Soluble and ultraviolet-crosslinked-cured polyaryletherketone and preparation method thereof

A technology of polyaryletherketone and cross-linking, which is applied in the field of polymer materials, can solve the problems of single processing method, limited application range, high melting temperature, etc., achieve high heat resistance, improve material processing performance and thermal performance, and improve use The effect of temperature

Inactive Publication Date: 2012-07-04

吉林省聚科高新材料有限公司

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For most polyaryletherketone varieties, due to the rigidity and crystallinity of the molecular chains, the molecular chains are tightly packed, resulting in poor solubility and high melting temperature. Single, which limits its scope of application

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1 to Embodiment 3

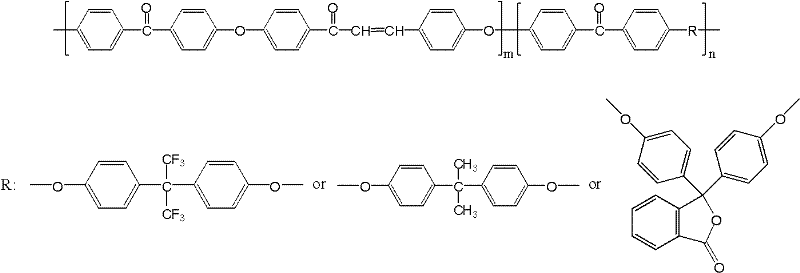

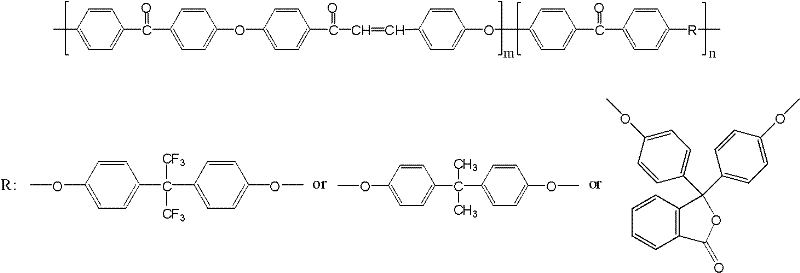

[0015] (1) embodiment 1 to embodiment 3 polymer structural formula

[0016]

Embodiment 4 to Embodiment 6

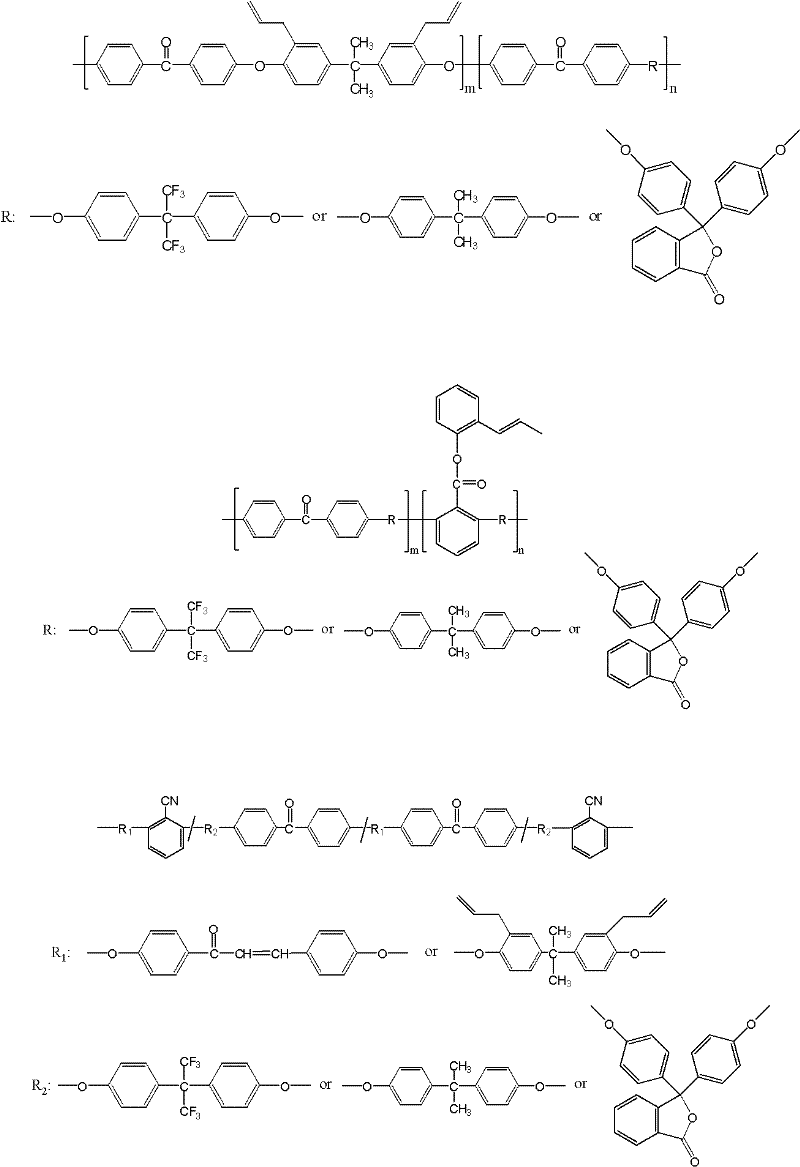

[0017] (II) embodiment 4 to embodiment 6 polymer structure

[0018]

Embodiment 7 to Embodiment 9

[0019] (III) Embodiment 7 to embodiment 9 polymer structure

[0020]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to soluble and ultraviolet-crosslinked-cured polyaryletherketone and a preparation method thereof, belonging to the technical field of high-molecular materials. The preparation method comprises the following steps of: selecting three compounds containing allyl and vinyl structure bisphenol and difluoro monomers such as 4, 4'-dyhydroxyl chalcone, 2, 2'-diene propyl bisphenol A and 2'-allyl phenyl-2, 6-difluoro benzoic acid as crosslinking points, selecting a difluoro monomer compound (4, 4'-difluorobenzophenone, 2, 6-difluorocyanophenyl and difluoro monomer compounds (hexafluorobisphenol A, bisphenol A and phenolphthalein) to prepare a series of polyaryletherketone polymers by a nucleophilic substitution reaction route. Sulfolane or N-methyl pyrrolidone or dimethyl sulfoxide or N, N-dimethylacetylamide is adopted as a solvent, potassium carbonate or sodium carbonate is adopted as a catalyst, and reaction products are dispersed in water, washed with alcohol and water and finally dried for 10-12 hours at the temperature of 100-120 DEG C. The soluble and ultraviolet-crosslinked-cured polyaryletherketone has the beneficial effects of no damage to the materials when carrying out irradiation on the high-molecular materials, has the advantages of high efficiency, energy conservation and simple control method, and is suitable for industrial and large-scale production.

Description

technical field [0001] The invention belongs to the technical field of polymer materials. Background technique [0002] Polyether ether ketone (PEEK), as a fully aromatic semi-crystalline polymer, has excellent physical and chemical properties, so it is widely used in electronic appliances, mechanical instruments, transportation, aerospace and other fields. For most polyaryletherketone varieties, due to the rigidity and crystallinity of the molecular chains, the molecular chains are tightly packed, resulting in poor solubility and high melting temperature. Single, which limits its scope of application. With the different needs of the application purpose and application environment, many researchers focus on improving the processing performance, increasing the heat resistance level and other issues, and constantly develop such new materials with excellent performance to meet different use requirements. For example, introducing different functional groups (such as naphthalen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08G65/40C08J3/28C08J3/24

Inventor 白迪

Owner 吉林省聚科高新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com