End-capped modified polyformaldehyde resin and preparation method thereof

A polyoxymethylene resin and modification technology, which is applied in the field of end-capped modified polyoxymethylene resin and its preparation, can solve the problems of difficult further reduction of end group content and molecular weight reduction, and achieve good end group stabilization effect, end group The effect of reducing content and reducing formaldehyde emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

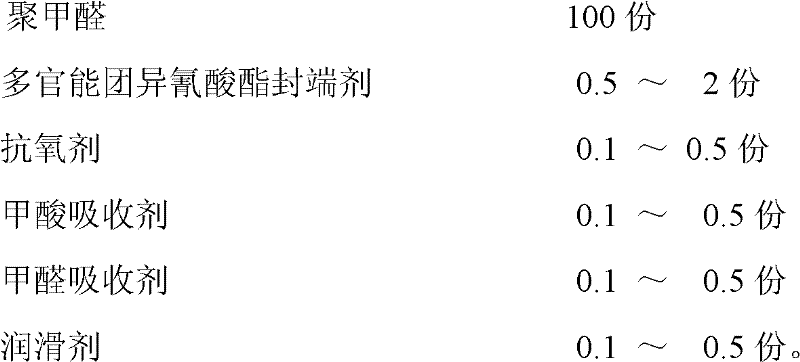

Embodiment 1

[0034] 10Kg of polyoxymethylene powder, 4,4'-diphenylmethane diisocyanate (MDI) 50g, tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester 10g, Calcium stearate 10g, melamine 10g, and glyceryl monostearate 10g are evenly mixed and then melted and extruded by a vented twin-screw extruder. The extrusion temperature is 180°C-220°C, and the screw speed is 100 rpm. After pelleting, dry at 80°C for 3 hours.

Embodiment 2

[0036] Polyoxymethylene powder 10Kg, 4,4'-diphenylmethane diisocyanate (MDI) 100g, β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate 30g, Calcium hydroxide 20g, melamine 30g, polyamide PA610g, glyceryl monostearate 50g are uniformly mixed and then melted and extruded by a vented twin-screw extruder at an extrusion temperature of 180°C to 220°C and a screw speed of 100 rpm After granulation, dry at 80°C for 3 hours.

Embodiment 3

[0038] 10Kg of polyoxymethylene powder, 4,4'-diphenylmethane diisocyanate (MDI) 200g, tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester 50g, β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate 5g, magnesium hydroxide 50g, melamine 50g, bis stearamide 30g are uniformly mixed and then extruded by vented twin-screw Extrusion machine melt extrusion, the extrusion temperature is 180 ℃ ~ 220 ℃, the screw speed is 100 rpm, after granulation, it is dried at 80 ℃ for 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com