Photosensitive benzocyclobutene resin compound and preparation method thereof as well as patterning method thereof

A technology of benzocyclobutene and resin composition, which is applied in the field of photosensitive benzocyclobutene resin composition and preparation, can solve the problems of non-photosensitivity, complicated photolithography process, and increased cost, and achieve cost reduction, The method is simple and convenient, and the film-forming effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

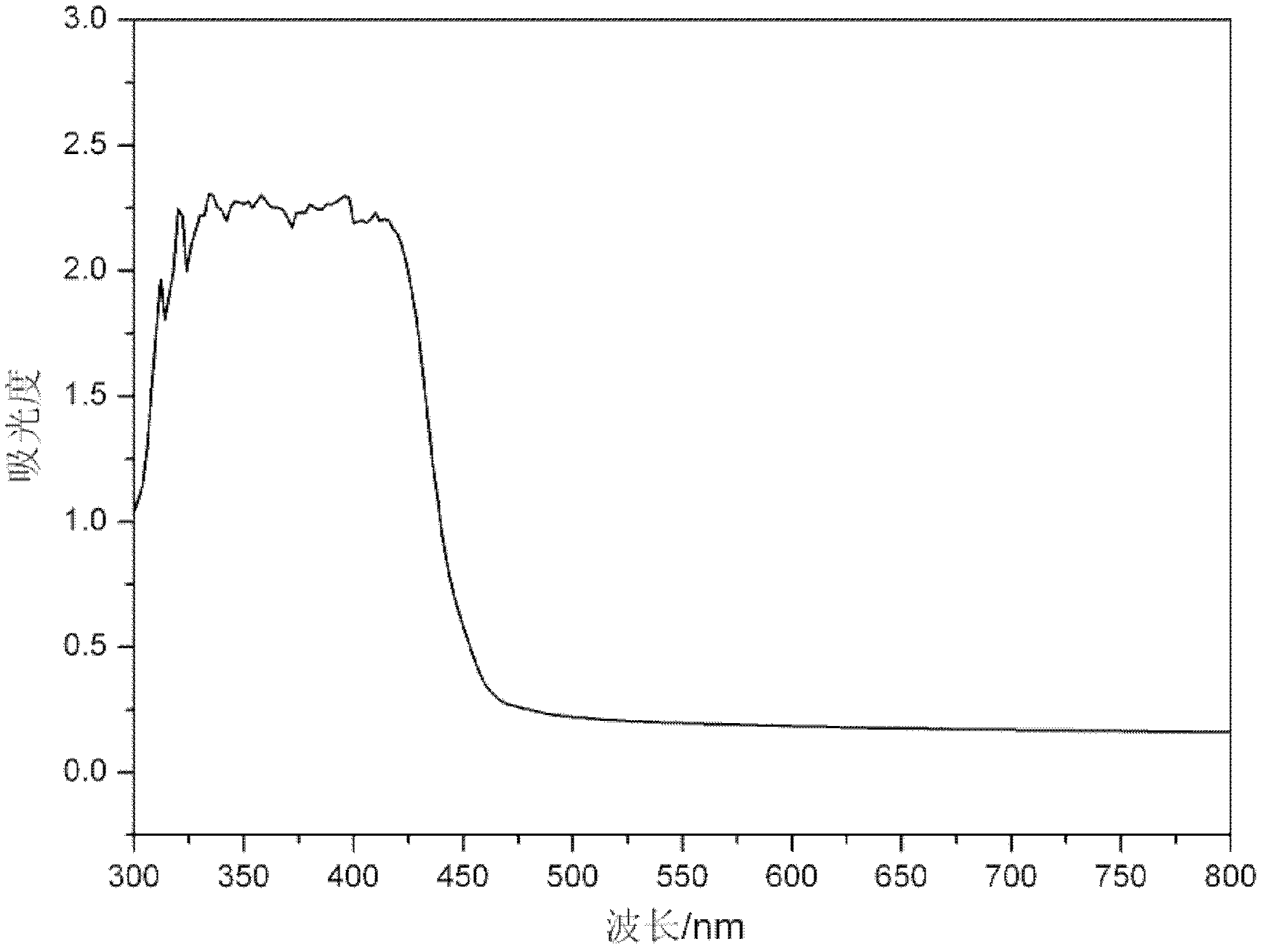

[0076] In a dark room, add 0.15g of benzocyclobutene resin and 2.5g of organic solvent into a 10mL brown bottle, and stir magnetically at room temperature for 30 minutes; then add 0.016g of photosensitizer to the system, continue to stir for 2 hours and then A negative photosensitive BCB resin composition with a mass fraction of about 25% was obtained, and the appearance of the composition was orange-yellow transparent liquid. Wherein, the structural formula of the benzocyclobutene resin is Among them, R is CO;

[0077] The photosensitizer is ultraviolet photosensitizer BAC-M, and the organic solvent is dichloromethane.

Embodiment 2

[0079] In a dark room, add 0.16g of benzocyclobutene resin and 2.3g of organic solvent into a 10mL brown bottle, and stir magnetically at room temperature for 60 minutes; then add 0.05g of photosensitizer to the system, and continue stirring for 5 hours. A negative photosensitive BCB resin composition with a mass fraction of about 8.7% was obtained, and the appearance of the composition was an orange-yellow transparent liquid. Wherein, the structural formula of the benzocyclobutene resin is Among them, R is CO;

[0080] The photosensitizer is ultraviolet photosensitizer BAC-M, and the organic solvent is dichloromethane.

Embodiment 3

[0082] In a dark room, add 0.06g of benzocyclobutene resin and 0.42g of organic solvent into a 5mL brown bottle, and stir magnetically at room temperature for 30 minutes; then add 0.0076g of photosensitizer to the system, continue stirring for 1 hour A negative photosensitive BCB resin composition with a mass fraction of about 13% was obtained, and the appearance of the composition was an orange-yellow transparent liquid. Wherein, the structural formula of the benzocyclobutene resin is Among them, R is C(CF 3 ) 2 ;

[0083] The photosensitizer is ultraviolet photosensitizer BAC-M, and the organic solvent is dichloromethane.

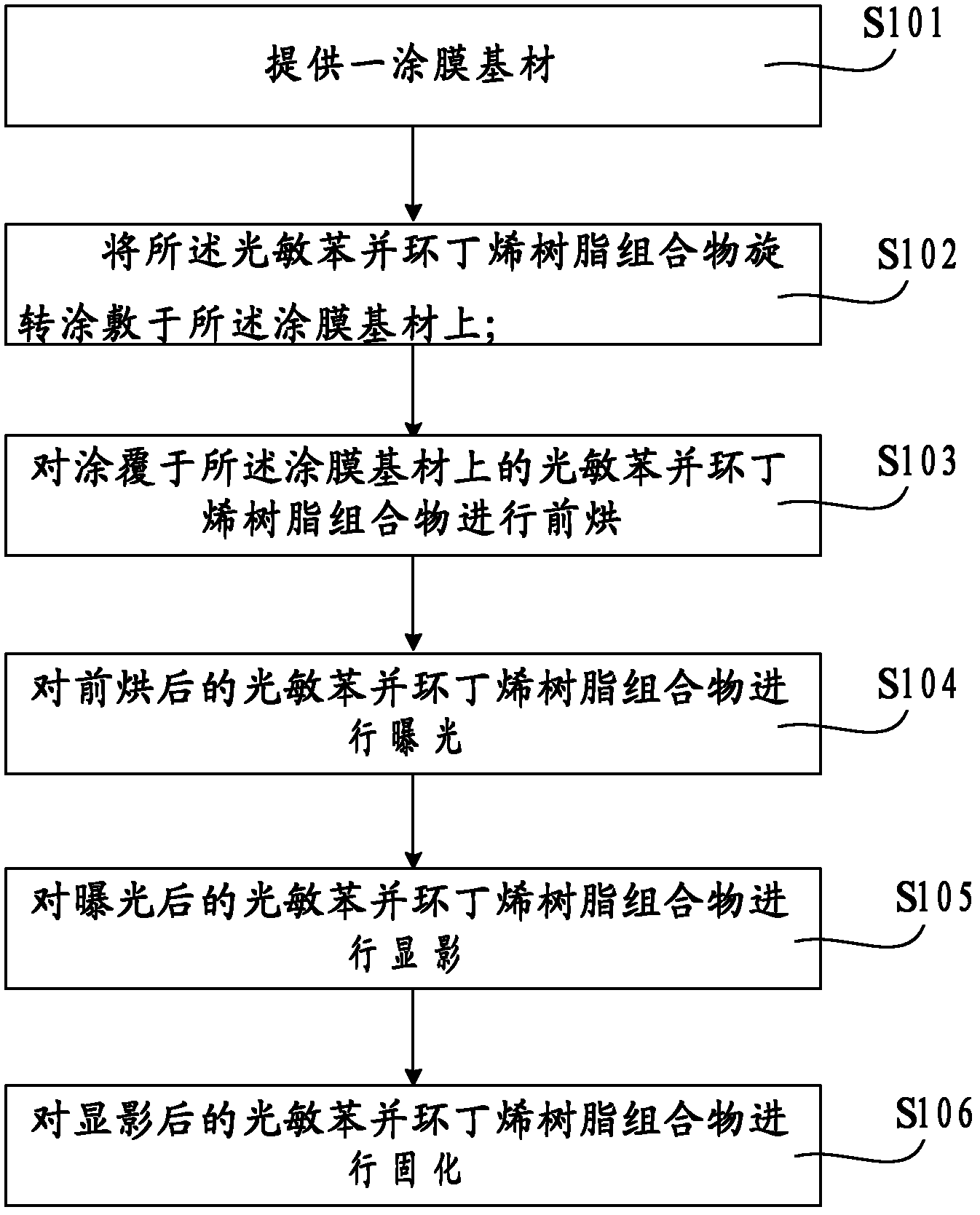

[0084] Please refer to figure 2 ,as well as Figure 3A to Figure 3E ,in figure 2 The flowchart of the patterning method of the photosensitive benzocyclobutene resin composition provided by the embodiment of the present invention, Figure 3A to Figure 3E The schematic diagram of the device structure corresponding to each step of the patterning me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com