Method for removing C4 through rectification and hydrogenation coupling in cracked C5 separation process

A technology of cracking carbon and decarbonizing four towers, which is applied in the field of rectification and hydrogenation coupling to remove carbon four, can solve problems such as the loss of carbon five fractions, increased consumption of resin polymerization catalysts, and the failure of normal operation of the four decarbonizing towers. The effect of reducing the content, avoiding adverse effects, and improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

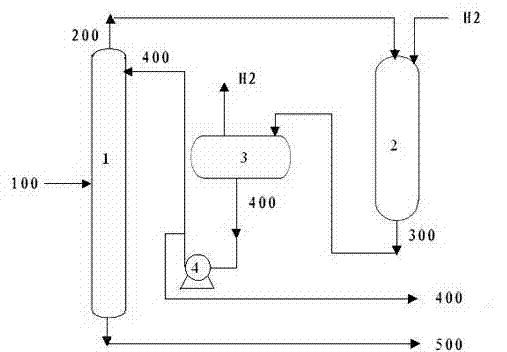

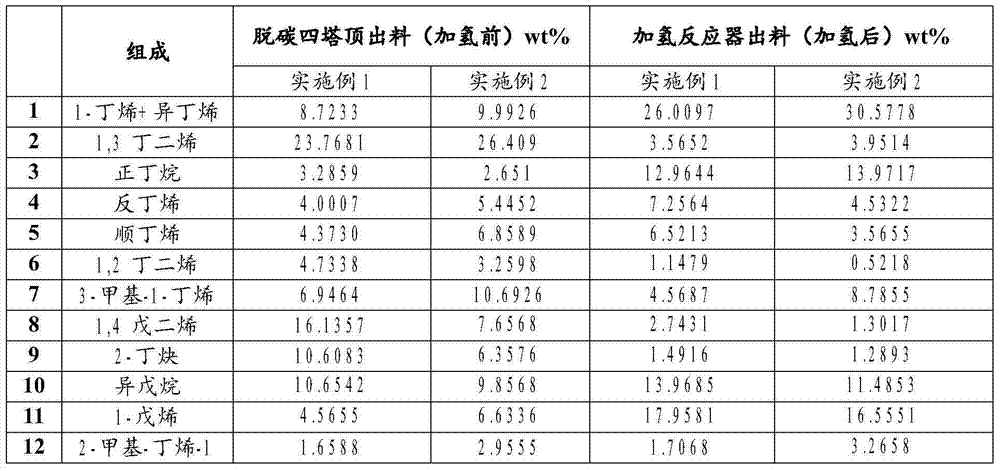

[0024] Such as figure 1 As shown, the specific steps of the method of adopting rectification and hydrogenation coupling to remove carbon four in the cracking carbon five separation process are: 1) the carbon five fraction 100 enters the decarburization four tower 1, and the theoretical plate number of the decarburization four tower 1 70, the temperature at the top of the tower is 55°C, the temperature at the bottom of the tower is 70-90°C, the pressure at the top of the tower is 0.1-0.2MPa, the pressure at the bottom of the tower is 0.2-0.3MPa, the reflux ratio is 12, and the feed is from the middle and upper parts. After being treated in the decarbonization tower 1, the light components 200 containing carbon four hydrocarbons such as butadiene, alkynes and alkanes removed from the top of the tower enter the hydrogenation reactor 2 for selective hydrogenation treatment. The selective hydrogenation reaction uses LY-9801F palladium catalyst, the catalyst bed height-to-diameter r...

Embodiment 2

[0028] Such as figure 1 As shown, the specific steps of the method of adopting rectification and hydrogenation coupling to remove carbon four in the cracking carbon five separation process are: 1) the carbon five fraction 100 enters the decarburization four tower 1, and the theoretical plate number of the decarburization four tower 1 is 100, the temperature at the top of the tower is 45°C, the temperature at the bottom of the tower is 90°C, the pressure at the top of the tower is 0.3MPa, the pressure at the bottom of the tower is 0.4MPa, the reflux ratio is 17, and the feed is from the upper part. After being treated in the decarburization tower 1, the C4 light components 200 including butadiene, alkynes and alkanes removed from the top of the tower enter the hydrogenation reactor 2 for selective hydrogenation treatment. The selective hydrogenation reaction uses HTC200 nickel-based catalyst, the catalyst bed height-to-diameter ratio is 8:1, the reaction pressure is 0.5-1.5MPa,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com