High-efficiency nano Pd catalyst used in the process of preparing oxalate through CO carbonylation and prepared by dipping-controllable reduction method

A catalyst and reducing agent technology, applied in the field of high-efficiency nano-Pd catalysts, can solve the problems of active component crystallite coalescence, catalytic activity reduction, and high dispersion of active groups, and achieve simple preparation process, low cost, and industrialization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

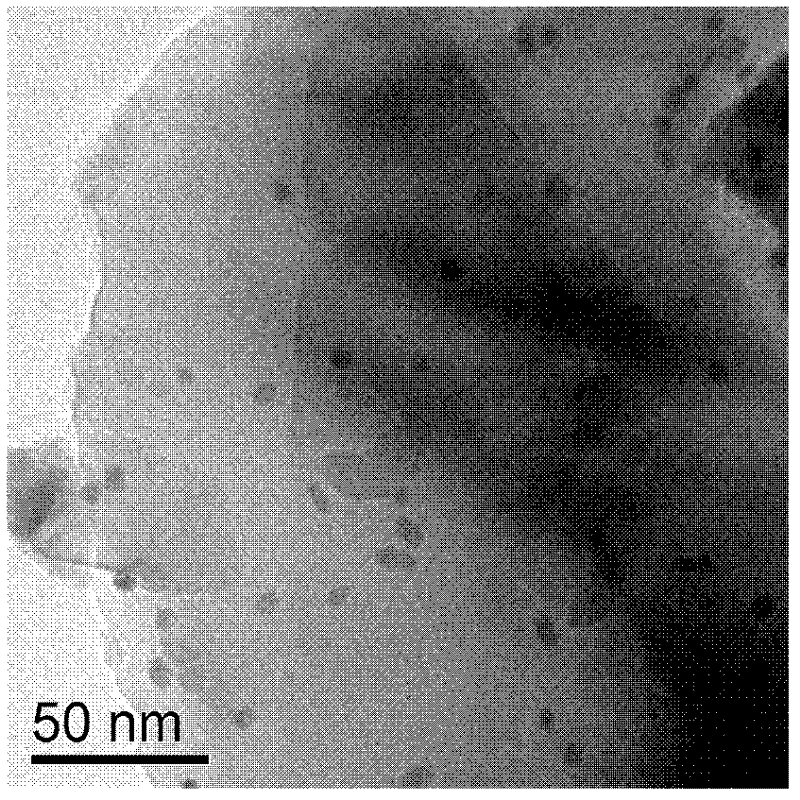

[0044] Weigh 1g of α-alumina and impregnate it into 1.25mL of 37.6mmol / L K 2 PdCl 4- Add 4 mL of ethanol to the aqueous solution, stir for 3 hours, ultrasonically disperse in a 40°C water bath with 200W energy for 4 hours, dry at 110°C for 4 hours, and roast at 400°C for 4 hours, add 0.070g ascorbic acid, 0.353g KBr, and 0.444g PVP , reduced at 100°C for 30 minutes, and dried in vacuum at 60°C for 10 hours. TEM photo see figure 1 , it can be seen from the figure that Pd is evenly dispersed on the surface of the carrier, and the particles are mainly spherical, with a small amount of irregular polyhedron, and the average size is 6–7nm.

[0045] Catalyst evaluation: The catalyst in the examples of the present invention was applied to the gas-phase carbonylation of CO to produce oxalate, the catalyst dosage was 1 mL, and the N in the raw gas 2 : CO: RONO = 48: 28: 20 (volume ratio), gas phase space velocity is 3000h -1 , the reaction temperature is 130°C, the reaction pressure...

Embodiment 2

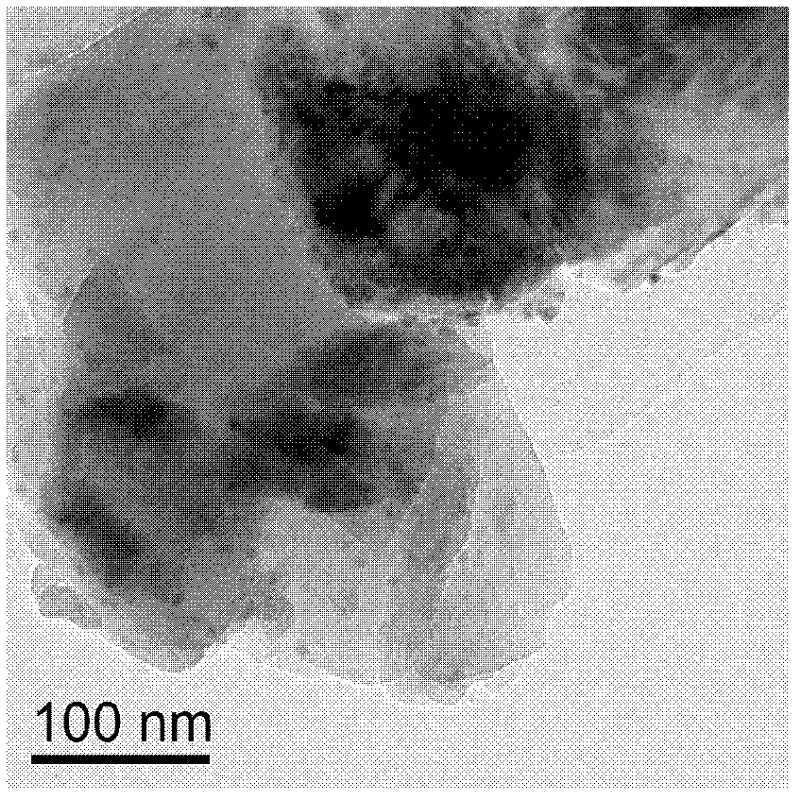

[0047] Weigh 1g of α-alumina and impregnate it into 1.25mL of 37.6mmol / L Pd(NO 3 ) 2- Add 4 mL of acetone to the aqueous solution, stir for 3 hours, ultrasonically disperse in a 35°C water bath with 200W energy for 3 hours, dry at 110°C for 4 hours, and roast at 400°C for 4 hours, add 0.105g citric acid, 0.353g KBr, 0.444g PVP was reduced at 90°C for 15 hours, then 0.018g of ascorbic acid was added to continue the reduction at 90°C for 30 minutes, and then dried in vacuum at 60°C for 10 hours. TEM photo see figure 2 , it can be seen from the figure that Pd is evenly dispersed on the surface of the carrier, and the particles are mainly spherical, with a small amount of irregular polyhedrons, and the average size is 4–6 nm. For chromatographic analysis see Figure 6 , and the reaction results are shown in Table 1.

Embodiment 3

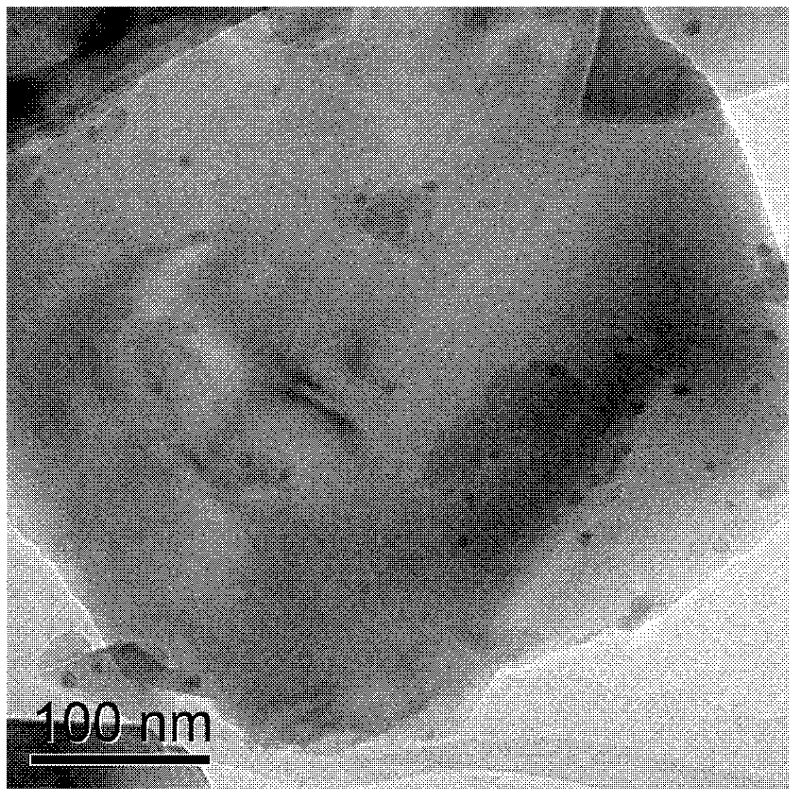

[0049] Weigh 1g of α-alumina and impregnate it into 1.25mL of 37.6mmol / L Pd(OAc) 2- Add 4 mL of acetone to the acetone solution, stir for 3 hours, ultrasonically disperse in a 35°C water bath with 200W energy for 3 hours, dry at 110°C for 4 hours, bake at 400°C for 2 hours, add 0.070g of ascorbic acid, 0.353g of KBr, 0.444g For PVP, reduce at 100°C for 30 minutes, and dry at 60°C for 10 hours under vacuum. TEM photo see image 3 , it can be seen from the figure that Pd is evenly dispersed on the surface of the carrier, and the particles are mainly spherical, with a small amount of irregular polyhedrons, and the average size is 4–6 nm. For chromatographic analysis see Figure 7 , and the reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com