Method for synergetically treating fluorine-containing sludge in cement kiln

A co-processing, cement kiln technology, applied in the field of environmental protection and sludge treatment, can solve the problems of small processing capacity, high processing cost and high energy consumption, and achieve the effects of long residence time, production cost saving and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

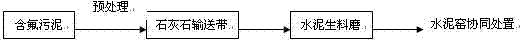

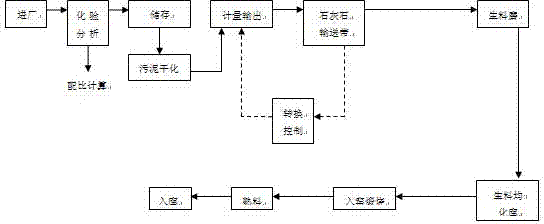

Method used

Image

Examples

Embodiment 1

[0034] In the new dry-process cement clinker production line with a daily output of 2,500 tons, the cement raw materials are accurately measured according to the weight ratio of limestone: sand shale: copper slag = 80.0:15.6:4.4, and then are transported by the belt into the raw cement mill, and the waste heat of the cement kiln is used. The tail gas is dried and pretreated with fluorine-containing sludge with a moisture content of 60% by a disc dryer, and the moisture content is ≤30%, and then transported to the limestone conveyor belt by a metering conveyor belt, mixed and homogenized with limestone and added to the cement raw meal mill. Add 1.67 tons of the above-mentioned fluorine-containing sludge per hour (converted to about 1% of the wet fluoride-containing sludge in the cement raw material). Cement raw meal is homogenized and sent to the calcination system to be fired into cement clinker. The ratio of cement clinker is: lime saturation ratio (KH) = 0.920, silicic aci...

Embodiment 2

[0036] In the 2,500-ton new dry-process cement clinker production line, it is accurately measured according to limestone:sand shale:copper slag=80.0:15.6:4.4 (weight ratio), and then it is conveyed by belt into the cement raw material mill, and the waste heat exhaust gas from the cement kiln is used. The disc dryer dries the fluorine-containing sludge with a moisture content of 60% and pre-treats it with a moisture content of ≤30%, and then uses a metering conveyor belt to transport it to the limestone conveyor belt, mix and homogenize it with limestone and add it to the cement raw meal mill. The amount of sludge is 8.33 tons (converted to about 5% of the wet fluorine-containing sludge in the cement raw material). The fluorine-containing sludge is dried in the raw cement mill by using the waste heat of the rotary kiln exhaust gas, and mixed with the cement raw material. Grind together into cement raw meal, after homogenization, send it to the calcination system, and burn it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com