparticles

[0055] Take 20g FeCl 2 4H 2 O and 54 g FeCl 3 ·6H 2 O was dissolved in 300 ml of distilled water, and under the condition of nitrogen protection, 100 ml of ammonia water was added dropwise with a constant pressure funnel at a rate of 10 ml / min, heated in a water bath at 90°C and stirred for 1 h, then stopped heating, cooled naturally for 60 min, and distilled water , absolute ethanol, and toluene for 3 times, and vacuum-dried for 24 h to obtain magnetic Fe with uniform particle size distribution. 3 o 4 Nanoparticles.

[0056] 2. Synthesis of 8-chloroacetylaminoquinoline derivatives

[0057] Take 9.5 g of 8-amino-2-methylquinoline in a round bottom flask, add 10 ml of triethylamine, then add 500 ml of dichloromethane solution, keep at 0°C for 60 min; then add 6 ml of chloroacetyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com