Surface-functionalized Fe3O4 nanoparticles as well as preparation method and application thereof

A surface functionalization, nanoparticle technology, applied in dyeing organosilicon compound treatment, dyed low molecular organic compound treatment, measurement device, etc. Reactive functional groups, unfavorable nanomaterial surface modifications and applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

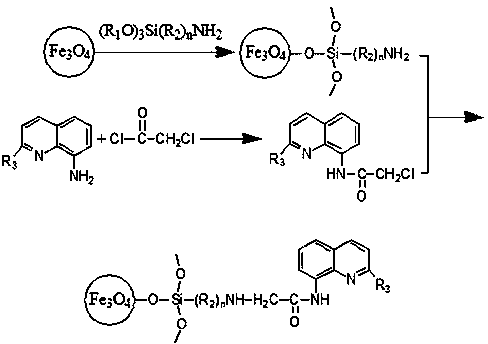

[0028] Embodiment 1: this surface functionalized Fe 3 o 4 The preparation method of nanoparticles comprises the following steps:

[0029] 1. Preparation of magnetic Fe3O4 nanoparticles

[0030] Take 2.0244 g FeCl 2 4H 2 O and 5.3904 g FeCl 3 ·6H 2 O was dissolved in 150 ml of distilled water, and under the condition of nitrogen protection, 55 ml of ammonia water was added dropwise with a constant pressure funnel at a rate of 5 ml / min, heated in a water bath at 65°C and stirred for 2 h, stopped heating, cooled naturally for 30 min, and distilled water , absolute ethanol, and toluene for 3 times, and vacuum-dried for 12 h to obtain magnetic Fe with uniform particle size distribution 3 o 4 Nanoparticles.

[0031] 2. Synthesis of 8-chloroacetylaminoquinoline derivatives

[0032] Take 0.95 g of 8-aminoquinoline in a round bottom flask, add 1 ml of triethylamine, then add 50 ml of dichloromethane solution, keep at 0°C for 30 min; Under light conditions, magnetic stirring...

Embodiment 2

[0041] Embodiment 2: this surface functionalized Fe 3 o 4 The preparation method of nanoparticles comprises the following steps:

[0042] 1. Preparation of magnetic Fe3O4 nanoparticles

[0043] Take 0.2 g FeCl 2 4H 2 O and 0.54 g FeCl 3 ·6H 2 O was dissolved in 50 ml of distilled water, and under the condition of nitrogen protection, 5.5 ml of ammonia water was added dropwise with a constant pressure funnel at a rate of 1 ml / min, heated in a water bath at 40°C and stirred for 6 h, then stopped heating, cooled naturally for 20 min, and then used distilled water, After washing with absolute ethanol and toluene for 3 times, and vacuum drying for 1 h, magnetic Fe with uniform particle size distribution was obtained. 3 o 4 Nanoparticles.

[0044] 2. Synthesis of 8-chloroacetylaminoquinoline derivatives

[0045] Take 0.095 g of 8-amino-2-ethylquinoline in a round bottom flask, add 0.1 ml of triethylamine, then add 5 ml of dichloromethane solution, keep at 0°C for 10 min; ...

Embodiment 3

[0053] Embodiment 3: this surface functionalized Fe 3 o 4 The preparation method of nanoparticles comprises the following steps:

[0054] 1. Preparation of magnetic Fe3O4 nanoparticles

[0055] Take 20g FeCl 2 4H 2 O and 54 g FeCl 3 ·6H 2 O was dissolved in 300 ml of distilled water, and under the condition of nitrogen protection, 100 ml of ammonia water was added dropwise with a constant pressure funnel at a rate of 10 ml / min, heated in a water bath at 90°C and stirred for 1 h, then stopped heating, cooled naturally for 60 min, and distilled water , absolute ethanol, and toluene for 3 times, and vacuum-dried for 24 h to obtain magnetic Fe with uniform particle size distribution. 3 o 4 Nanoparticles.

[0056] 2. Synthesis of 8-chloroacetylaminoquinoline derivatives

[0057] Take 9.5 g of 8-amino-2-methylquinoline in a round bottom flask, add 10 ml of triethylamine, then add 500 ml of dichloromethane solution, keep at 0°C for 60 min; then add 6 ml of chloroacetyl chl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com