Catalyst applied to vinyl polymerization and preparation method and application thereof

An ethylene polymerization and catalyst technology, which is applied to a catalyst for ethylene polymerization and its preparation method and application field, can solve the problems of poor particle shape and distribution, low polymer apparent density, etc., and achieves easy separation, improved activity and The effect of hydrogen modulation sensitivity and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

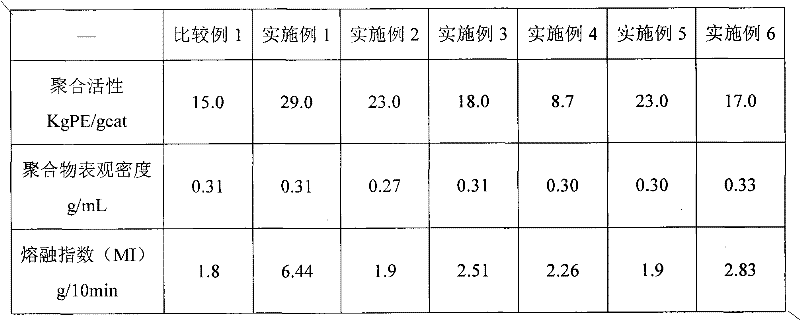

Examples

Embodiment 1

[0042] In the high-purity N 2 In the fully replaced reactor, add 4.0g of anhydrous MgCl successively 2 , 50mL toluene, 2.0mL epichlorohydrin, 3.0mL tributyl phosphate, heat up to 50°C with stirring, and maintain it for 15 minutes, add 6.0mL ethanol, continue the reaction for 15 minutes, and cool the solution to -5~0°C , then drop 30mL of titanium tetrachloride into it, then add 5mL of a mixture of tellurium tetrachloride and ethanol to raise the temperature of the solution to 80°C, filter, wash with hexane four times, and dry in vacuum to obtain a solid catalyst.

[0043] A mixed solution of tellurium tetrachloride and ethanol was prepared by adding 1.56 g of tellurium tetrachloride to 8 mL of ethanol, stirring at 0° C. for 2 hours, stopping the stirring, and standing at room temperature for use.

Embodiment 2

[0045] Same as in Example 1, except that the mixed solution of tellurium tetrachloride and ethanol was changed to 3 mL.

Embodiment 3

[0047] Same as in Example 1, except that the mixed solution of tellurium tetrachloride and ethanol was changed to 1 mL. And the mixture of tellurium tetrachloride and ethanol was prepared by adding 3 grams of tellurium tetrachloride into 3 mL of ethanol, stirring at 0° C. for 2 hours, stopping the stirring, and standing at room temperature for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com