Method for synthetizing DL-cysteine

A synthesis method and cysteine technology are applied in the synthesis field of DL-cysteine, can solve the problems of high production cost, complicated process, low yield and the like, and achieve low production cost, high reaction yield, and high production efficiency. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

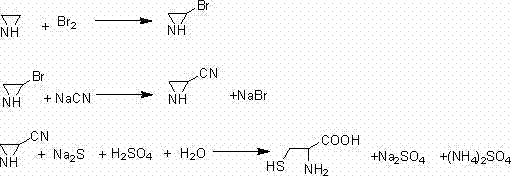

[0021] A synthetic method for DL-cysteine, comprising the steps of:

[0022] (1) Using ethyleneimine to react with bromine water to obtain 2-bromo-ethyleneimine;

[0023] (2) adding cyanide to the 2-bromo-ethyleneimine prepared in step (1) for heat preservation reaction to obtain 2-cyano-ethyleneimine;

[0024] (3) ring-opening reaction of 2-cyano-ethyleneimine prepared in step (2) with sodium sulfide to generate 2-mercapto-3-aminopropylcyanide;

[0025] (4) Acid hydrolysis of 2-mercapto-3-aminopropanil produced in step (3) at 60°C-90°C to obtain DL-cysteine.

[0026] Wherein, in step (1), the molar ratio of ethyleneimine to bromine water is 1:0.8-1.1; the reaction temperature is 0°C-40°C, and the reaction time is 1-6h; the The preferred reaction temperature is 5°C-30°C, and the preferred reaction time is 2-5h.

[0027] In step (2), the molar ratio of 2-bromo-ethyleneimine to sodium cyanide is 1:1-1.1; the reaction temperature is 0°C-80°C, and the reaction time is 2 -5h; t...

Embodiment 1

[0032] Add 43.4g of ethyleneimine into a 500ml flask, control the temperature at 40°C, add 129.3g of bromine water under stirring, and keep the reaction for 4h. Add 50g of sodium cyanide to the flask, keep it warm for 5 hours, control the temperature to 50°C, add 200ml of acetone, continue stirring for 1 hour, remove the sodium bromide by filtration, and use the filtrate for later use. Put 78 g of sodium sulfide and 150 ml of water into a 1000 ml flask, raise the temperature to 55°C, then add the above filtrate dropwise into the sodium sulfide aqueous solution, after the dropwise addition, keep warm for 2 hours, then add 200g of 98% sulfuric acid dropwise. Heat up to 80°C, heat-preserve and hydrolyze for 4 hours, filter to remove inorganic salts, cool the filtrate to 5°C, filter, wash the filter cake with 100ml of acetone, and dry to obtain 83.5g of DL-cysteine with a yield of 68.39%.

Embodiment 2

[0034] Add 43.4g of ethyleneimine into a 500ml flask, control the temperature at 0°C, add 177.8g of bromine water under stirring, and keep the reaction for 1h. Add 55g of sodium cyanide to the flask, keep it warm for 4 hours, control the temperature to 38°C, add 200ml of acetone, continue stirring for 1 hour, remove the sodium bromide by filtration, and use the filtrate for later use. Put 82g of 98% sodium sulfide and 150ml of water into a 1000ml flask, raise the temperature to 60°C, then add the above-mentioned filtrate dropwise into the sodium sulfide aqueous solution, after the dropwise addition, keep warm for 3 hours, then add 200g of 98% sulfuric acid dropwise. Heat up to 80°C, heat-preserve and hydrolyze for 4 hours, filter to remove inorganic salts, cool the filtrate to 5°C, filter, wash the filter cake with 100ml acetone, and dry to obtain DL-cysteine 77g, yield 63.07%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com