Method and device for detecting pressure of laser shock wave

A technology of laser shock and shock wave, applied in the direction of measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of increased measurement cost, damage of measuring devices, high equipment requirements, etc., and achieves convenient operation, simple device and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

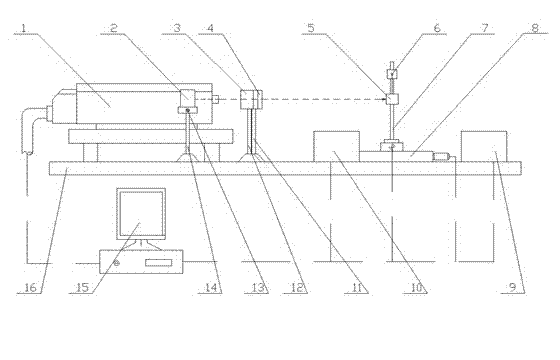

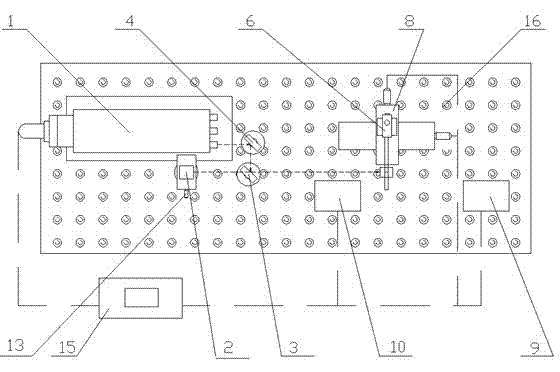

Image

Examples

Embodiment 2

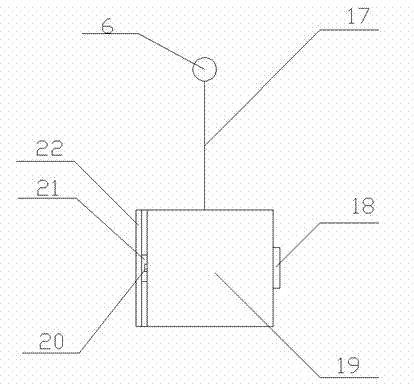

[0033] Using the principle and device of the present invention to carry out a single point on 2024 aluminum alloy, using the PVDF strain gauge 20 and the oscilloscope 10 to measure the laser shock wave pressure action time is 15 μs, and the angle measuring instrument 9 and the acceleration sensor 18 measure the pendulum swing angle to be 16.60° According to the law of energy conservation and momentum theorem, the average force during the laser shock wave action is 7878.37N, and the pressure calculation formula is 1.11GPa.

[0034] The specific experimental conditions are: the length of the thin metal wire 17 is 15 cm, the total mass of the pendulum 5 (sample, PVDF and acceleration sensor) is 337.5 grams, Gaia-R series high-energy pulsed lamp-pumped YAG laser, laser energy 1J, shock The spot diameter is 3mm, the laser wavelength is 1064nm, and the pulse width is 10ns. According to the relationship between laser energy and power density, the corresponding laser power densit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com