Polyphenylene sulfide paper and preparation method thereof

A technology of polyphenylene sulfide and polyphenylene sulfide resin, applied in the field of papermaking, to achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

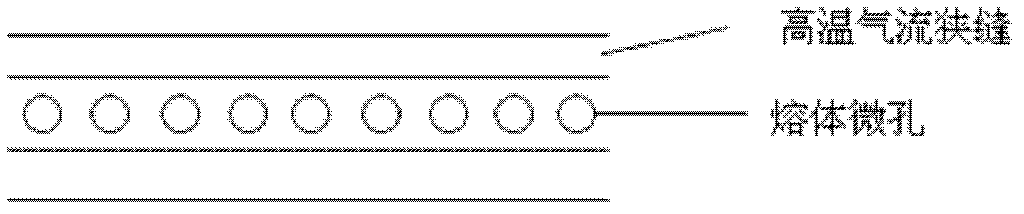

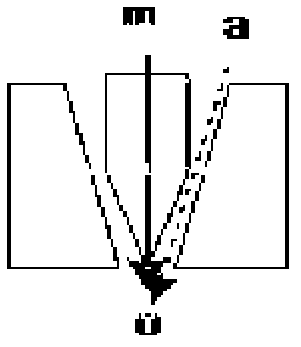

[0027] In the preparation method provided by the present invention, the temperature of the high-temperature air flow is 300-380°C, preferably 340-370°C, the pressure of the high-temperature air flow is controlled at 2.0-3.5bar, and the flow rate is controlled at 13-25m 3 / / hr. Controlling the high-temperature air flow within this range can facilitate the ejection of polyphenylene sulfide in the molten state from the melt-blown die head, and polyphenylene sulfide can maintain good fluidity within this range, thereby reducing the risk of fiber breakage situation, or the situation of insufficient drafting. Of course, those skilled in the art can fully adjust the temperature, pressure and flow rate of the air according to the actual work requirements, so as to control the size of the sprayed polyphenylene sulfide melt stream.

[0028] After the polyphenylene sulfide resin in the molten state is added to the melt-blown die head, under the action of high-temperature air flow, it is...

Embodiment 1

[0042] The pretreatment method of polyphenylene sulfide resin: put the raw material of resin chips into the vacuum drum, and after the vacuum degree is less than 100Pa, raise the temperature to 80°C for two hours of pre-crystallization process, then raise the temperature of the drum to 130°C, keep 10 hours for drying. The moisture content of the dried resin chips is less than 30ppm.

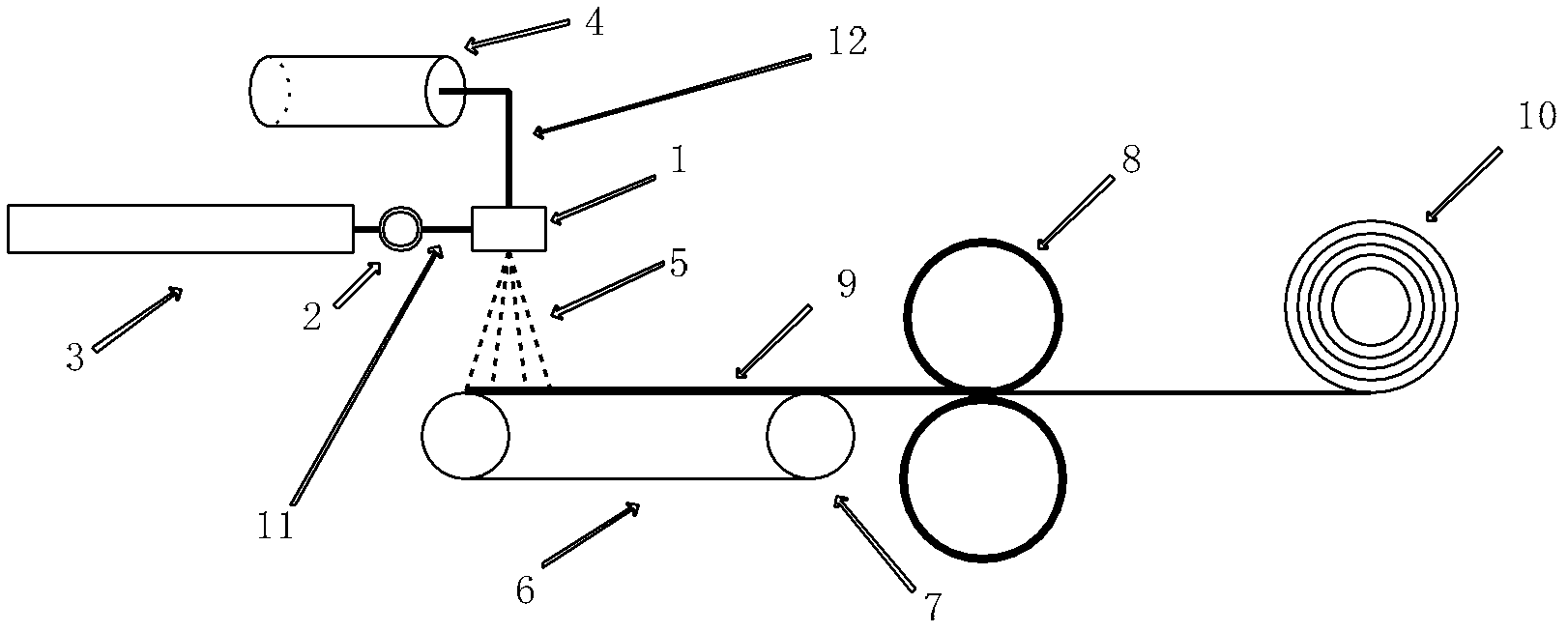

[0043] figure 1 A schematic flow chart of the polyphenylene sulfide melt-blown paper process of this embodiment is shown. Put the pretreated polyphenylene sulfide into the screw extruder 3, the temperature settings of the four heating zones of the screw extruder 3 are 285°C, 310°C, 320°C, 320°C respectively, and the melt passes through the melt The melt pipeline 11 of the metering pump 2 is delivered to the melt-blown die head 1, and the temperature of the melt metering pump 2 and the melt-blown die head 1 is set to 340°C; The high-temperature compressed air flow is conveyed in the injection d...

Embodiment 2

[0047] The pretreatment method of polyphenylene sulfide resin is the same as that of Example 1.

[0048] The difference from Example 1 is that the temperature of the high-temperature air flow is controlled at about 320°C, the pressure of the compressed air is 2.0bar, and the air flow rate is controlled at 20-23m 3 / hr. The spinneret microholes of the meltblown die head are arranged in a line, the diameter of the microholes is 0.35mm, the aspect ratio of the microholes is 7 / 1, and the center distance of the microholes is 1.5mm. The angle between the direction of melt flow and the direction of high temperature air flow is 60°

[0049] The polyphenylene sulfide paper product is obtained after the above processes of melt extrusion, jet forming and hot pressing.

[0050] Cut the above-mentioned melt-blown paper into 20cm×5cm sample strips along the longitudinal and transverse directions (longitudinal is the direction in which the transmission grid travels, and transverse is the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com