Anomalous plane hollow microneedle based on surface micro processing process and preparation method thereof

A microfabrication and hollow microtechnology, which is applied in the direction of microneedles, needles, medical devices, etc., can solve the problems of complex and cumbersome steps, unfavorable mass production, and height restrictions of microneedles, and achieve simple and easy process and rapid replication And the effect of high-speed mass production, wet etching and simple operation of casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

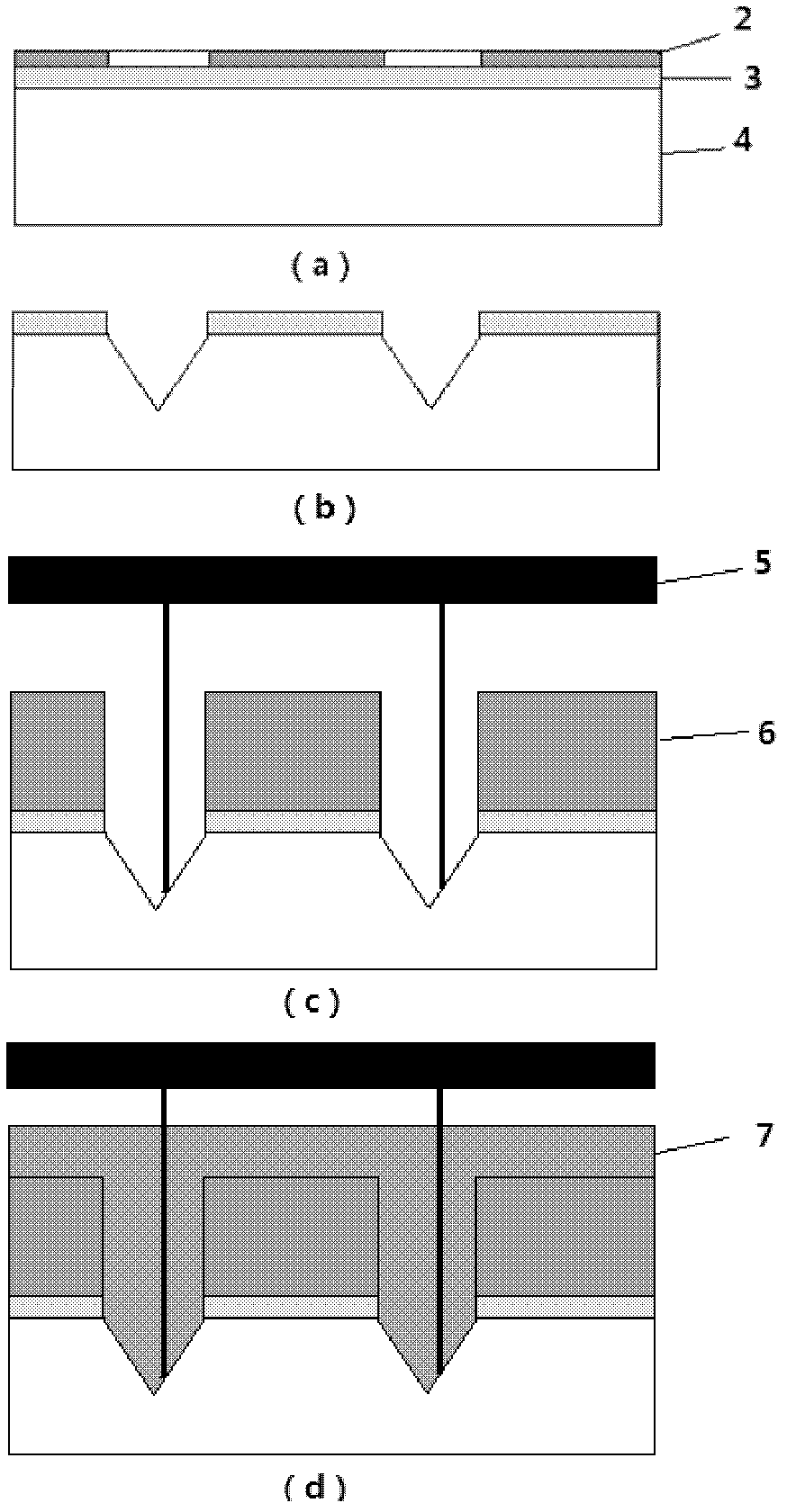

[0025] Such as figure 2 As shown, this embodiment includes the following steps:

[0026] Step 1: Prepare a p-type boron-doped polished wafer 4 with crystal orientation as a substrate. A layer of positive resist 2 with a thickness of 5 μm is thrown on it, and developed by photolithography, and the mask plate has a square pattern.

[0027] The second step: using HF wet etching process to remove the silicon oxide 3 at the part not covered by the positive resist.

[0028] Step 3: Etching the silicon wafer treated in the second step with KOH with a mass fraction of 30% to obtain an inverted quadrangular pyramid structure.

[0029] Step 4: Throw a layer of SU-8 glue 6 with a thickness of 300 μm, and develop it by photolithography. The mask plate has a circular structure.

[0030] Step 5: Load the molybdenum wire array plate 5 into the obtained concave mold. The molybdenum wire array is obtained by performing photolithography, development and electroplating on the photoresist, a...

Embodiment 2

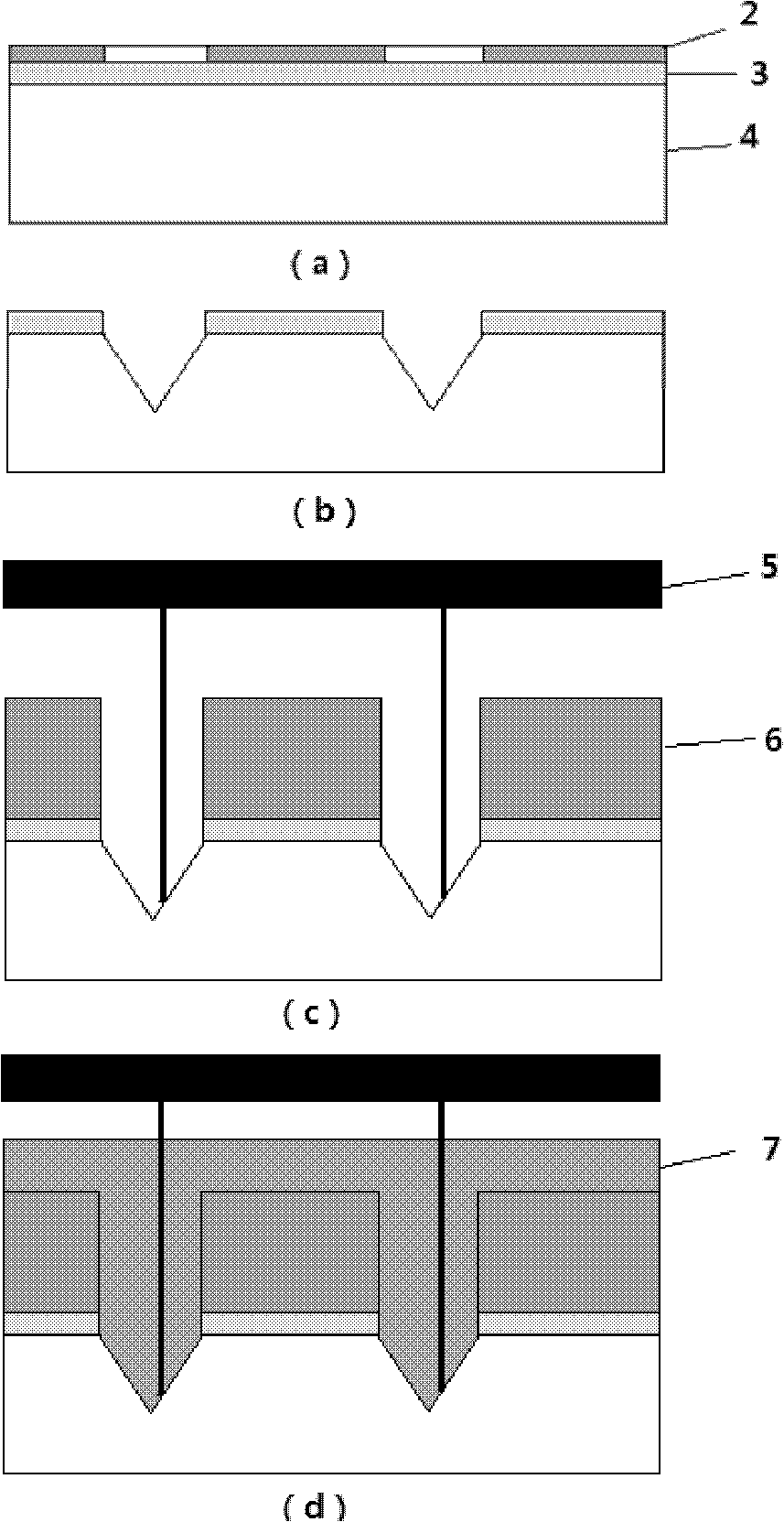

[0034] Such as figure 2 As shown, this embodiment includes the following steps:

[0035] Step 1: Prepare a p-type boron-doped polished wafer 4 with crystal orientation as a substrate. A layer of positive resist 2 with a thickness of 5 μm is thrown on it, and developed by photolithography, and the mask plate has a square pattern.

[0036] The second step: using HF wet etching process to remove the silicon oxide 3 at the part not covered by the positive resist.

[0037] Step 3: Etching the silicon wafer treated in the second step with KOH with a mass fraction of 30% to obtain an inverted quadrangular pyramid structure.

[0038] Step 4: Throw a layer of SU-8 glue 6 with a thickness of 200 μm, and develop it by photolithography. The mask plate has a circular structure.

[0039] Step 5: Load the molybdenum wire array plate 5 into the obtained concave mold. The molybdenum wire array is obtained by performing photolithography, development and electroplating on the photoresist, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com