Tellurium semiconductor micro-nanometer crystal and preparation method

A micro-nano, semiconductor technology, applied in the field of micro-nano crystals and their preparation, can solve the problems of difficult preparation of three-dimensional superstructure semiconductor micro-nano materials, and achieve the effects of low cost, safe and simple operation, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

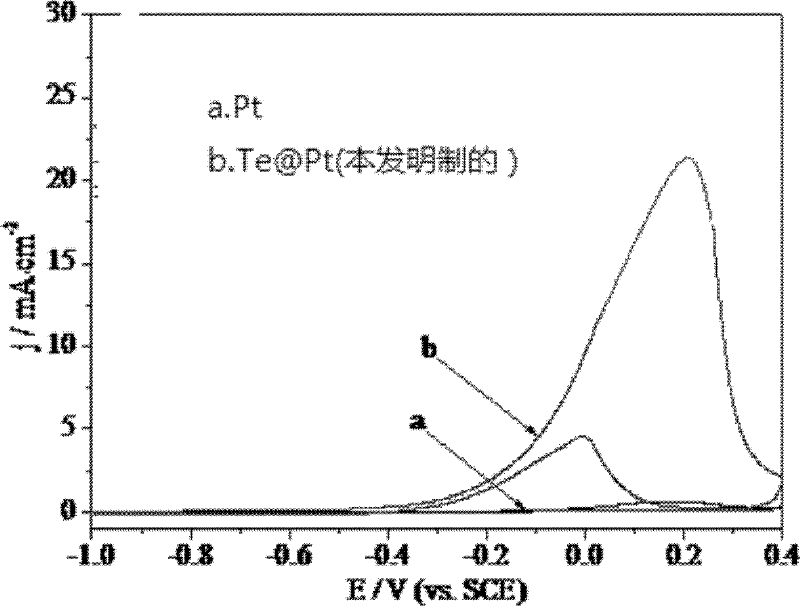

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

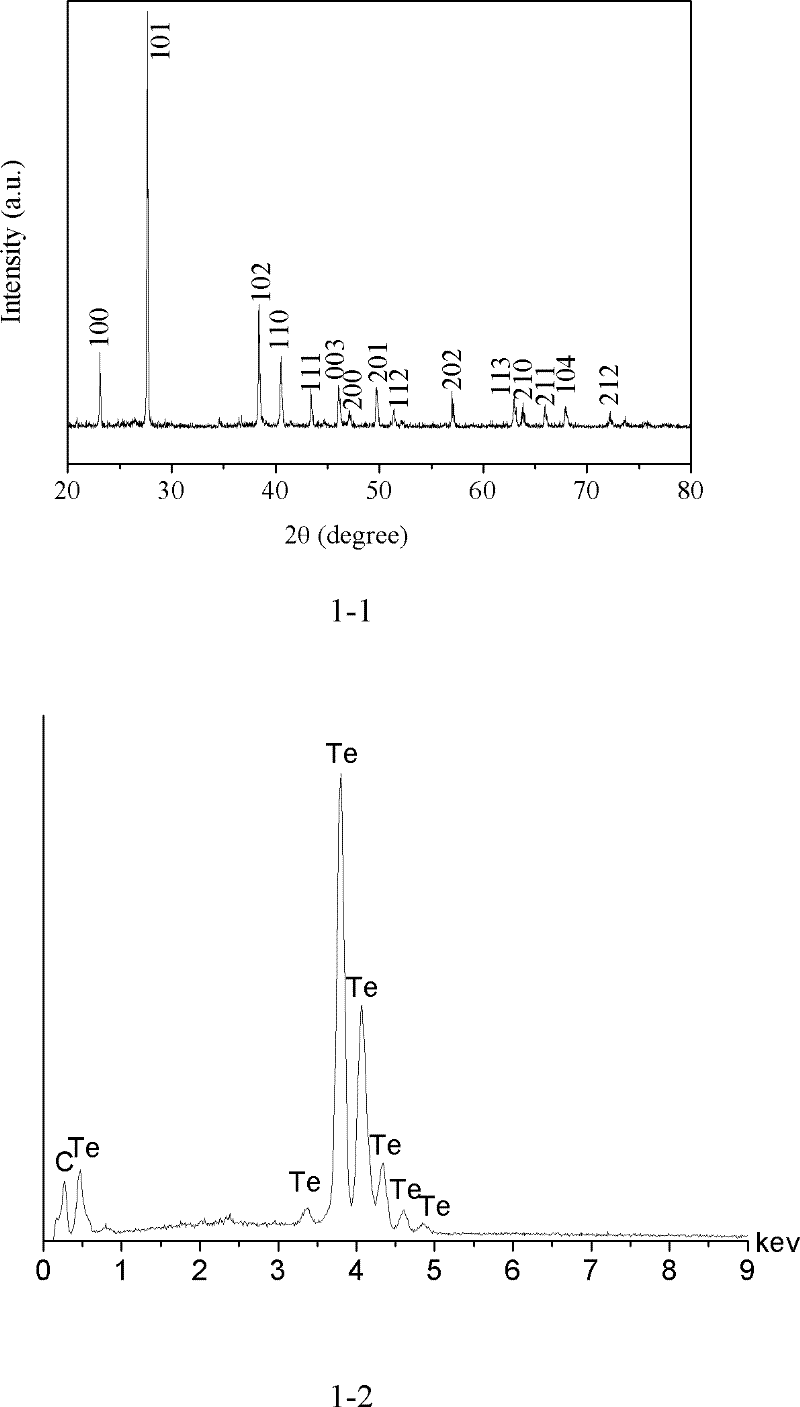

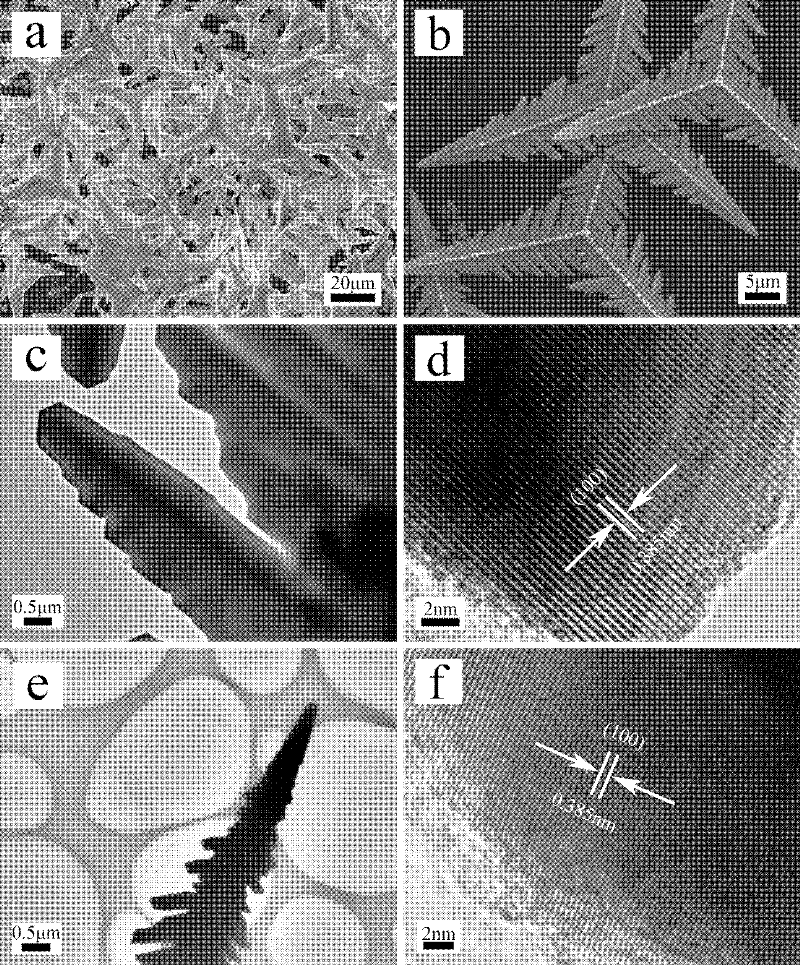

Embodiment 1

[0025] In a 100ml stainless steel autoclave lined with polytetrafluoroethylene, weigh 0.6mmol (0.43g) of tellurium diethyldithiocarbamate and add it to 20ml of chloroform, then add 1.2mmol of dithiosalicylic acid and 30ml Anhydrous ethanol, after sealing the autoclave, place it at a temperature of 110°C, and react under a pressure of 1.5MPa for 10 hours, then cool the reaction solution to room temperature (25°C), put the reaction solution in a separatory funnel and let it stand for stratification , take the two-phase interface product and centrifuge to obtain a precipitate, that is, a black solid product. The precipitate is washed with high-purity water and absolute ethanol in sequence, and repeated 3 times. The washing solution is filtered, and the filter cake is dried in a vacuum oven for 20 hours to obtain a three-dimensional three-branch Tellurium semiconductor micro-nanocrystals with dendrite morphology 0.5mmol (calculated by the amount of tellurium substance, the same bel...

Embodiment 2

[0027]In a 100ml stainless steel autoclave lined with polytetrafluoroethylene, weigh 0.3mmol (0.122g) of diphenyl tellurium and 0.3mmol (0.11g) of di-tert-butyl tellurium, add 10ml of chloroform and 10ml of carbon disulfide, and then Add 0.6mmol of dithiosalicylic acid and 20ml of absolute ethanol, seal the autoclave and place it at a temperature of 140°C, react under 1MPa pressure for 5 hours, cool to room temperature, and place the reaction solution in a liquid separation Stand in the funnel for stratification, take the two-phase interface product and centrifuge to obtain a precipitate, that is, a black solid product. The precipitate is washed with high-purity water and absolute ethanol for 3 times, and the washing solution is filtered. The filter cake is dried in a vacuum oven. After 20 hours, 1.1 mmol of tellurium semiconductor micro-nanocrystals with three-dimensional three-dendrite morphology were obtained.

Embodiment 3

[0029] In a 100ml stainless steel autoclave lined with polytetrafluoroethylene, weigh 0.6mmol (0.133g) of sodium tellurite, add it to 15ml of chloroform, then add 0.4mmol of citric acid and 0.2mmol of dithiosalicylic acid and 30ml of absolute ethanol, the autoclave was sealed and placed at a temperature of 120°C, and reacted for 15 hours under a pressure of 1.2MPa. After cooling to room temperature, the reaction solution was placed in a separatory funnel and allowed to stand for stratification, and the two-phase interface was taken. The product was centrifuged to obtain a precipitate, that is, a black solid product. The precipitate was washed with high-purity water and absolute ethanol in sequence, and repeated 3 times. The washing liquid was filtered, and the filter cake was dried in a vacuum drying oven for 10 hours to obtain a three-dimensional tridendritic form of tellurium Semiconductor micro-nano crystal 0.48mmol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com