Preparation method of thermally-stabilized copolyoxymethylene

A formaldehyde copolymer and heat-stabilized technology, which is applied in the preparation of heat-stable formaldehyde copolymer and end-group stabilization treatment in the post-treatment of formaldehyde copolymer powder, can solve the problem of low production efficiency, difficulty in complete hydrolysis of unstable end-group, and alkaline medium Problems such as large amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

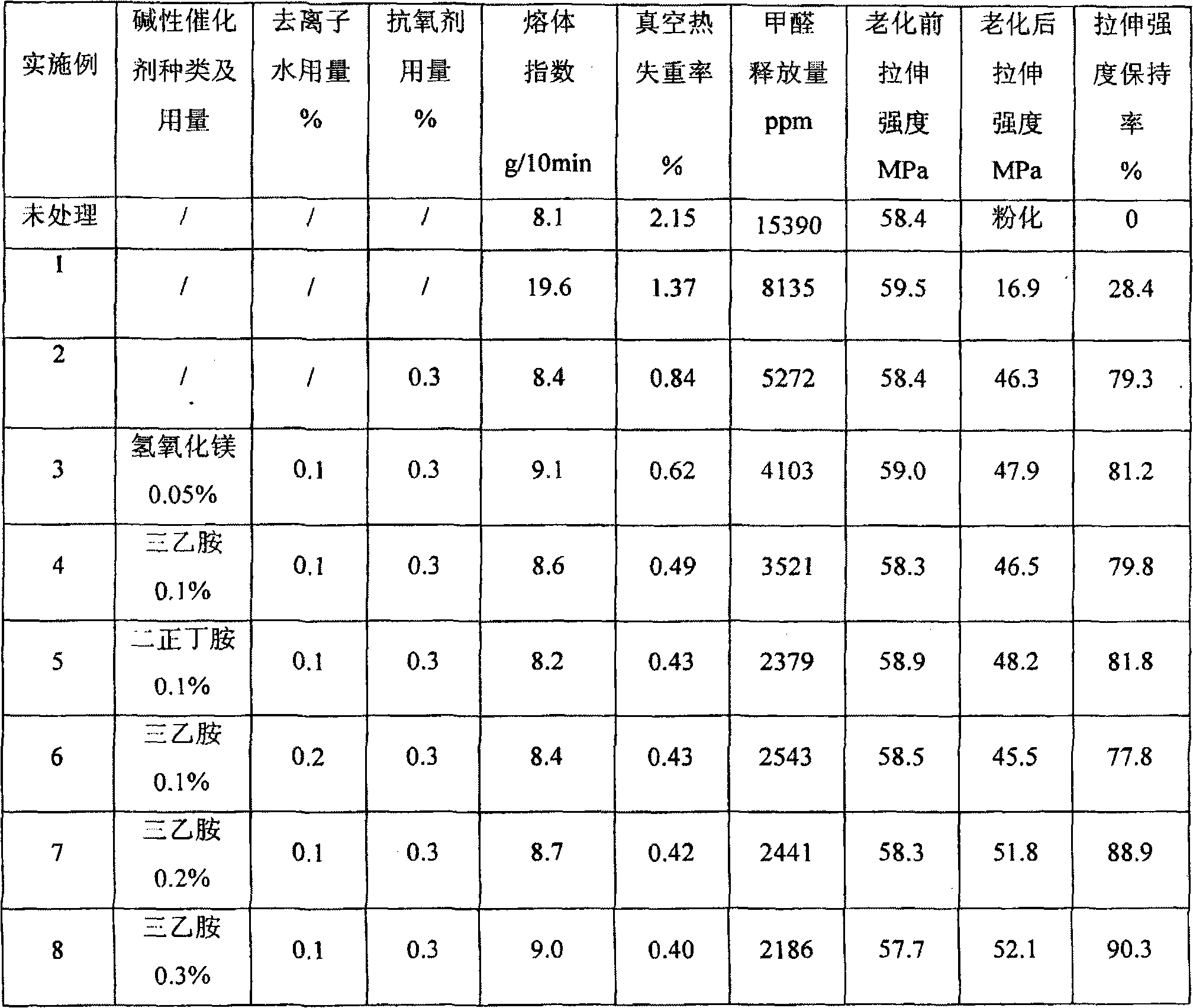

Embodiment 1

[0037] Without adding any additives, the acetal copolymer powder is directly melted and extruded by a vented twin-screw extruder, the processing temperature is 180°C-220°C, the pressure in the vacuum zone is 0.01-0.2bar, and the screw speed is 120 rpm / min, dried at 80°C for 4 hours after granulation.

Embodiment 2

[0039] 10Kg of polyoxymethylene powder and 30 g of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester were uniformly mixed and extruded using a vented twin-screw extruder. The treatment temperature is 180°C-220°C, the pressure in the vacuum zone is 0.01-0.2 bar, the screw speed is 120 rpm, and the pellets are dried at 80°C for 4 hours.

Embodiment 3

[0041] Mix 10Kg of polyoxymethylene powder, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester 30g, magnesium hydroxide 5g, and deionized water 10g evenly and then use exhaust type The twin-screw extruder is melted and extruded, the processing temperature is 180°C-220°C, the pressure in the vacuum zone is 0.01-0.2bar, the screw speed is 120 rpm, and it is dried at 80°C for 4 hours after granulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com